Method for preparing low-zinc vulcanized active agents by active carrier method

A vulcanization activator and modification technology, which is applied in the treatment of low-molecular organic compounds in dyeing, chemical instruments and methods, and the treatment of high-molecular organic compounds in dyeing. It can solve the problems of limited zinc ions, decreased application performance, and poor performance. The effect of outstanding price advantage, cost reduction and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

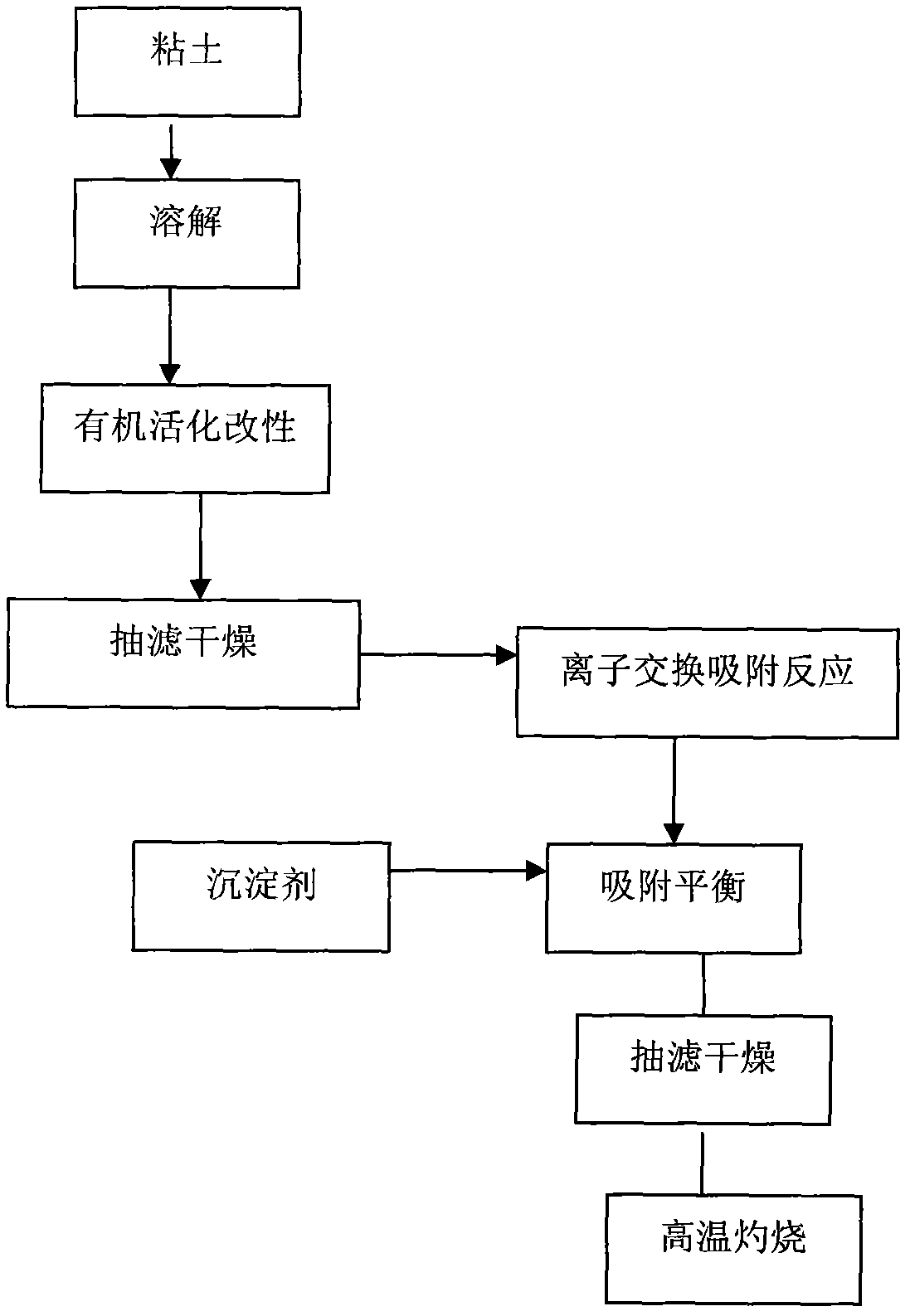

Method used

Image

Examples

Embodiment 1

[0044] Add sodium dodecylsulfonate with a mass concentration of 5% to the aqueous solution of montmorillonite at 20°C, stir for 2 hours, filter the fully modified montmorillonite with suction, wash with water until there is no sodium ion, and put it in 60°C Dry in oven for 12h.

[0045] Dissolve the modified montmorillonite in 1.5 mol / l zinc chloride salt solution, stir and react for 4 hours, then add 0.01 mol / l oxalic acid dropwise for 30 minutes. After fully stirring for 2 hours, the completely reacted montmorillonite was suction-filtered, washed until there was no chloride ion, and dried in an oven at 60°C for 24 hours.

[0046] The dried montmorillonite was fired at 450°C for 2h.

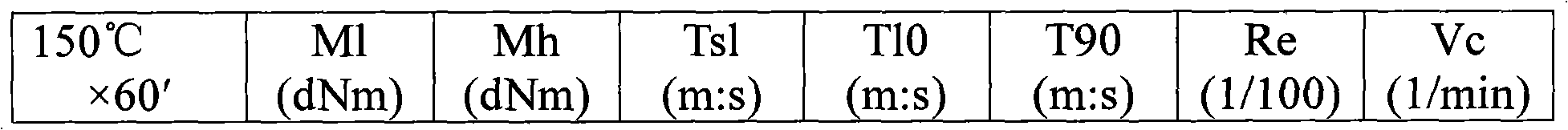

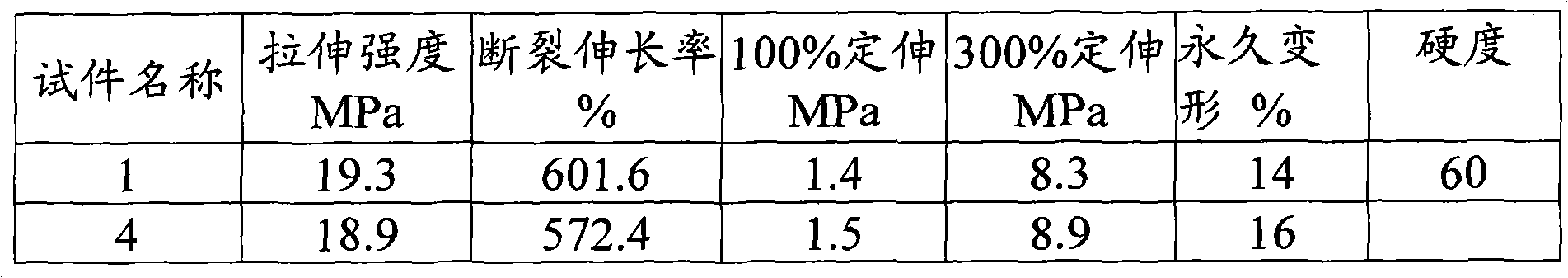

[0047] Evaluation test: The sample is subjected to the basic performance test in styrene-butadiene rubber 1712, using GB / T8656-1998, and the carbon black is N330.

[0048] The results of vulcanization instrument and strength test show that the low-zinc vulcanization activator sample and ordinary...

Embodiment 2

[0064] Add sodium dodecylbenzene sulfonate with a mass concentration of 5% to the kaolin aqueous solution at 40°C, and stir for 2 hours. Suction filter the fully modified kaolin, wash with water until there is no sodium ion, and put it in an oven at 80°C. Dry in medium for 12h.

[0065] The modified kaolin was dissolved in a 1.5 mol / l zinc sulfate solution, stirred and reacted for 4 hours, and then 0.1 mol / l hexamethylenetetramine was added dropwise for 30 minutes. After fully stirring for 2 hours, the fully reacted kaolin was suction-filtered, washed until no sulfate ions were present, and dried in an oven at 80°C for 24 hours.

[0066] The dried kaolin was burned at 250°C for 2h.

[0067] Evaluation test: The basic performance test of the sample is carried out in styrene-butadiene rubber 1502, using GB / T8656-1998, and the carbon black is N330.

[0068] The results of the vulcanization tester and the strength test show that the low-zinc vulcanization activator sample and or...

Embodiment 3

[0083] Add hexadecyltrimethylammonium bromide with a mass concentration of 2% to the vermiculite aqueous solution at 60°C, stir for 2 hours, filter the fully modified vermiculite with suction, wash with water until no ammonium ions are present, and put Dry in an oven at 80°C for 12 hours.

[0084] Dissolve the modified vermiculite in 1.0 mol / l zinc acetate solution, stir and react for 4 hours, then add 0.01 mol / l ammonia water dropwise for 30 minutes. After fully stirring for 4 hours, suction filter the completely reacted vermiculite, wash until there is no zinc ion, and put it into an oven at 80°C for 24 hours to dry.

[0085] Burn the dried vermiculite at 350°C for 2h.

[0086] Evaluation test: The basic performance test of the sample is carried out in the formula of butadiene rubber 9000, using GB / T8660-2008, and the carbon black is N330.

[0087] The results of the vulcanization tester and the strength test show that the low-zinc vulcanization activator sample and ordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com