Controllable preparation method of fullerene sub-micron tube

A fullerene submicron and fullerene technology, applied in nanotechnology and other directions, can solve the problems of inability to prepare submicron tubes, failure to realize controllable preparation of submicron tubes, etc., and achieve a process method that is easier to control and easy to operate. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for the controllable preparation of fullerene submicron tubes, comprising the following steps;

[0031] (1) Weigh 0.01g of C60 (purity>99.5%) powder into a clean transparent glass bottle, measure 10ml of pyridine and mix it with C60 powder in the glass bottle, and seal the glass bottle. Put the above solution into an ultrasonic container, control the temperature of the water bath at 8°C with ice water, and ultrasonically sonicate with 100W power for 20min, so as to fully disperse and dissolve C60 in the solvent. After the ultrasonication, the above solution was taken out from the water bath, and filtered quickly to obtain a saturated solution of fullerene, which was purple in color and clear and transparent.

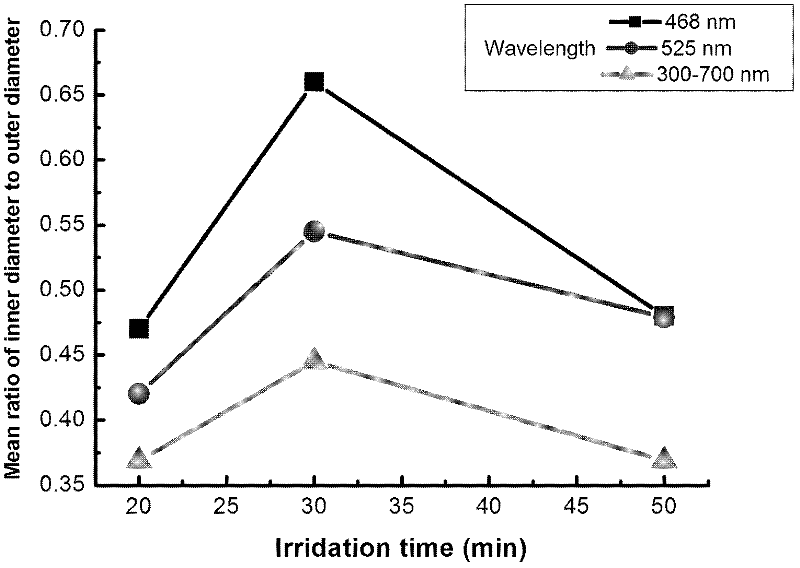

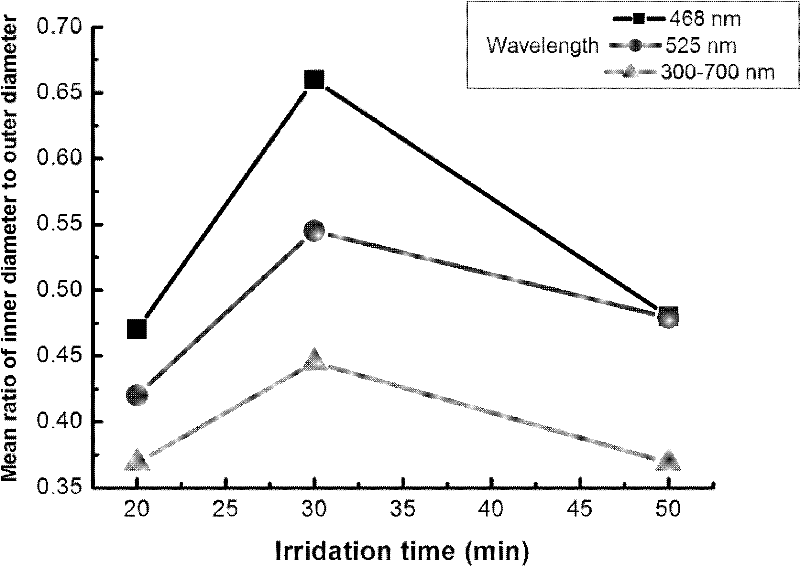

[0032] (2) Use an ice-water bath to control the temperature at 8° C., and irradiate the saturated solution of C60 with a blue LED light source with a center wavelength of 468 nm for 30 min. After irradiation, the solution was maroon and clear.

[0033] ...

Embodiment 2

[0035] A method for the controllable preparation of fullerene submicron tubes, comprising the following steps;

[0036] (1) Weigh 0.01g of C70 (purity > 99.5%) powder into a clean transparent glass bottle, measure 10ml of benzene in the glass bottle, mix it with the C70 powder, and seal the glass bottle. Put the above solution into an ultrasonic container, control the temperature of the water bath at 5°C with ice water, and ultrasonically sonicate with 50W power for 40min, so as to fully disperse and dissolve C70 in the solvent. After the ultrasonication, the above solution was taken out from the water bath, and filtered quickly to obtain a saturated solution of fullerene, which was purple in color and clear and transparent.

[0037] (2) Use an ice-water bath to control the temperature at 5° C., and irradiate the saturated solution of C70 with a green LED light source with a center wavelength of 525 nm for 30 min. After irradiation, the solution was maroon and clear.

[0038...

Embodiment 3

[0040] A method for the controllable preparation of fullerene submicron tubes, comprising the following steps;

[0041] (1) Weigh 0.01g of C60 / C70 (85 / 15) powder into a clean transparent glass bottle, measure 10ml of toluene and mix it with C60 / C70 powder in the glass bottle, and seal the glass bottle. Put the above solution into an ultrasonic container, use ice water to control the temperature of the water bath at 3°C, and use ultrasonic power of 70W for 50 minutes to fully disperse and dissolve C60 / C70 in the solvent. After the ultrasonication, the above solution was taken out from the water bath, and filtered quickly to obtain a saturated solution of fullerene, which was purple in color and clear and transparent.

[0042] (2) Use an ice-water bath to control the temperature at 3° C., and irradiate the saturated solution of C60 / C70 with a white LED light source with a central wavelength of 300-700 nm for 30 min. After irradiation, the solution was maroon and clear.

[0043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com