Method for preparing high purity polysorbate 80 through esterification of oleic acid and mixture of respectively etherified starting materials

A polysorbate, high-purity technology, applied in the field of preparing high-purity polysorbate 80 by separately etherifying the starting materials and then mixing them with oleic acid esterification, can solve the problems of uncertainty, large experimental workload, etc., and achieve The effect of uniform ether chain, high purity and content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

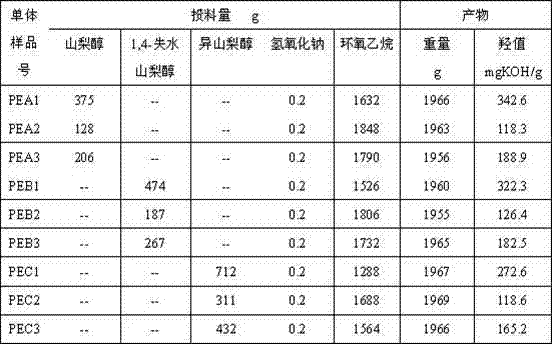

[0032] Embodiment 1, the method for preparing high-purity polysorbate 80 after etherification and oleic acid esterification of starting materials respectively: add the sorbitol of the amount shown in table 1 in 3L stainless steel autoclave, 0.2g sodium hydroxide , after replacing with nitrogen, heat up and depressurize for dehydration, then use nitrogen to slowly press the amount of ethylene oxide shown in Table 1 into the autoclave for addition polymerization, control the speed of adding ethylene oxide, and maintain the temperature of the kettle at 140°C~ 150℃, pressure 0.4Kg / m 2 , after adding ethylene oxide, aged for 2 hours, the pressure in the kettle was reduced to normal pressure, the discharge was measured, and the hydroxyl value was sampled to obtain the sorbitol polyoxyethylene ether monomer.

[0033] In the same way, add 1,4-sorbitol and isosorbide to ethylene oxide for addition polymerization to obtain 1,4-sorbitol polyoxyethylene ether and isosorbide polyoxyethylen...

Embodiment 2

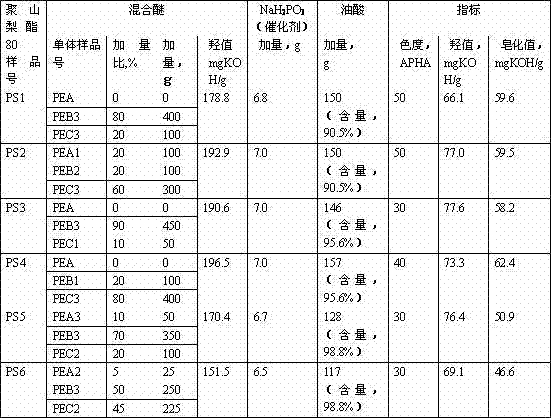

[0037] In a 1000ml three-necked flask, add a certain amount of PEA, PEB, and PEC respectively, and simply mix them evenly to obtain a mixed ether with a hydroxyl value in the range of 150mgKOH / g~200mgKOH / g. %) under the protection of nitrogen, stir and heat up to 220°C, heat preservation and dehydration reaction until the acid value is less than 2.0mgKOH / g. Cool down with decolorizing earth and diatomaceous earth, filter, and filter through a 0.22μ filter element to remove bacteria and remove pyrogens to obtain light yellow to colorless and transparent polysorbate 80. Sampling and analysis of chromaticity, hydroxyl value and saponification value. The experimental results are shown in Table 2:

[0038] Table 2 Experimental results of polysorbate 80

[0039]

[0040] Application test:

[0041] Accurately weigh 1.0 g of zedoary oil, 9 g of polysorbate 80, and 30 g of distilled water in a 50 ml glass ampoule, melt and seal the ampoule, and shake it in a shaker to mix well...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com