Salt-resistant strong-inhibitive reservoir-protecting drilling fluid

A technology of strong inhibition and drilling fluid, applied in the field of salt resistance, protection of reservoir drilling fluid, strong inhibition, and additives, it can solve the problems of borehole shrinkage, difficult rheological control, and well wall spalling, etc., to improve the pressure bearing. Ability, inhibition of hydration and dispersion, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

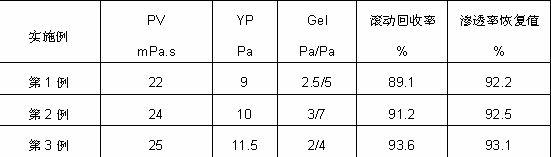

Embodiment 1

[0009] Example 1. 2 Kg of bentonite, 1 Kg of anti-saline soil, 0.1 Kg of soda ash, 100 Kg of water, 0.8 Kg of viscosity enhancing agent ST-MH, 3 Kg of fluid loss reducer, 0.2 Kg of shale inhibitor SET-H, organic Compound salt BPC 3 Kg, bridging plugging agent MF-II 2 Kg and biological enzyme storage agent CVS 2 Kg are mixed into the drilling fluid of the present invention.

Embodiment 2

[0010] Example 2. 3 Kg of bentonite, 1 Kg of anti-saline soil, 0.15 Kg of soda ash, 100 Kg of water, 0.6 Kg of viscosity enhancing agent ST-MH, 2 Kg of fluid loss reducer, 0.4 Kg of shale inhibitor SET-H, organic Compound salt BPC 2 Kg, bridging plugging agent MF-II 4 Kg and biological enzyme storage agent CVS 2 Kg are mixed into the drilling fluid of the present invention.

Embodiment 3

[0011] Example 3. 4 Kg of bentonite, 3 Kg of anti-saline soil, 0.2 Kg of soda ash, 100 Kg of water, 0.4 Kg of viscosity enhancing agent ST-MH, 2 Kg of fluid loss reducer, 0.6 Kg of shale inhibitor SET-H, and 0.6 Kg of organic Compound salt BPC 2 Kg, bridging plugging agent MF-II 6 Kg and biological enzyme storage agent CVS 2 Kg are mixed into the drilling fluid of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com