Preparation method of fluorion selective nanofiltration membrane

A nanofiltration membrane, fluoride ion technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of convenient operation, high selectivity, and high consumption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

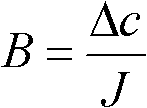

[0020] A polysulfone support membrane made of N, N-dimethylacetamide solution containing 15% polysulfone was put into an aqueous solution of m-phenylenediamine with a mass concentration of 0.5% and a pH value of 8 for 2 minutes; Sodium dodecyl sulfonate at a concentration of 0.05%. The supporting membrane soaked in the m-phenylenediamine solution is rolled with a rubber roller, and the excess solution is removed, and then it is contacted with a solution of trimesoyl chloride with a mass concentration of 0.5% for 20 seconds, and the organic solvent is n-hexane. The film was kept in a vacuum oven at 90° C. for 12 minutes to prepare a polyamide film. The initial performance of the membrane was tested with 500mg / L sodium fluoride aqueous solution under the pressure of 2MPa. The permeability coefficient of the membrane to fluoride ions was 2.139, and the permeability coefficient directly determined the selective permeability of the membrane to fluoride ions. Among them, fluoride io...

Embodiment 2

[0025] Use the polysulfone supporting membrane that contains 15% polysulfone N, N-dimethylacetamide solution to make, put into the aqueous solution of m-phenylenediamine that the mass concentration is 0.2%, pH value is 7 for 3 minutes; Sodium dodecyl sulfonate at a concentration of 0.05%. The supporting membrane soaked in the m-phenylenediamine solution was rolled with a rubber roller to remove the excess solution and then contacted with a solution of trimesoyl chloride with a mass concentration of 0.4% for 30 seconds, and the organic solvent was n-heptane. After the organic solvent was dry, it was contacted with an aqueous solution containing polyethyleneimine with a molecular weight of 600 at a mass concentration of 0.05% for 30 seconds, and the film was placed in an oven at 85°C for 11 minutes. Using 500mg / L sodium fluoride aqueous solution to test the initial performance of the membrane under the pressure of 2MPa, the permeability coefficient of the membrane to fluoride io...

Embodiment 3

[0027] A polysulfone support membrane made of N, N-dimethylacetamide solution containing 18% polysulfone was put into an aqueous solution of m-phenylenediamine with a mass concentration of 0.4% and a pH value of 9 for 1 minute; Sodium dodecyl sulfonate at a concentration of 0.05%. The supporting membrane soaked in the m-phenylenediamine solution was rolled with a rubber roller to remove excess solution and then contacted with a solution containing trimesoyl chloride with a mass concentration of 0.3% for 40 seconds, and the organic solvent was IsoparG. After the organic solvent was dry, it was contacted with an aqueous solution containing polyethyleneimine with a molecular weight of 600 at a mass concentration of 0.1% for 40 seconds, and the film was placed in an oven at 80° C. for 10 minutes. Using 500mg / L sodium fluoride aqueous solution to test the initial performance of the membrane under the pressure of 2MPa, the permeability coefficient of the membrane to fluoride ion is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com