Multifunctional composite adsorbent, and preparation method and application thereof

A composite adsorption, multi-functional technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve problems such as the enhancement of polluting components, and achieve the effects of large adsorption capacity, simple operation, and convenient recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

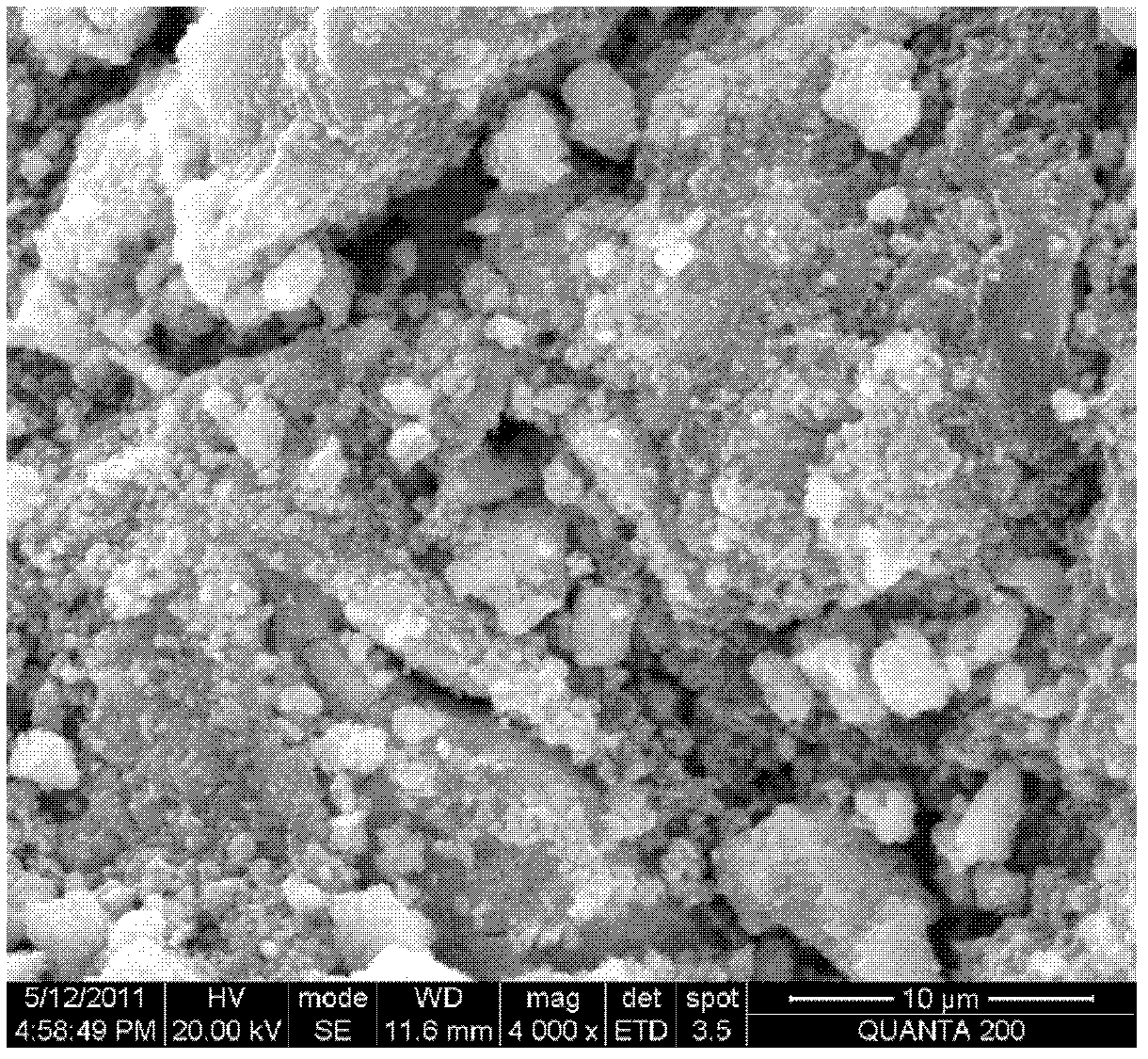

[0033] a kind of like figure 1 The multifunctional composite adsorbent of the present invention shown, this multifunctional composite adsorbent is based on cross-linked chitosan, and cross-linked chitosan is made of heavy metal cadmium ion imprinted chitosan cross-linked by cross-linking agent glutaraldehyde. Formed after linking, the cross-linked chitosan matrix is filled with nano-Fe 3 o 4 and nano TiO 2 , the surface of the multifunctional composite adsorbent is modified by thiourea to form a large number of free amino groups.

[0034] A preparation method of the above-mentioned multifunctional composite adsorbent, comprising the following steps:

[0035] (1) Photocatalytic loading: Weigh 5.0g chitosan powder and add it to 200ml acetic acid solution with a concentration of 2.5%, ultrasonically disperse and dissolve, and add 2.0g nano-TiO 2 powder and 2.5g nano Fe 3 o 4 Powder, mechanically stirred to form a uniform emulsified mixture;

[0036] (2) Ion imprinting: A...

Embodiment 2

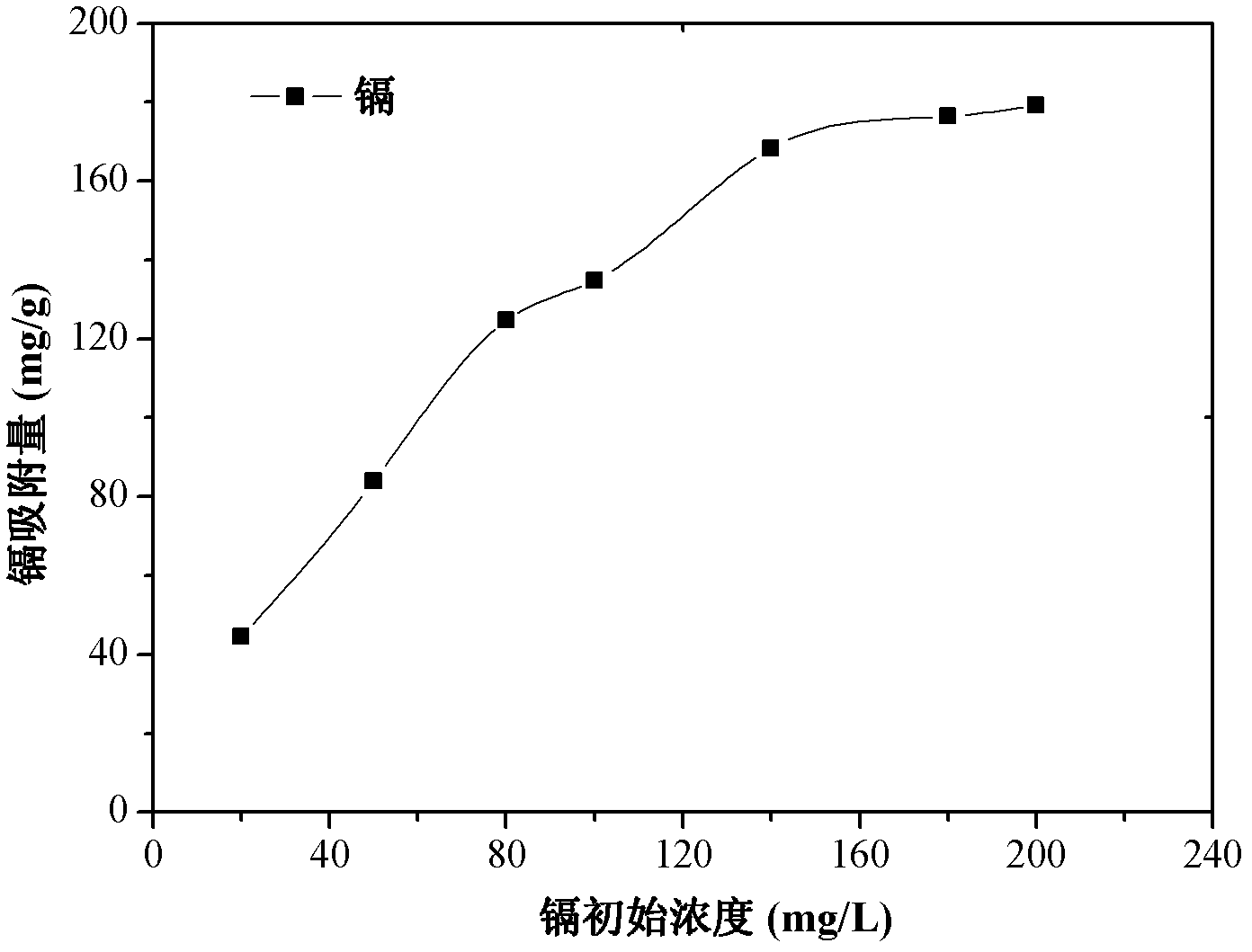

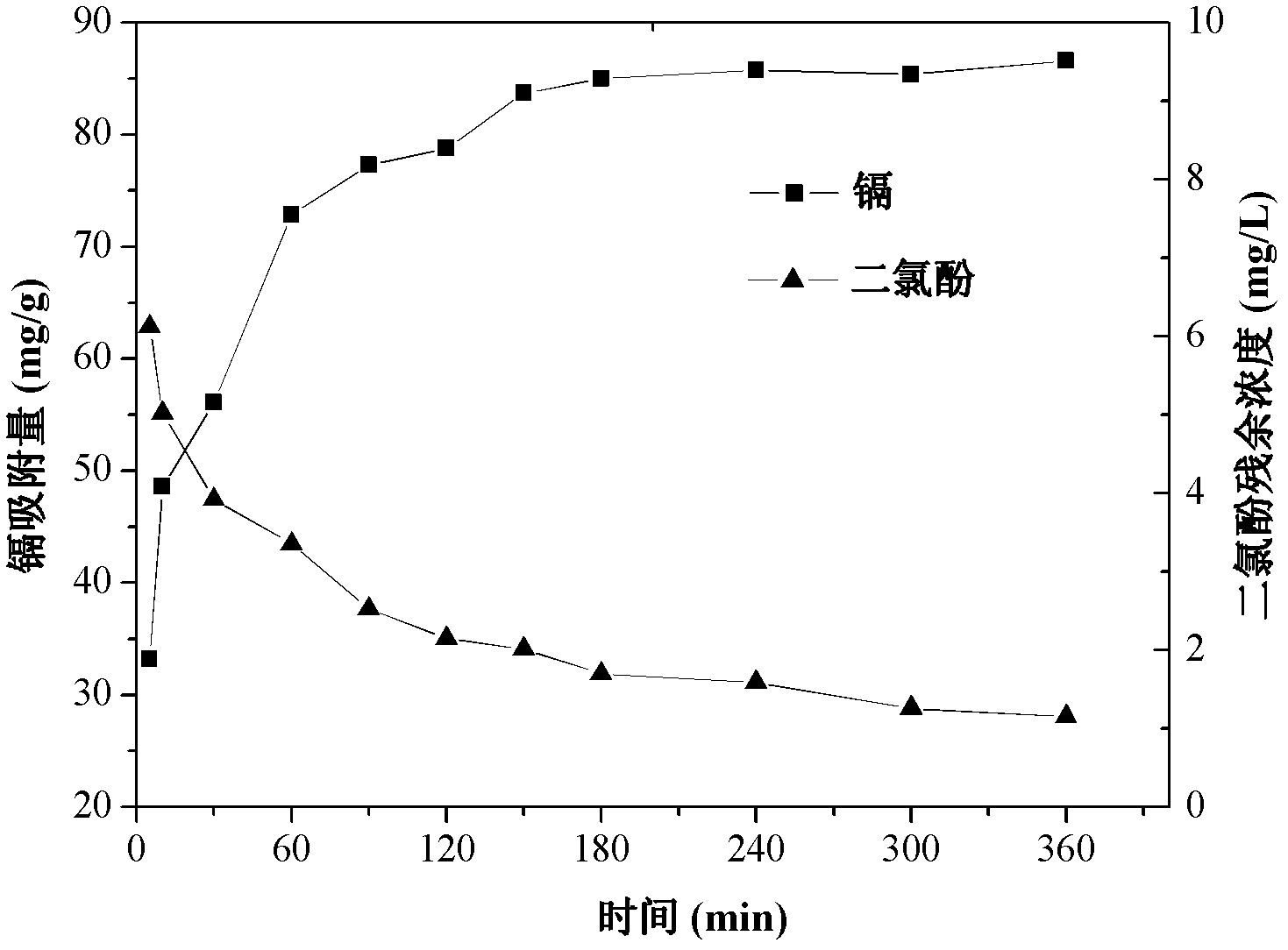

[0040] Embodiment 2: the application of adsorbent in the treatment of composite wastewater

[0041] (1) Different pH values

[0042] The composite wastewater containing cadmium and 2,4-dichlorophenol under different pH value conditions is processed by utilizing the multifunctional composite adsorbent obtained in Example 1, comprising the following steps:

[0043] Choose the composite waste water that the initial concentration of cadmium is 100mg / L and the initial concentration of 2,4-dichlorophenol is 10mg / L, with NaOH (or HNO 3 ) adjust the pH value of the composite wastewater, and prepare nine samples of the composite wastewater to be treated with pH values ranging from 2 to 8, and add the multifunctional composite adsorbent prepared in Example 1 to the nine samples of the composite wastewater to be treated respectively. In, under the temperature condition of 25 ℃, put in the shaker and shake and react for 6h (the shaker speed is 120rpm), after the reaction is completed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com