Capacitive single-mass block full comb electrode sensor for triaxial acceleration and manufacturing method thereof

A shaft acceleration, comb electrode technology, applied in the measurement of acceleration, multi-dimensional acceleration measurement, piezoelectric devices/electrostrictive devices and other directions, can solve the problems of increasing process difficulty, complex processing technology, large device volume, etc. Difficulty, Guaranteed Sensitivity, High Sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

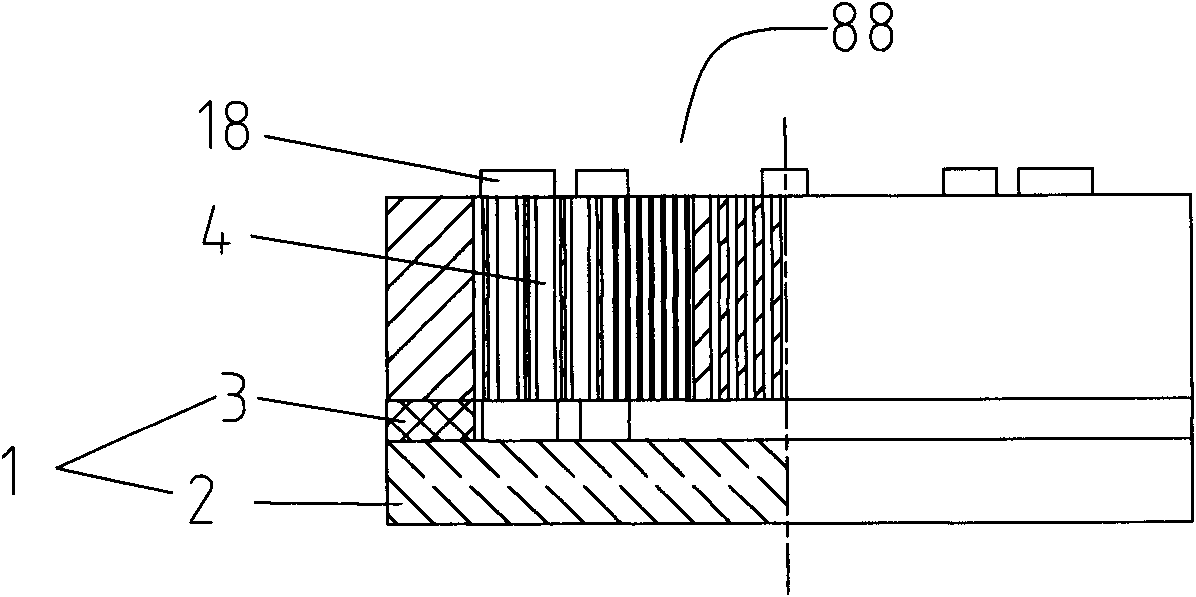

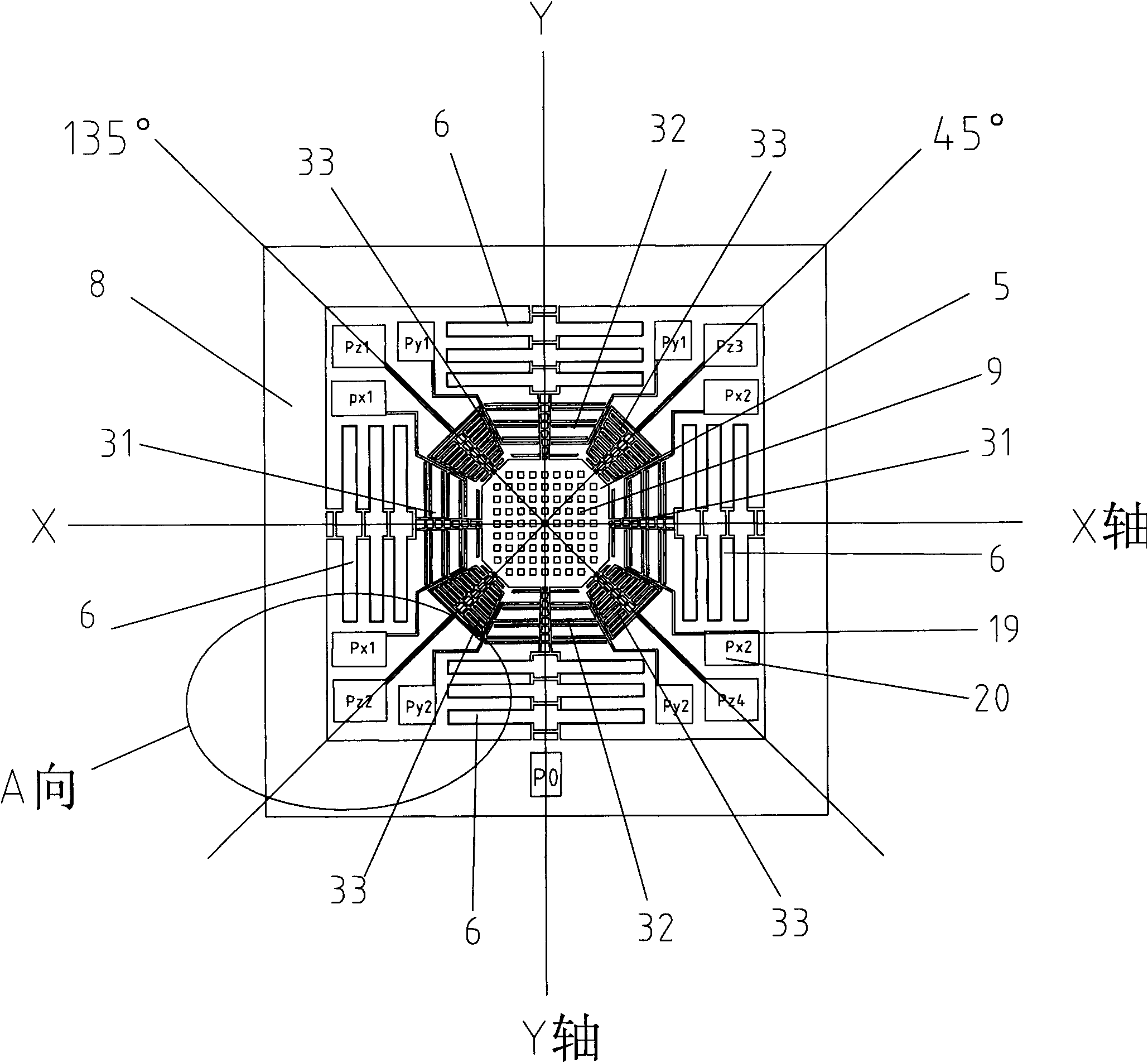

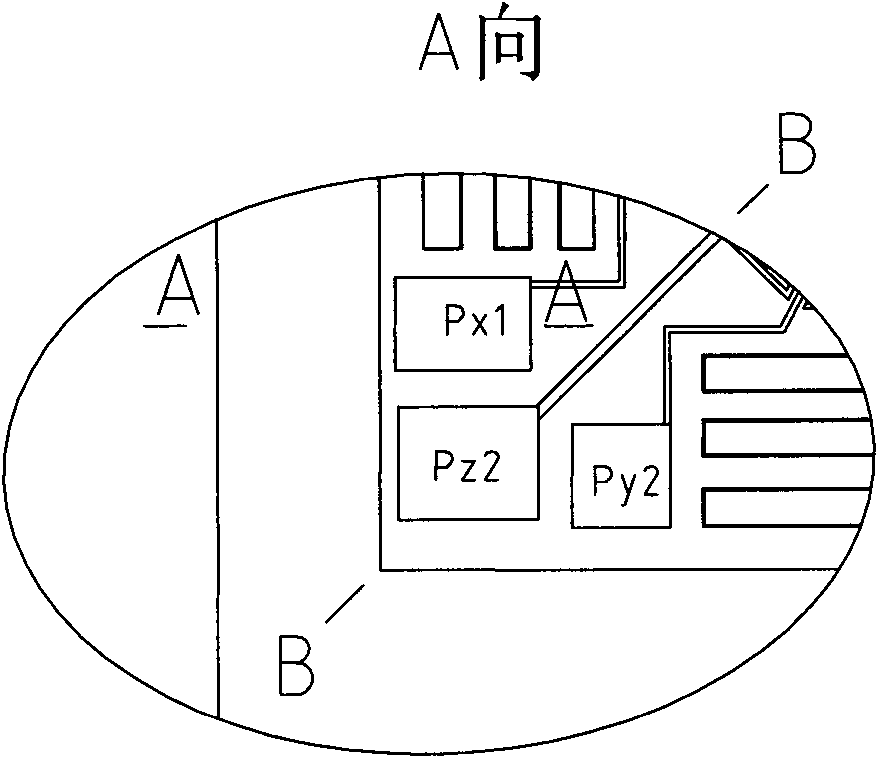

[0049] Such as Figure 1A to Figure 1G-2 A capacitive single-mass full-comb electrode three-axis acceleration sensor is shown, which includes a substrate 1, an induction mechanism 4 and a signal output mechanism 18, and the substrate 1 includes a substrate 2 and a dielectric insulating layer deposited on the substrate 3. The material of the substrate 2 is single crystal silicon, the material of the dielectric insulating layer 3 is silicon oxide or silicon nitride, and a peripheral support 8 and a plurality of fixed supports 36 are fixed vertically on the base 1, wherein the peripheral support 8 is located on the base 1 above the outer edge;

[0050] The induction mechanism 4 includes a mass block 5, a comb structure and a spring mechanism 6, and the mass block 5, the comb structure and the spring mechanism 6 are distributed from the center of the base to the periphery, the mass block 5 and the comb structure are located in the same plane, and the mass The block 5 is a single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com