Intestinal health food and preparation method thereof

A health and food technology, applied in food preparation, food science, application, etc., can solve the problems that the activity of bifidobacteria is easily affected by the external environment, and the living bacteria are not easy to preserve, so as to promote the proliferation of beneficial bacteria and calcium absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

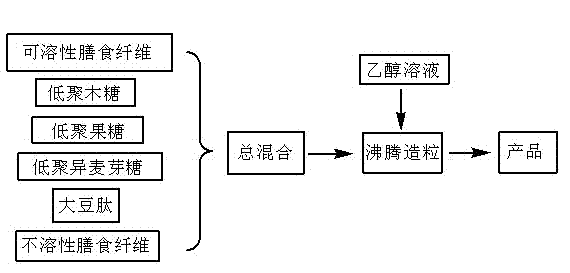

[0038] Example 1, see image 3

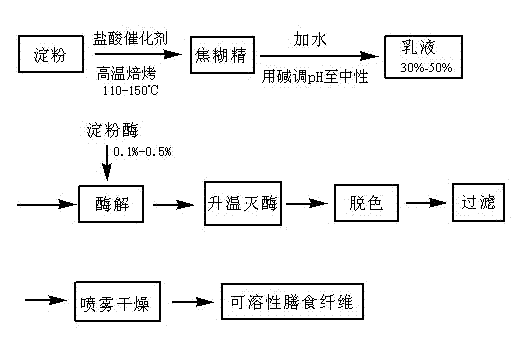

[0039] A) Soluble dietary fiber preparation steps (see figure 1 ):

[0040] (1) Using cassava starch as raw material, add hydrochloric acid with 0.3% starch weight by spraying method, bake at 120°C for 4 hours at high temperature to obtain pyrodextrin;

[0041] (2) Add water to the pyrodextrin to make a 40% emulsion, then adjust the pH to neutral with sodium hydroxide;

[0042] (3) Add 0.2% α-amylase by weight of starch, and perform enzymatic hydrolysis at 70°C for 8 hours;

[0043] (4) Heat up to 120°C to inactivate the enzyme, decolorize with activated carbon and filter;

[0044] (5) Finally, the filtrate is spray-dried to obtain soluble dietary fiber.

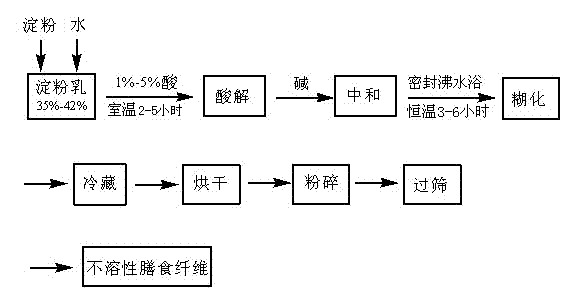

[0045] B) Insoluble dietary fiber preparation steps (see figure 2 ):

[0046] (1) Mix cornstarch and water into 40% starch milk;

[0047] (2) Add hydrochloric acid of 1% by weight of starch, acid hydrolyze at room temperature for 3 hours;

[0048] (3) After adjusting the pH to neutr...

Embodiment 2

[0054] Example 2, see Figure 4

[0055] A) Soluble dietary fiber preparation steps (see figure 1 ):

[0056] (1) Using potato starch as raw material, add hydrochloric acid with 0.5% starch weight by spraying method, bake at 130°C for 2 hours at high temperature to obtain pyrodextrin;

[0057] (2) Add water to the pyrodextrin to make a 30% emulsion, then adjust the pH to neutral with sodium carbonate;

[0058] (3) Add 0.3% β-amylase by weight of starch, and enzymatically hydrolyze at 80°C for 6 hours;

[0059] (4) Heat up to 130°C to inactivate the enzyme, decolorize with activated carbon and filter;

[0060] (5) Finally, the filtrate is spray-dried to obtain soluble dietary fiber.

[0061] B) Insoluble dietary fiber preparation steps (see figure 2 ):

[0062] (1) Make tapioca starch and water into 39% starch milk;

[0063] (2) Add sulfuric acid with 2% weight of starch, acid hydrolyze at room temperature for 4 hours;

[0064] (3) After adjusting the pH to neutral with...

Embodiment 3

[0071] Example 3 (see image 3 )

[0072] A) soluble dietary fiber preparation steps (see figure 1 ):

[0073] (1) Using wheat starch as raw material, add 0.8% hydrochloric acid of starch weight by spraying method and bake at 140°C for 2 hours to obtain pyrodextrin;

[0074] (2) Add water to the pyrodextrin to make a 30% emulsion, then adjust the pH to neutral with sodium carbonate;

[0075] (3) Add 0.5% pullulanase by weight of starch, and enzymolyze at 90°C for 7 hours;

[0076] (4) Heat up to 140°C to inactivate the enzyme, decolorize with activated carbon and filter;

[0077] (5) Finally, the filtrate is spray-dried to obtain soluble dietary fiber.

[0078] B) insoluble dietary fiber preparation step (see figure 2 ):

[0079] (1) Mix wheat starch and water into 38% starch milk;

[0080] (2) Add phosphoric acid of 5% by weight of starch, acid hydrolyze at room temperature for 5 hours;

[0081] (3) After adjusting the pH to neutral with potassium hydroxide, gelatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com