Environmental-friendly calcium-zinc stabilizer for PVC (Polyvinyl Chloride) rolling film and preparation method thereof

A calcium-zinc stabilizer and calendering film technology, applied in the field of chemical stabilizers, can solve the problems of poor heat resistance, poor weather resistance, and easy deformation, and achieve simple preparation methods, good weather resistance, and good heat stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

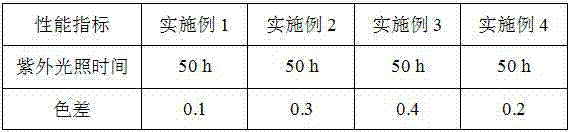

Examples

Embodiment 1

[0065] First take 20Kg magnesium-aluminum binary hydrotalcite (MgO / AL in magnesium-aluminum binary hydrotalcite 2 o 3 The molar ratio is 4.0:1) and 20Kg zinc-magnesium-aluminum ternary hydrotalcite (ZnO / MgO / AL in zinc-magnesium-aluminum ternary hydrotalcite 2 o 3 The molar ratio is 2:4:2) into the high-speed mixer, the speed of the high-speed mixer is 1000 r / min, stirring at 55 ° C for 5 min; then continue to add 5Kg calcium stearate, 10Kg calcium benzoate, 5Kg stearin Zinc acid zinc, 10Kg zinc benzoate, 10Kg butyl stearate and 10Kg 2-acetyl-3-methylthiophene were stirred for 10 min under the conditions of a rotation speed of 1000 r / min and a temperature of 55°C; finally, 5Kg of β -(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 2Kg dibenzoylmethane, 1Kg ethyl acetoacetate and 2Kg ultraviolet absorber UV-9, in which high-speed mixer The rotating speed is 1000 r / min, stirred at 55°C for 15 min, and after cooling, an environmentally friendly calcium-zinc stabilize...

Embodiment 2

[0067] First take 10Kg magnesium-aluminum binary hydrotalcite (MgO / AL in magnesium-aluminum binary hydrotalcite 2 o 3 The molar ratio is 4.5:1) and 20Kg zinc-magnesium-aluminum ternary hydrotalcite (ZnO / MgO / AL in zinc-magnesium-aluminum ternary hydrotalcite 2 o 3 The molar ratio is 4:2:2) into the high-speed mixer, the speed of the high-speed mixer is 1250 r / min, and stirred at 60°C for 10 min; then continue to add 15Kg calcium benzoate, 5Kg pentacarbon fatty acid calcium, 5Kg laurel zinc benzoate, 10Kg zinc benzoate, 5Kg butyl monostearate, 10Kg liquid paraffin and 5Kg α-chloromethylthiophene, stirred for 10 min under the conditions of 1250 r / min and 60°C; 5Kg of tris[2.4-di-tert-butylphenyl]phosphite, 2Kg of stearoylbenzoylmethane, 3Kg of dehydroacetic acid and 5Kg of ultraviolet absorber UV-327, wherein the speed of the high-speed mixer is 1250 r / min, Stir at 60°C for 10 min, and after cooling, an environmentally friendly calcium-zinc stabilizer for PVC calendering film ...

Embodiment 3

[0069] First take 10Kg magnesium-aluminum binary hydrotalcite (MgO / AL in magnesium-aluminum binary hydrotalcite 2 o 3 The molar ratio is 4.2:1) and 20Kg zinc-magnesium-aluminum ternary hydrotalcite (ZnO / MgO / AL in zinc-magnesium-aluminum ternary hydrotalcite 2 o 3 The molar ratio is 3:3:2) into the high-speed mixer, the speed of the high-speed mixer is 1500 r / min, stirring at 65 ° C for 5 min; then continue to add 5Kg heptadecanoic acid calcium, 10Kg dodecylbenzene Calcium acid calcium, 5Kg zinc dodecylbenzenesulfonate, 15Kg zinc stearate, 5Kg glyceryl monostearate, 5Kg paraffin wax and 15Kg α-chlorothiophene, at a speed of 1500 r / min and a temperature of 65°C Stirring under the condition of 5 min; finally add 3Kg tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 1Kg acetylacetone, 1Kg 2,3-pentanedione, 2Kg ultraviolet absorber UV-P and 3Kg ultraviolet absorber UV-320, wherein the speed of the high-speed mixer is 1500 r / min, stirred at 65°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com