Method for preparing brominated butyl rubber

A technology of bromobutyl rubber and butyl rubber, which is applied in the field of its reaction process and device, solution halogenation method to prepare brominated butyl rubber, to achieve high mechanical properties, easy operation and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

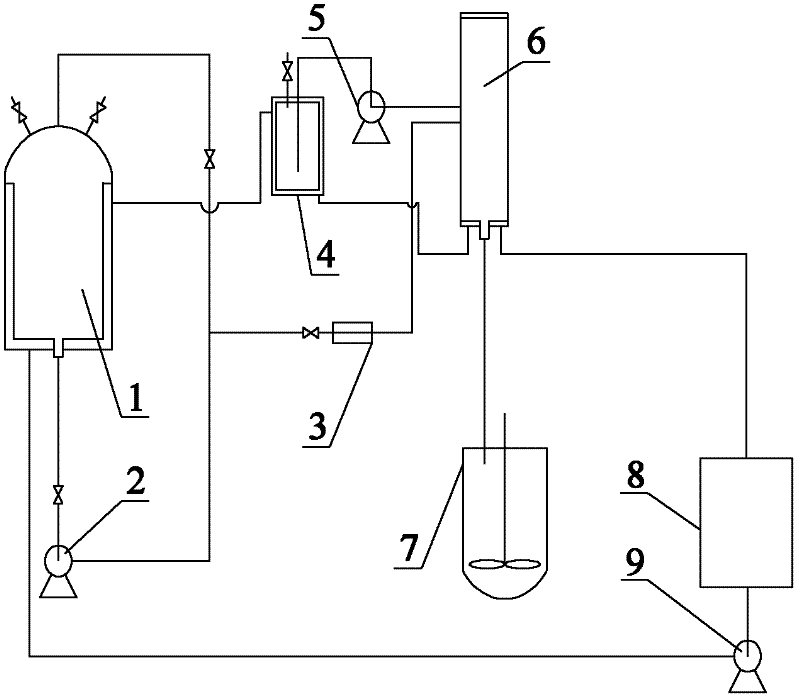

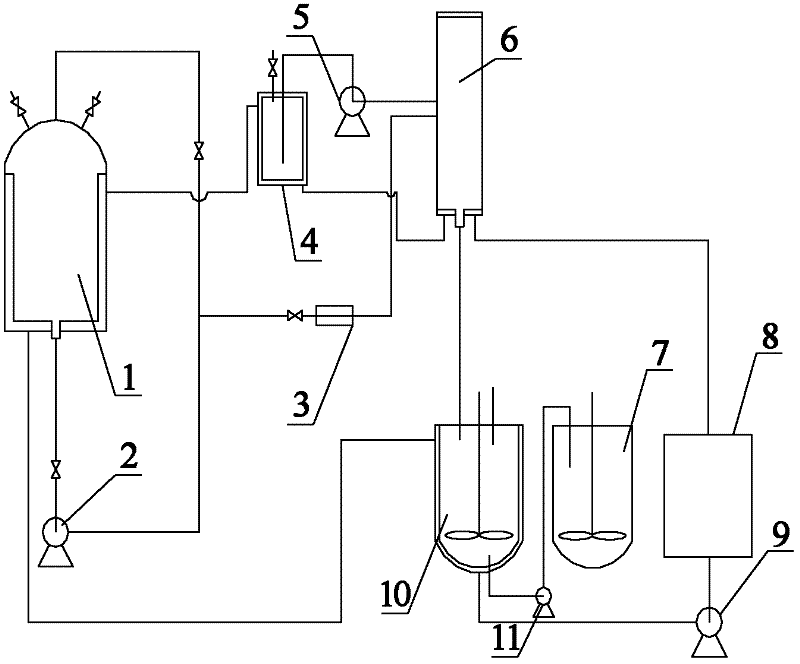

[0032] use figure 1 In the device shown, the reactor is a high-gravity rotating packed bed.

[0033] Add 8000ml of hexane solution A of butyl rubber into storage tank 1, the volume fraction of methylene chloride in solution A is 30%, the unsaturation of raw rubber is 1.82%, and the mass concentration of glue is 10%, add 29.15g 400ml of sodium hypochlorite aqueous solution per liter; 900ml of n-hexane solution B of liquid bromine is added in the storage tank 4, and the bromine elemental concentration is 31.2g / l; the materials in the storage tank 1 and the storage tank 4 are heated to 45°C respectively; And the volume flowmeter 3, the peristaltic pump 5 send the two streams of materials into the liquid premixing distributor of the supergravity reactor at a volume ratio of 10:1, and the mixed materials are sprayed into the rotor packing layer by the liquid distributor, and further mixed and Reaction; the material enters the stirred tank 7 through the liquid outlet of the rotatin...

Embodiment 2

[0035] The technological process and steps are the same as in Example 1, and the material ratio is also the same. The difference is that the concentration of the aqueous sodium hypochlorite solution used is 88.00g / l, the supergravity level is 20.12g, and the temperature is 30°C. The bromine content of the obtained bromobutyl rubber product is 1.91 (wt%), unsaturation 1.46%.

Embodiment 3

[0037] The technological process and steps are the same as in Example 1, and the material ratio is also the same, except that the supergravity level is 55.89g, the bromine content of the obtained bromobutyl rubber product is 1.93 (wt%), and the degree of unsaturation is 1.40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com