Composition for treating friction pair and preparation method thereof

A technology of composition and friction pair, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of crisis production personnel, strong corrosiveness and irritation, inability to prepare and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of the composition of the present invention

[0027] Weigh 1000g of kaolin raw ore, pulverize, sieve, then add water to make slurry, select the kaolin slurry suspended in water step by step, filter, and dry to obtain kaolin fine powder.

[0028] Weigh 500g of serpentine ore, crush it, remove non-minerals, and then crush it into fine powder to get final product.

[0029] Weigh 100g of borax, crush it, add 100ml of 10°C cold water, soak for 1 hour, stir from time to time, filter, repeat the operation twice, filter, remove the filtrate, then add 200ml of water, heat to boiling, filter, place, and precipitate crystals , filter, take the crystals, and dry them.

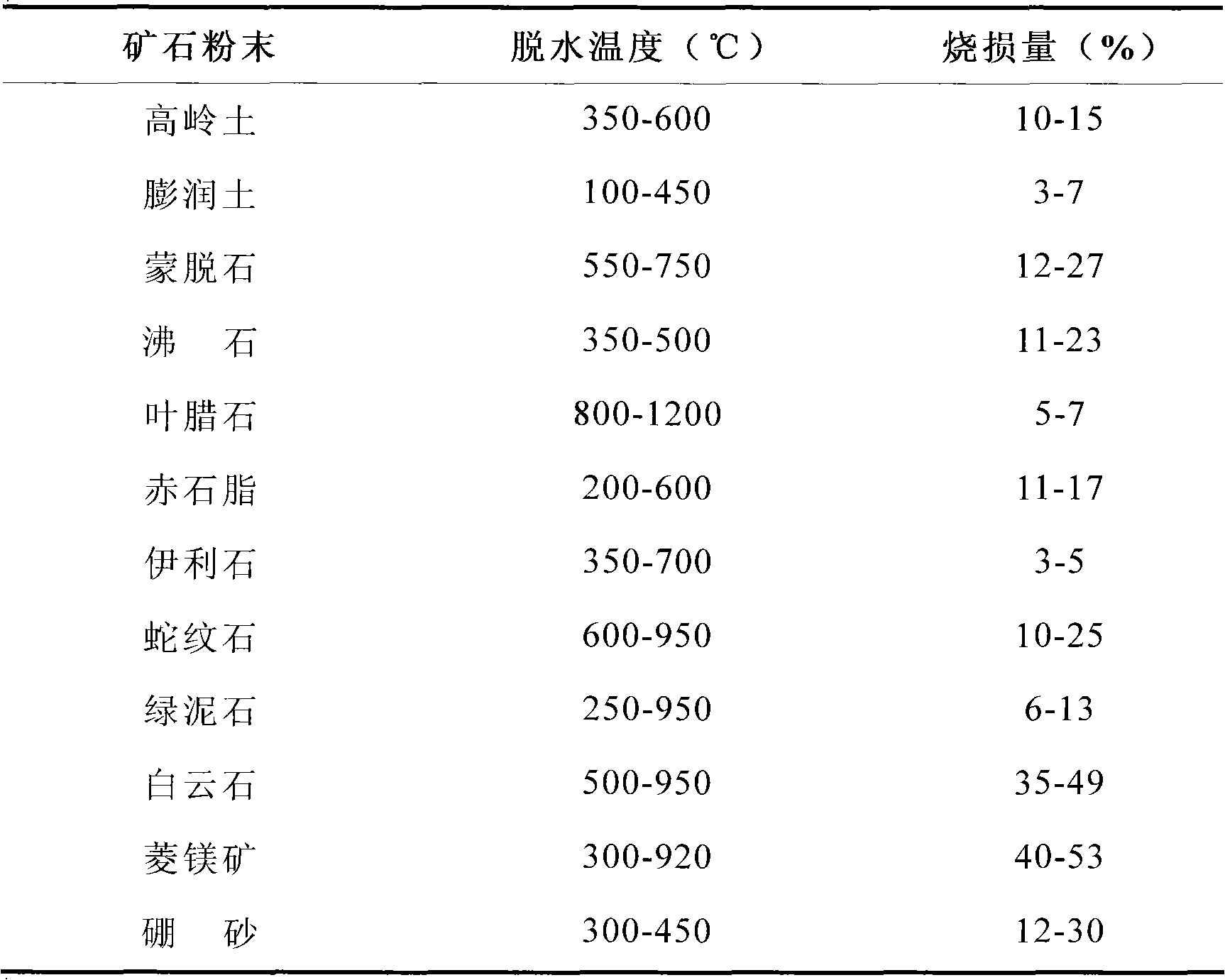

[0030] Weigh the kaolin powder respectively, place it in a muffle furnace, heat it to 600-700°C, calcinate it for 5 hours, take it out, and put it at room temperature to obtain the dehydrated kaolin powder. Take serpentine powder, heat it in a muffle furnace to 600-650°C, calcinate for 4 hours, take...

Embodiment 2

[0041] 1. Preparation of the composition of the present invention

[0042] Weigh 1000g of bentonite raw ore, crush it, add 5 times the amount of water, stir for 20 minutes to disperse it into fine particles, filter through a 60-mesh sieve, remove the coarse sand in the bentonite, and then place the bentonite slurry in an ultrasonic cleaner for ultrasonication After 30 minutes, filter through a 200-mesh sieve, and dry the filtrate to obtain fine bentonite powder.

[0043] Take 500g of talc ore, crush it into ultrafine powder with a pulverizer, and the particle diameter is 10-25μ; add 5 times the amount of water to suspend, divide the upper suspension according to the water flying method, filter, and dry it.

[0044] Take bentonite fine powder, heat it in a muffle furnace to 250-300°C for 5 hours, take it out and let it cool to room temperature, weigh it, and calculate the lost weight.

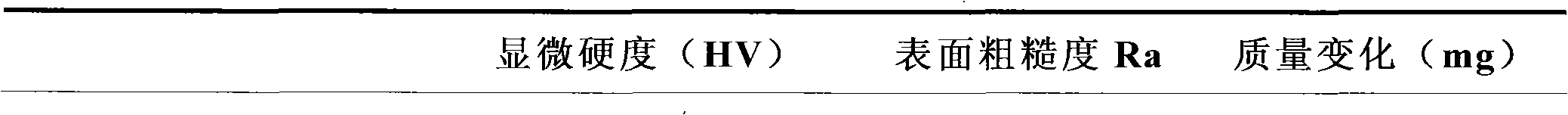

[0045] Weigh 750g of dehydrated superfine bentonite powder, 180g of dehydrated talc superfi...

Embodiment 3

[0057] 1. Preparation of the composition of the present invention

[0058] Weigh 1000g of red stone ore, crush it into coarse powder, then add 5 times the amount of water, stir to disperse it into tiny particles, pass through a 200-mesh sieve, place the filtrate to precipitate, take the precipitate, and dry it to obtain it.

[0059] Weigh 500 g of stevensite ore and 200 g of boronite ore, and pulverize them into superfine powder with a ball mill respectively, with a particle diameter of 10-25 μm.

[0060] Put red stone resin ultrafine powder, stevensite ultrafine powder, and boronite ultrafine powder in a muffle furnace and heat to 450-700°C for 2 hours, take it out and put it at room temperature, weigh it, and calculate the lost weight .

[0061] Respectively weigh 700g of dehydrated red stone fat superfine powder, 230g of dehydrated stevensite superfine powder, 60g of boormagnesite powder, and 10g of butyl titanate, put them into a high-energy ball mill and grind them until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com