Method using xylose production waste liquid to produce acetone and butanol

A technology of xylose mother liquor and xylose, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high production cost, complicated process, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

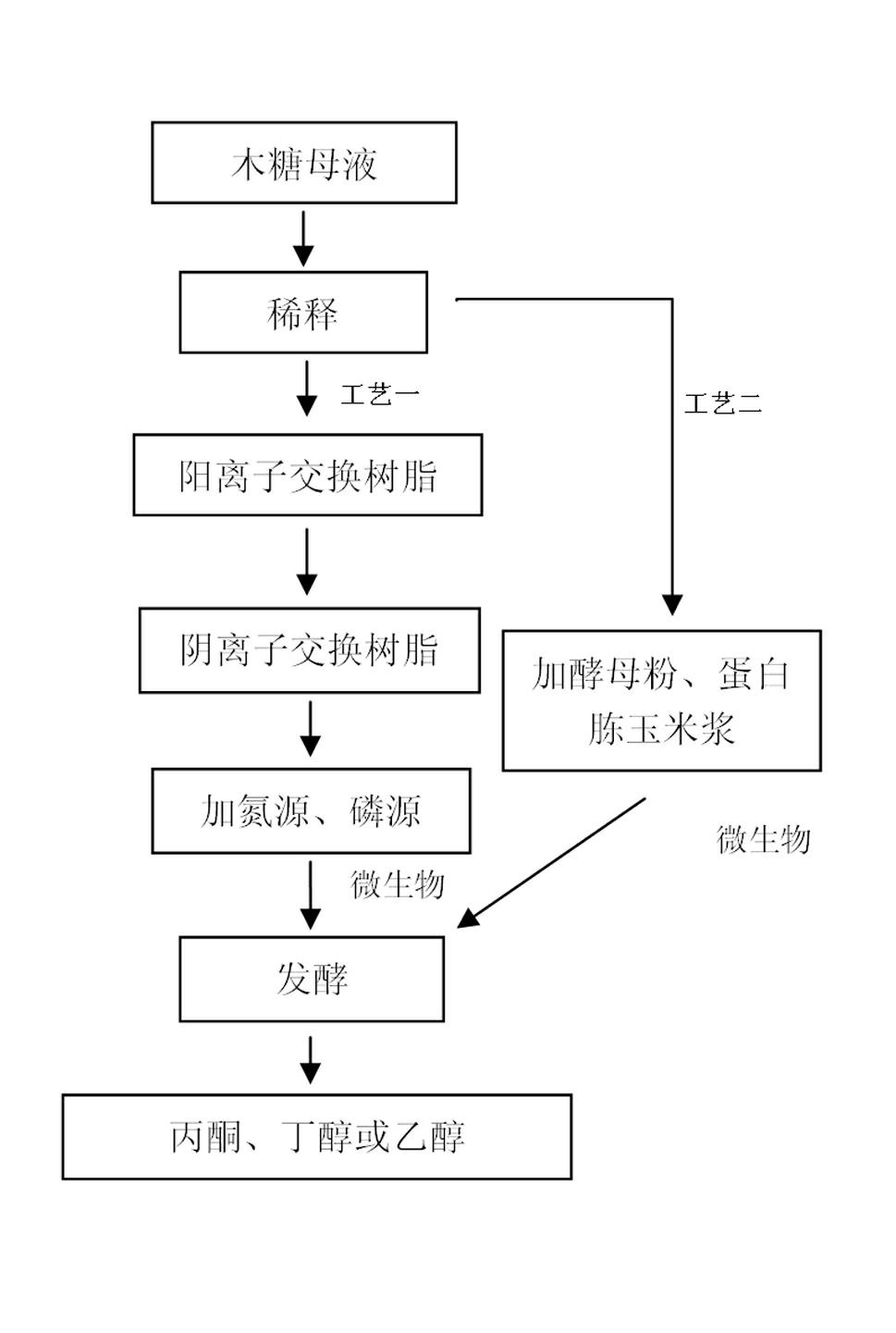

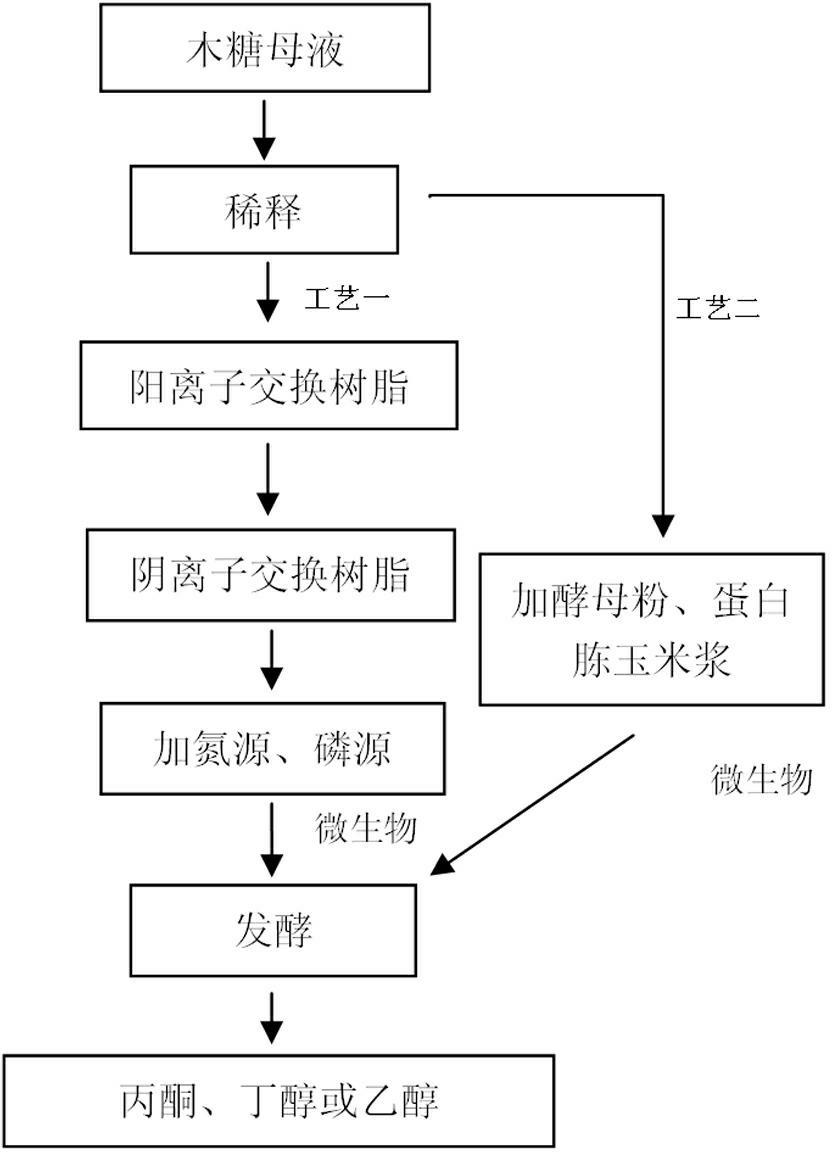

Method used

Image

Examples

Embodiment 1

[0021] ATCC55025 strain and CICC8016 use xylose mother liquor medium to produce acetone butanol:

[0022] Preparation of Clostridium beijerinckii Clostridium beijerinckii ATCC55025. Transfer the above-mentioned strain inoculation to the anaerobic tube of glucose seed culture medium. After the transfer, put the anaerobic tube into a water bath at 100℃ and boil it, immediately cool to room temperature, fill it with nitrogen, and let stand anaerobic culture at 37℃16 ~18h is the fermented seed liquid.

[0023] The above-mentioned glucose seed medium refers to: 1L contains 3 g yeast extract, 10 g beef extract, 10 g tryptone, 5 g glucose, 1 g soluble starch, 5 g sodium chloride, and 3 g sodium acetate trihydrate. L-cysteine 0.5 g, sterilized at 115°C for 15 minutes.

[0024] Clostridium acetobutylicum Clostridium acetobutylicum CICC8016. Transfer the above strain inoculation to the anaerobic tube of 5% corn mash seed culture medium. After the transfer, put the anaerobic tube into a ...

Embodiment 2

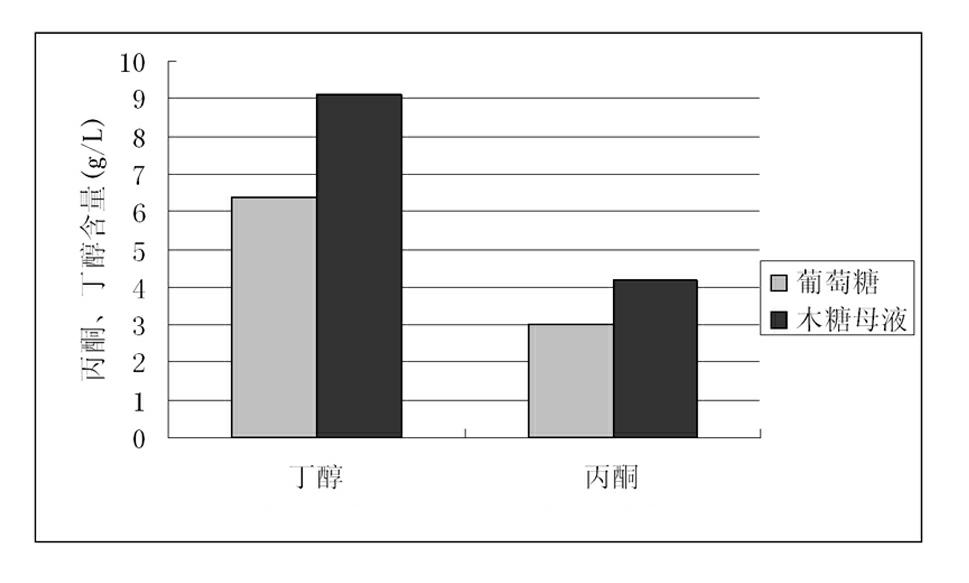

[0031] The ATCC55025 strain uses xylose mother liquor and glucose to ferment to produce acetone and butanol:

[0032] Clostridium beijerinckii Clostridium beijerinckii ATCC55025 in the anaerobic flask, xylose mother liquor fermentation medium and glucose fermentation medium for acetone butanol fermentation comparison.

[0033] Using the seed liquid prepared in Example 1, according to the inoculum amount of 5%, it was transferred to a fermentation medium containing 50g / L glucose. After the transfer, it was filled with nitrogen and allowed to stand anaerobic culture at 37°C for more than 72 hours, which is acetone , Butanol fermentation product.

[0034] The above-mentioned glucose fermentation medium has the following ingredients: 5g glucose (the medium contains 48.3g / L glucose as determined by HPLC after sterilization), 0.1g yeast powder, KH 2 PO 4 0.05g, K 2 HPO 4 0.05g, ammonium acetate 0.22g, MgSO 4 ·7H 2 O 0.02g, MnSO 4 ·7H 2 O 0.001g, NaCl 0.001g, FeSO 4 ·7H 2 O 0.001g, dilut...

Embodiment 3

[0040] Different concentrations of xylose mother liquor is directly added with 0.2% yeast powder to ferment to produce acetone and butanol:

[0041] Prepare Clostridium beijerinckii as described in Example 1 Clostridium beijerinckii ATCC55025 seed liquid. That is, transfer the above-mentioned strain inoculation to the anaerobic tube of the glucose seed culture medium. After the transfer, put the anaerobic tube into a 100°C water bath to boil, immediately cool to room temperature, fill with nitrogen, and let stand anaerobic at 37°C. Cultured for 16h is the fermentation seed liquid.

[0042] Xylose mother liquor optimization optimization medium: configure 5 bottles of 100mL medium, in which the xylose mother liquor is directly diluted according to the concentration gradient of 6% (v / v), and 0.2g yeast powder is added respectively, the pH is natural, and it is connected to ATCC55025 The fermented seed liquid was fermented for 72 hours, and the content of acetone and butanol was dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com