Method for preparing saccharide by decomposing cellulose through plasma electrolysis

A technology of plasma and cellulose, which is applied in the production of oligosaccharides or monosaccharides, can solve the problems of long process treatment process and large acid consumption, and achieve the effects of simplified production process, high sugar content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

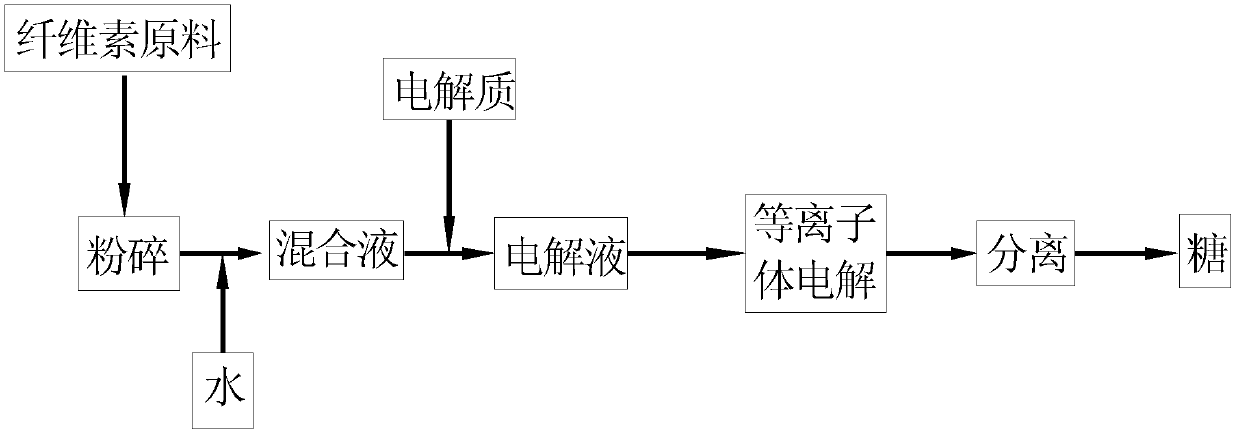

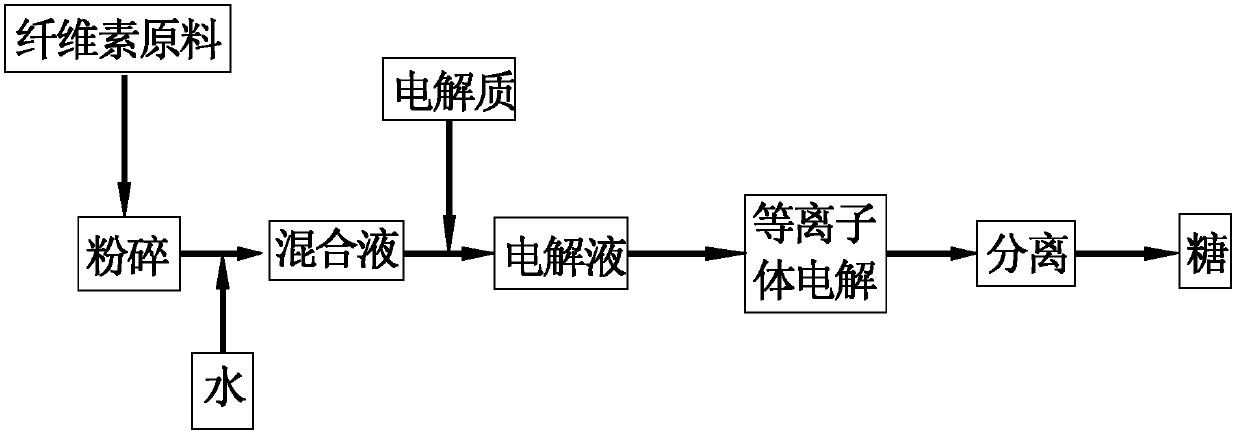

Method used

Image

Examples

Embodiment 1

[0023] The general electrolyzer is the plasma electrolysis reactor.

[0024] Step 1, using microcrystalline cellulose as a raw material, mixing microcrystalline cellulose and water in a mass ratio of 1:9 to form a mixed solution containing 10% cellulose;

[0025] Step 2. Add KOH solid to the above mixed solution to prepare a conductivity of 0.05S.m -1 Cellulose electrolyte;

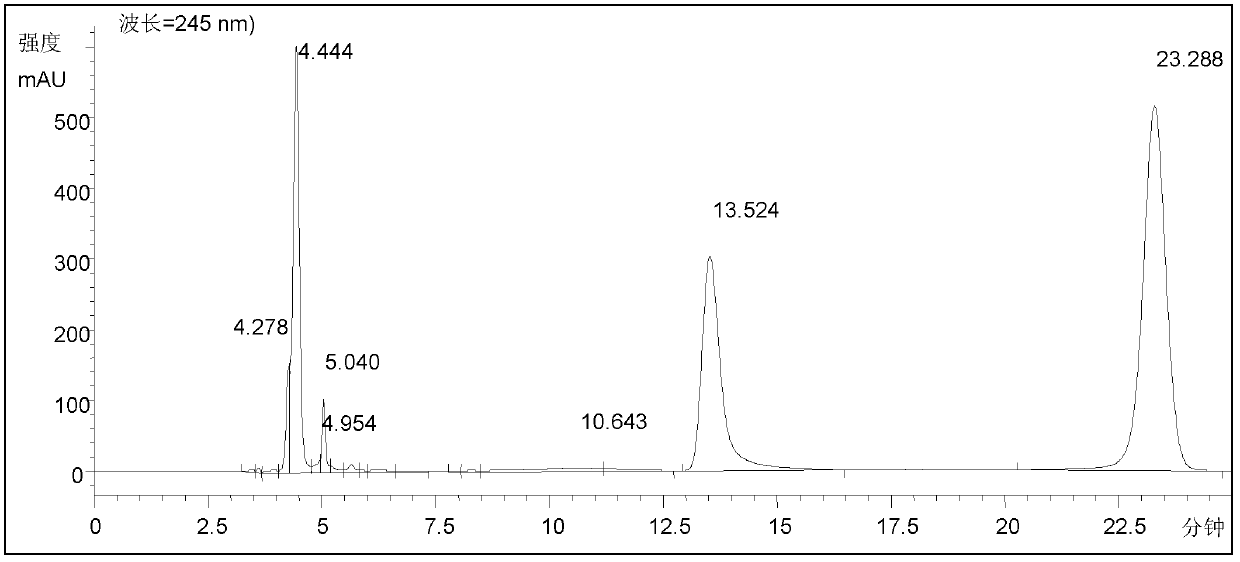

[0026] Step 3: Carry out cathodic plasma electrolysis on the above-mentioned cellulose electrolyte at a voltage of 800V, and treat for 1 hour. The high-energy particles generated during the electrolysis process and the strong oxidizing groups such as OH free radicals generated by the decomposition of water molecules act together on the cellulose On the glycosidic bond of the molecule, the cellulose is decomposed to obtain a solution containing 1.7% glucose, 0.2% mannose, 0.2% xylose and 0.8% arabinose, figure 2 It is the substance peak of 23.2 minutes that is the high-efficiency liquid phase chromatogr...

Embodiment 2

[0029] Step 1, using straw as raw material, crushing the straw into 150-mesh fine powder, and mixing it with water at a mass ratio of 1:4 to form a mixed solution containing 20% cellulose;

[0030] Step two, FeCl 2 The solid is added to the above mixed solution, and the conductivity is prepared to be 0.1S.m -1 Cellulose electrolyte;

[0031] Step 3: Perform anode plasma electrolysis on the above-mentioned cellulose electrolyte at a voltage of 700V, and treat for 2 hours. The high-energy particles generated during the electrolysis process and the strong oxidizing groups such as OH free radicals generated by the decomposition of water molecules act together on the cellulose On the glycosidic bond of the molecule, the cellulose is decomposed to obtain a solution containing 0.7% glucose, 0.02% mannose, 0.03% xylose and 0.3% arabinose;

[0032] Step 4, separating and purifying the above-mentioned sugar-containing solution to obtain relatively pure sugar.

Embodiment 3

[0034] Step 1, using straw as a raw material, crushing the straw into 100-mesh fine powder, and mixing it with water at a mass ratio of 1:4 to form a mixed solution containing 20% cellulose;

[0035] Step two, the H 2 SO 4 The solution is added to the above mixed solution, and the conductivity is prepared to be 0.05S.m -1 Cellulose electrolyte;

[0036] Step 3: Perform anode plasma electrolysis on the above-mentioned cellulose electrolyte at a voltage of 1000V, and treat for 2 hours. The high-energy particles generated during the electrolysis process and the strong oxidizing groups such as OH free radicals generated by the decomposition of water molecules act together on the cellulose On the glycosidic bond of the molecule, the cellulose is decomposed to obtain a solution containing 0.97% glucose, 0.012% mannose, 0.019% xylose and 0.41% arabinose;

[0037] Step 4, separating and purifying the above-mentioned sugar-containing solution to obtain relatively pure sugar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com