Waterborne acrylic resin and metal flashing paint applying same

A technology of water-based acrylic and flash paint, applied in the direction of coating, etc., can solve the problems of low solid content, high cost, and expensive polyurethane resin, and achieve the effects of improving sagging resistance, good coordination, and overcoming high VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

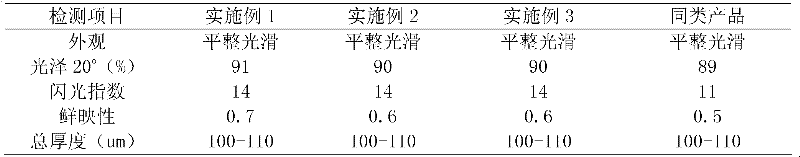

Examples

Embodiment 1

[0032] 1. Synthesis of Waterborne Acrylic Resin

[0033] (1) Prepare emulsifier solution: Add 3.3g sodium dodecylsulfonate and 1.8g nonylphenyl polyoxyethyl ether to a beaker, then add 20mL deionized water to fully dissolve it; prepare the initiator Solution: add 0.8g ammonium persulfate and 20mL deionized water to the beaker to fully dissolve; prepare mixed monomer: mix 70-100g butyl acrylate with 20g methyl methacrylate;

[0034] (2) Add 2 / 3 of the emulsifier solution and 1 / 3 of the initiator solution into a nitrogen-protected four-neck flask, add 100mL of deionized water, and heat up while stirring; add 1 / 5 of the mixed monomer and continue stirring Raise the temperature to 84°C, keep the temperature constant, and react for 15 minutes to form a "seed" emulsion;

[0035] (3) Divide the remaining mixed monomer into two equal parts, add 13g butyl methacrylate, 1.2g methacrylic acid, 1.3g ethylene glycol dipropylene ester to the first part; add 10g methacrylic acid to the seco...

Embodiment 2

[0043] 1. Synthesis of Waterborne Acrylic Resin

[0044] (1) Add 2.2g of sodium dodecylsulfonate, 1.2g of nonylphenyl polyoxyethyl ether, 0.3g of ammonium persulfate and 20g of deionized water into a four-necked flask protected by nitrogen, and stir to fully dissolve , add 4g of methyl methacrylate and 17g of butyl acrylate while stirring, then gradually raise the temperature to 84°C, and react at constant temperature for 15 minutes;

[0045] (2) 8g methyl methacrylate, 13g butyl methacrylate, 34g butyl acrylate, 1.2g methacrylic acid and 1.1g trihydroxypropane triacrylate were mixed and stirred and then added dropwise to a four-necked flask for 1.5 hours After dropping, add 7.5g 4% ammonium persulfate solution and 4.2g emulsifier solution (containing 0.6g sodium dodecylsulfonate and 0.3g nonylphenyl polyoxyethyl ether) dropwise;

[0046] (3) 18g methyl methacrylate, 34g butyl acrylate, 5g acrylamide, 9g hydroxypropyl acrylate and 4.5g acetoacetoxy ethyl methacrylate were mix...

Embodiment 3

[0053] 1. Synthesis of Waterborne Acrylic Resin

[0054] (1) Add 2.2g of sodium dodecylsulfonate, 1.2g of nonylphenyl polyoxyethyl ether, 0.3g of ammonium persulfate and 20g of deionized water into a four-necked flask protected by nitrogen, and stir to fully dissolve , add 4g of methyl methacrylate and 16g of ethyl acrylate while stirring, then gradually raise the temperature to 84°C, and react at constant temperature for 15 minutes;

[0055] (2) Mix and stir 8g of methyl methacrylate, 13g of butyl methacrylate, 30g of ethyl acrylate, 1.0g of acrylic acid and 1.5g of hexanediol diacrylate and drop them into a four-necked flask for 1.5 hours. , while adding dropwise 7.5g 4% ammonium persulfate solution and 4.2g emulsifier solution (containing 0.6g sodium dodecylsulfonate and 0.3g nonylphenyl polyoxyethyl ether);

[0056] (3) 18g methyl methacrylate, 30g ethyl acrylate, 5g acrylamide, 9g hydroxyethyl methacrylate and 4.5g acetoacetoxyethyl methacrylate were mixed and stirred an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com