Method for enhancing photosynthesis spectral intensity of LED phosphor by using plasma

A photosynthesis and spectral intensity technology, applied in ion implantation plating, chemical instruments and methods, luminescent materials, etc., can solve problems such as difficulty in large-scale application, influence on luminous efficiency, color mixing uniformity obstacles, etc. Conducive to popularization and application, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

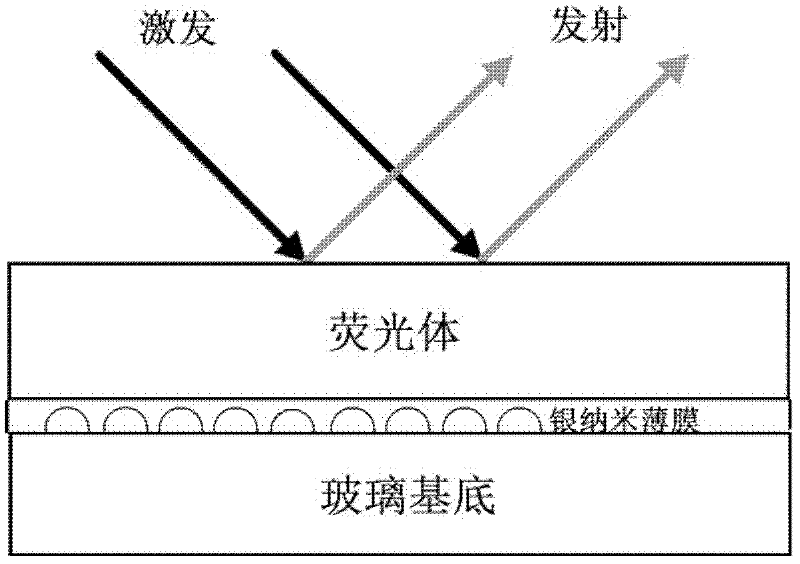

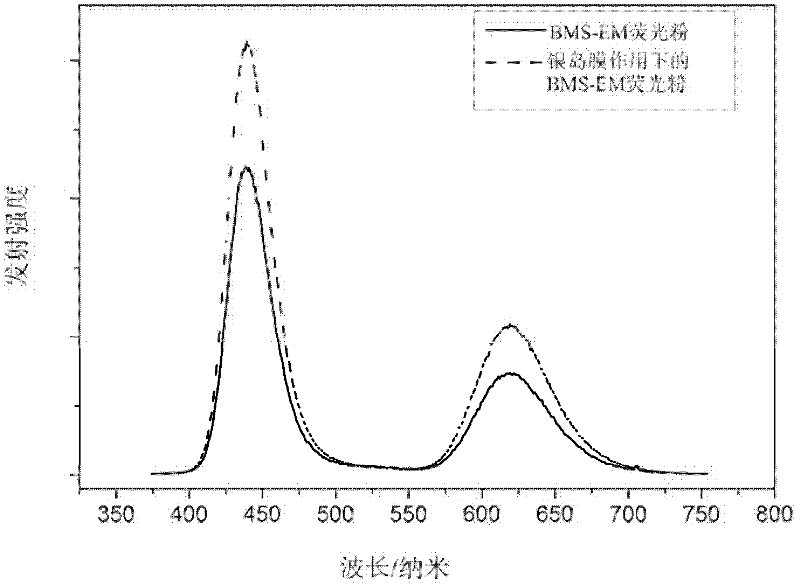

[0020] A method for increasing the photosynthetic spectral intensity of LED phosphors by using plasma, using the metal surface plasma effect to increase the photosynthetic spectral intensity of LED phosphors, the steps are as follows:

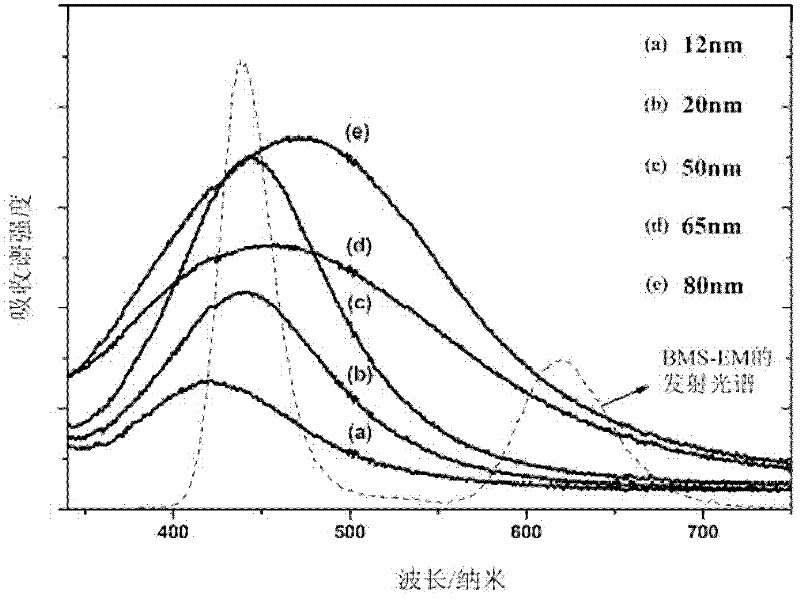

[0021] 1) Put the glass substrate into the sputtering chamber, and the air pressure in the chamber is pumped below 2Pa. At this time, argon gas is introduced as the protective gas, the air flow is 2.5l / min, the air pressure in the chamber is maintained at 2.8Pa, and the purity is 99.99%. The silver was sputtered as the target, and sputter deposition was performed. The sputtering current is 4mA, the sputtering time is selected as 40s, and the thickness of the silver film is 12nm. Afterwards, an island-shaped silver nanofilm is obtained after heat treatment in a nitrogen atmosphere with a purity of 99.99%. The heat treatment temperature is 200°C and the time is 21mins;

[0022] 2) put Ba 3 MgSi 2 o 8 :Eu 2+ , Mn 2+ Uniformly disperse in alco...

Embodiment 2

[0024] The steps are the same as in Example 1, except that the sputtering time is 60s, and the thickness of the silver film is 20nm.

Embodiment 3

[0026] The steps are the same as in Example 1, except that the sputtering time is 90s, and the thickness of the silver film is 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com