Inclined plate electroplate device for removing heavy metal from wastewater and manufacturing method of filter board

A technology for electroplating wastewater and production method, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , low energy consumption, the effect of solving the way out problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

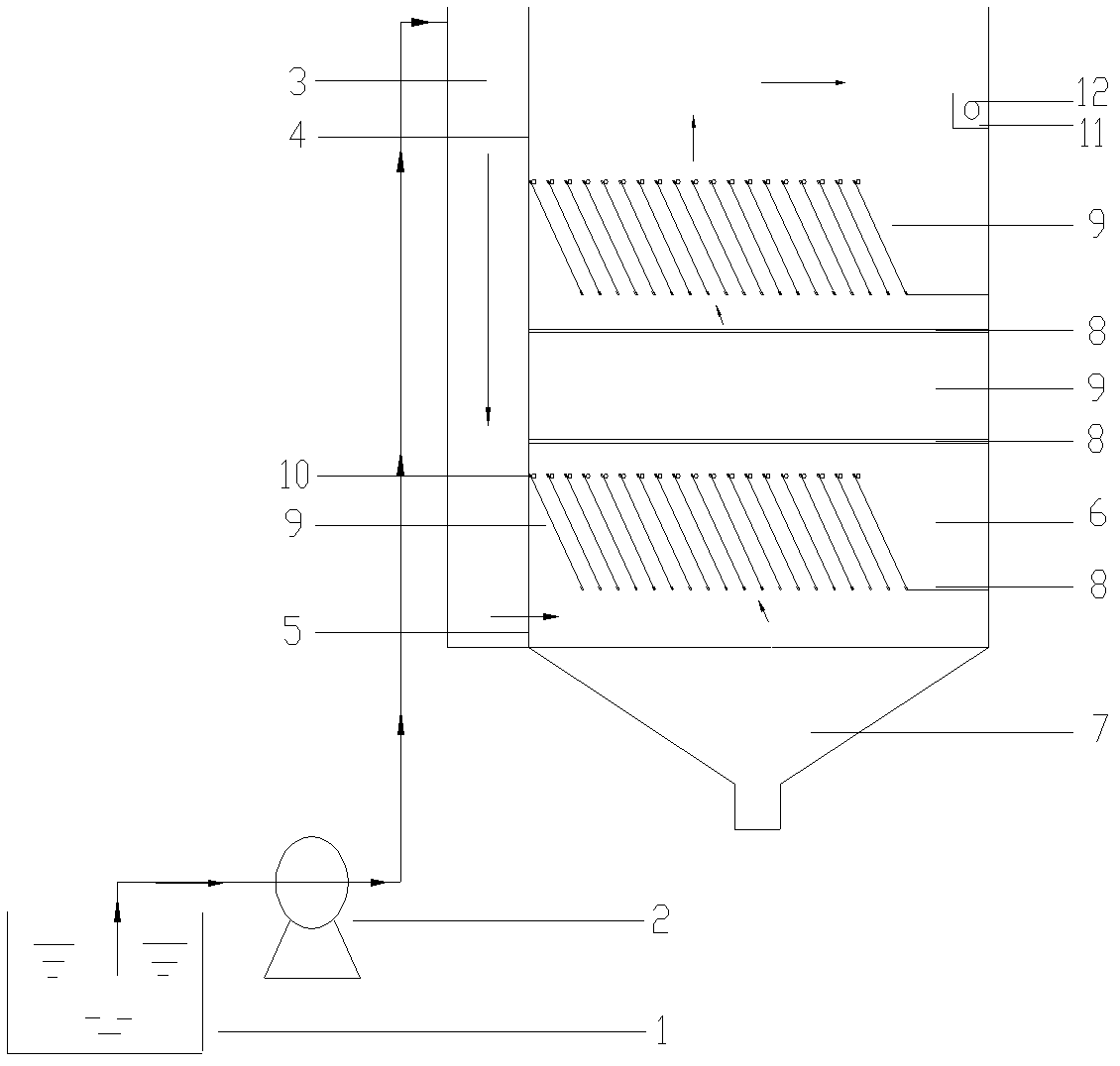

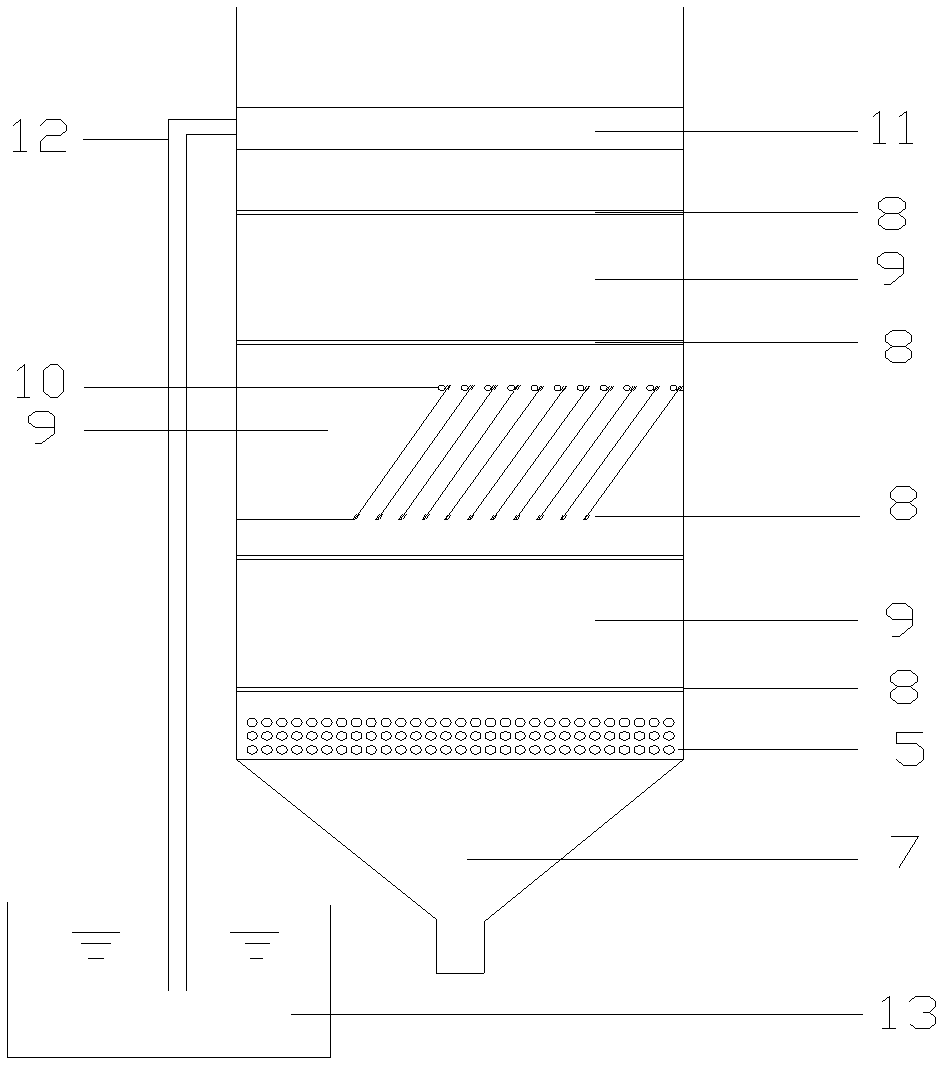

[0034] A slant plate type electroplating wastewater heavy metal removal device, the structure is as follows figure 1 As shown, it includes a water distribution device, an inclined plate reaction device 6 , a flushing device 10 , an effluent collecting device 13 and a sediment collecting device 7 . The water distribution device is mainly composed of a water collection pool 1 and a water distribution pool 3. A peristaltic pump 2 with a flowmeter is provided on the pipeline between the water collection pool 1 and the water distribution pool 3. Between the water distribution pool 3 and the inclined plate reaction device 6 The room is separated by a water distribution plate 4; the main body of the inclined plate reaction device 6 is a box reactor with an open upper part, and there are three groups of filter plates 9 placed obliquely in the reactor, and the adjacent two groups of filter plates are perpendicular to each other, so The upper right of the inclined plate reaction device ...

Embodiment 2

[0039]Embodiment 2: The structure of the inclined plate type electroplating wastewater heavy metal removal device is as described in Embodiment 1, the difference is that the production method of the red mud coal powder filter plate is as follows:

[0040] Weigh 78 parts of red mud, 12 parts of coal powder, 3 parts of expansion agent aluminum powder and 7 parts of water to make a slurry; take 5.5g of the slurry and apply it evenly on the wire mesh mud hanger with a brush, and dry it A raw mud filter plate is obtained; the raw mud filter plate is fired in a muffle furnace; the firing temperature is 310° C., and the firing time is 25 minutes. The filter plate has a removal rate of more than 95% for copper-containing electroplating wastewater.

Embodiment 3

[0041] Embodiment 3: The structure of the inclined plate type electroplating wastewater heavy metal removal device is as described in Embodiment 1, the difference is that the production method of the red mud coal powder filter plate is as follows:

[0042] Weigh 73 parts of red mud, 15 parts of coal powder, 2 parts of expansion agent aluminum powder and 10 parts of water to make a slurry; take 8.0g of the slurry and apply it evenly on the wire mesh mud hanger with a brush, and dry it to make a slurry. A raw mud filter plate was obtained; the raw mud filter plate was fired in a muffle furnace at a firing temperature of 350° C. and a firing time of 20 minutes. The filter plate has a removal rate of more than 99% for zinc-containing electroplating wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com