Silicon-carbon composite anode material for lithium ion battery and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as affecting cycle performance, pulverization and peeling of electrode materials, etc., to improve cycle performance, improve mass specific capacity, and simple operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

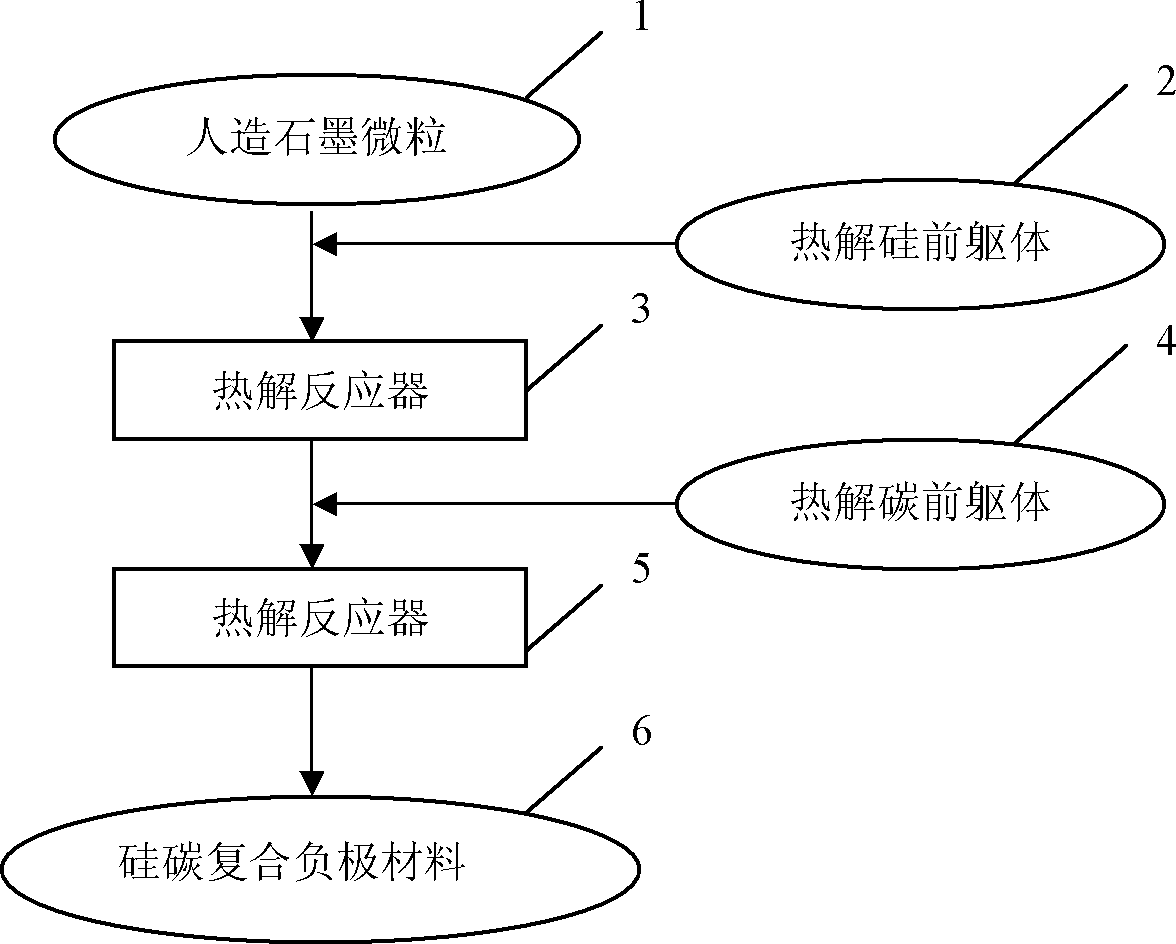

[0024] Preparation of silicon-carbon composite materials. The core material artificial graphite particles with a purity of 99.99% are evenly distributed in the reaction tank of the pyrolysis reactor. The size of the graphite particles is 0.1-1 μm, and the reaction tank is placed in the constant temperature zone of the pyrolysis reactor. The temperature of the pyrolysis reactor was raised to 500°C under the protection of a high-purity argon atmosphere, the protective argon gas source was turned off, the pyrolysis silicon precursor silane gas source was turned on, and the pyrolysis reactor was entered at a flow rate of 50 ml / min, and the reaction temperature was maintained at 3 After 1 hour, the silane gas source was turned off, and the argon gas was used for protection. Raise the temperature of the reactor to 800°C, turn off the argon gas source, turn on the pyrolysis carbon precursor methane, enter the pyrolysis reactor at a flow rate of 50 ml / min, keep the reaction temperatur...

Embodiment 2

[0026] Preparation of silicon-carbon composite materials. The artificial graphite particles of the core material are 5-10 μm, and the high-temperature pyrolysis reaction method is the same as in Example 1. The pyrolysis silicon precursor uses ethylsilane, and the pyrolysis time is 1 hour. The pyrolysis carbon precursor uses acetylene, and the pyrolysis time is After 2 hours, the obtained silicon-carbon composite material has a silicon content of 18% (wt), a core material graphite particle content of 46% (wt), and a shell material pyrolytic carbon content of 36% (wt). The battery performance test is the same as that in Embodiment 1. It has been determined that the reversible cycle capacity of the prepared silicon-carbon composite anode material is more than 600 mAh / g, there is basically no capacity decline for more than 50 charge-discharge cycles, and the charge-discharge Coulombic efficiency is close to 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com