One-component self-drying acrylic acid grafted epoxy ester aqueous dispersion coating and its preparation method

An acrylic acid grafting and epoxy ester technology, applied in the direction of coating, can solve the problems of easy hydrolysis and fracture, limit wide application, etc., and achieve the effects of strong adhesion, bright and smooth film formation, and simple and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

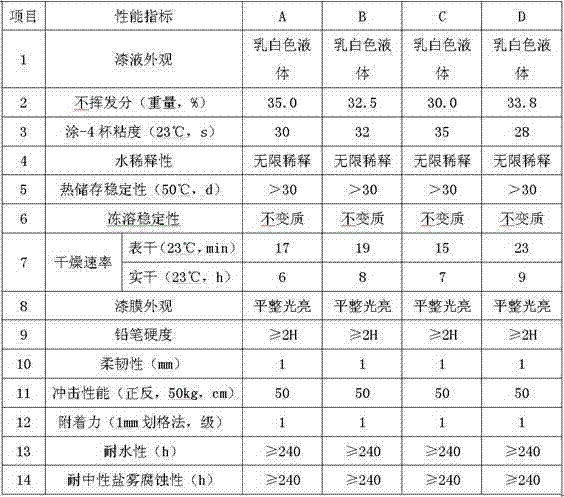

Examples

Embodiment 1

[0025] 220.5g of linolenic acid, 49.5g of dehydrated castor oil fatty acid, 335.5g of E-12 epoxy resin, 0.60g of zinc oxide and 42g of xylene are dropped into the reaction kettle, and the temperature is slowly raised and the nitrogen flow is passed. 2 Ventilation was stopped after half an hour. When the temperature rises to 110°C, try to start stirring, and continue to slowly heat up to 205°C, then start the esterification with heat preservation. During the esterification process, xylene can take out the water vapor from the esterification, and condense and reflux through the oil-water separator (containing the bottom xylene). After the reaction until the acid value is less than 6mgKOH / g, xylene is extracted by vacuum distillation. Then the temperature was lowered to 120° C., and 50 g of co-solvent propylene glycol methyl ether and 125 g of n-butanol were added to maintain the temperature at 115° C. Take 28.0g of acrylic acid, 50g of methyl methacrylate, 50g of styrene, 40.5...

Embodiment 2

[0029] Put 216.5g of linolenic acid, 270.8g of E-12 epoxy resin, 0.50g of zinc oxide and 28g of xylene into the reaction kettle, slowly heat up and pass through N 2 Ventilation was stopped after half an hour. When the temperature rises to 110°C, try to start stirring, and continue to slowly heat up to 210°C, then start the esterification with heat preservation. During the esterification process, when the solvent volatilizes, the water vapor released from the esterification can be taken out, and condensed and refluxed through the oil-water separator (containing the bottom xylene). After the reaction until the acid value is less than 6mgKOH / g, xylene is extracted by vacuum distillation. Then the temperature was lowered to 120° C., and 35 g of co-solvent propylene glycol butyl ether and 104 g of propylene glycol methyl ether were added to maintain the temperature at 120° C.

[0030] Take 22.8g of acrylic acid, 81.4g of methyl methacrylate, 32.2g of n-butanol, and 4.5g of benzoy...

Embodiment 3

[0034] Put 67.5g of linolenic acid, 67.5g of oleic acid, 165.5g of E-14 epoxy resin, 0.35g of zinc oxide and 25g of xylene into the reactor, slowly heat up and pass N 2 Ventilation was stopped after half an hour. When the temperature rises to 110°C, try to start stirring, and continue to slowly heat up to 205°C, then start the esterification with heat preservation. During the esterification process, xylene can take out the water vapor from the esterification, and condense and reflux through the oil-water separator (containing the bottom xylene). After the reaction until the acid value is less than 6mgKOH / g, xylene is extracted by vacuum distillation. Then the temperature was lowered to 120° C., and 17 g of co-solvent dipropylene glycol butyl ether and 68 g of n-butanol were added to maintain the temperature at 117° C. Take 15.5g of acrylic acid, 24.5g of methyl methacrylate, 24.5g of styrene, 20.2g of n-butanol, and 2.6g of benzoyl peroxide (BPO) and mix them evenly. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com