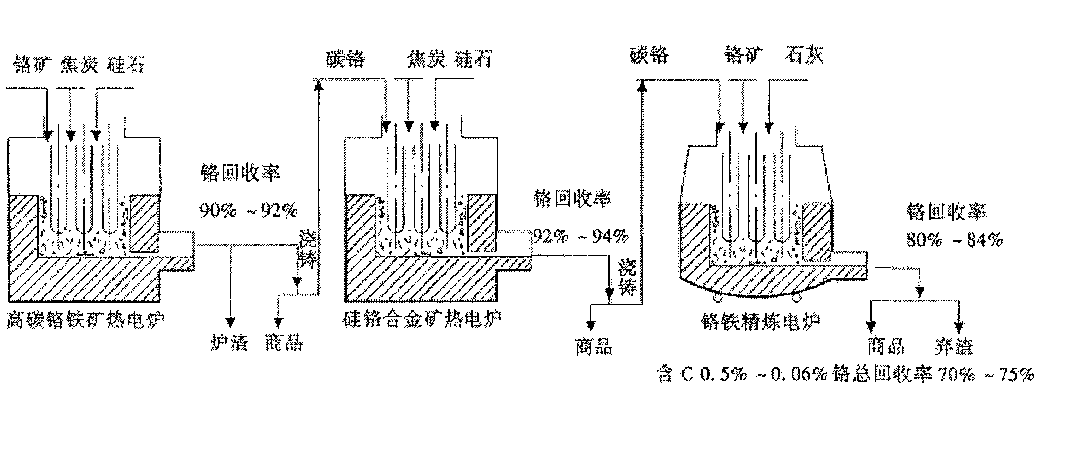

Argon oxygen refining low-carbon ferrochromium process endpoint carbon content and temperature control method

A technology for end-point carbon content and low-carbon ferrochromium, applied in the direction of process efficiency improvement, adaptive control, general control system, etc., can solve problems such as prolonging smelting time, inability to continuously detect carbon content online, and reducing furnace age.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

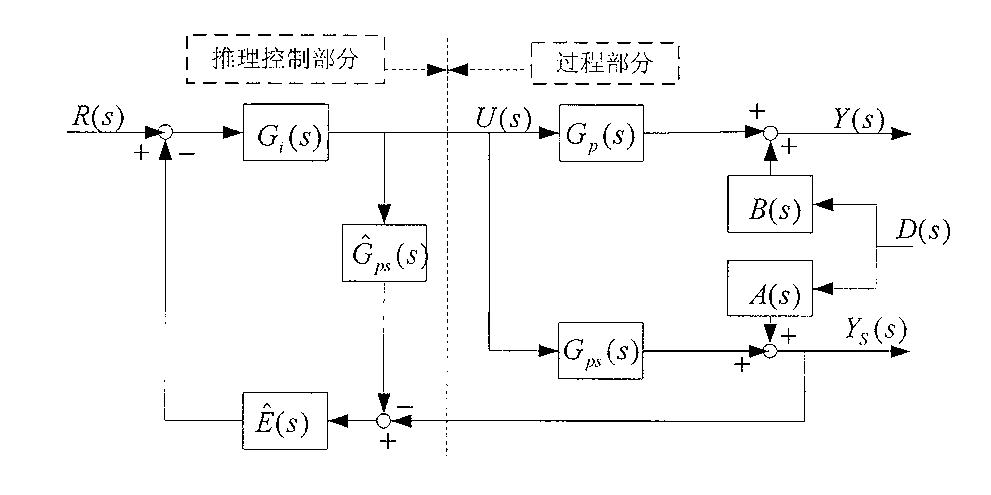

[0025] The method of the present invention is:

[0026] 1. Pour the molten iron roughly smelted in the electric furnace into the AOD furnace, and blow oxygen from the top lance for rapid decarburization. When the carbon content drops to a critical value, the bottom lance starts to blow the mixed gas of oxygen and argon for decarburization reaction, and finally Then blow with pure Ar gas for a few minutes, so that the residual oxygen in the molten iron continues to react with carbon to further reduce the carbon content. When the carbon content reaches the predetermined target, add ferrosilicon under Ar gas stirring for reduction;

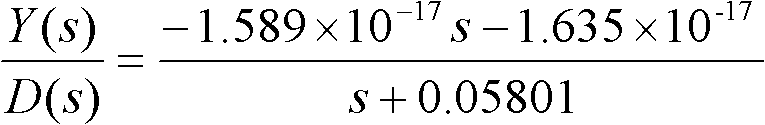

[0027] 2. Indirectly control the carbon content of the molten iron by controlling the temperature of the molten iron, so that the temperature and carbon content of the molten iron can be controlled more precisely at each point in the refining process, especially the precise control of the end point temperature and carbon content of the molten iron. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com