Process for producing methanol-to-hydrocarbon-based fuel (MTHF)

A technology of hydrocarbon-based fuel and production process, which is applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve problems such as complex preparation process, and achieve the effect of promoting mutual solubility of alcohol and oil and improving product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

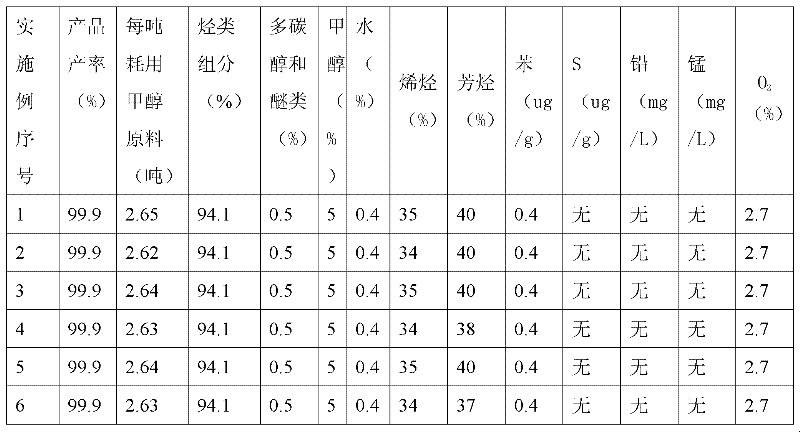

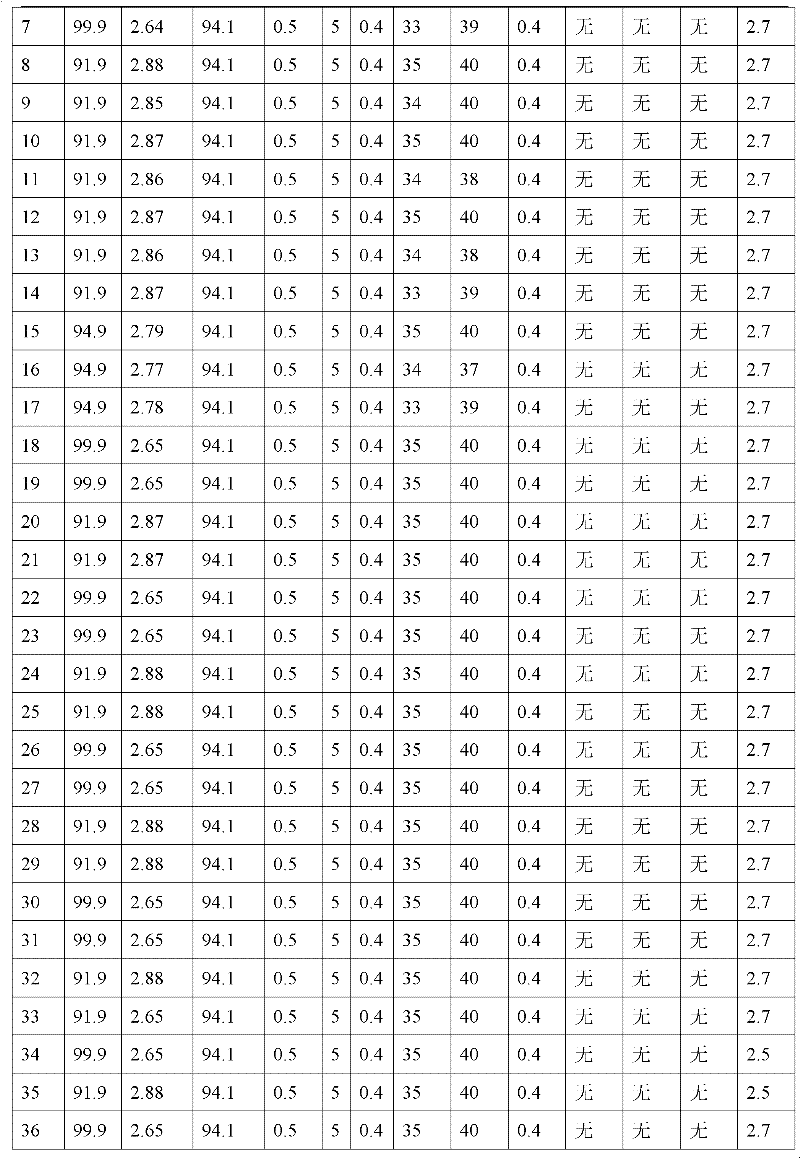

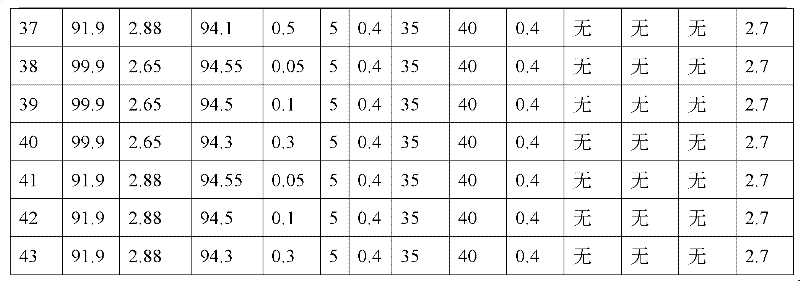

Examples

Embodiment 1

[0056] Step (1) methanol gasification

[0057] Using refined methanol that meets the GB338 standard as the raw material, the raw methanol is boosted to 0.83MPa, then enters the preheater to preheat to 85°C, and then enters the gasification tower for gasification. The temperature of the obtained gaseous methanol is 126°C and the pressure is 0.80MPa.

[0058] The preparation of step (2) dimethyl ether

[0059] The gasified methanol obtained in step (1) is heated to 270°C through the inlet and outlet heat exchangers of the dimethyl ether reactor, and then it enters the top of the catalyst bed in the dimethyl ether reactor, from top to bottom The dehydration condensation reaction is carried out by setting three chilled catalyst beds. The catalyst used in the reaction is the CNM-3 catalyst developed by the Southwest Chemical Industry Research Institute and has been commercially produced. The reaction pressure is 0.8MPa, the hot spot temperature is 380°C, and the Speed is 2.0h ...

Embodiment 2

[0073] Step (1) gasification of methanol, step (3) preparation of hydrocarbon components, step (4) cooling of hydrocarbonated products, and step (5) product separation are the same as in Example 1.

[0074] In the preparation of step (2) dimethyl ether, the vaporized methanol obtained in step (1) is heated to 250°C through the inlet and outlet heat exchangers of the dimethyl ether reactor, and then it enters the dimethyl ether reaction The top of the catalyst bed in the vessel passes through the three chilled catalyst beds from top to bottom to carry out the dehydration condensation reaction. The catalyst used in the reaction is the CNM-3 catalyst developed by the Southwest Chemical Industry Research Institute and has been commercially produced. The pressure is 0.7MPa, the hot spot temperature is 360°C, and the space velocity is 1.5h -1 , to obtain a reaction product mainly composed of dimethyl ether, which flows out from the bottom of the catalyst bed.

[0075] The above ste...

Embodiment 3

[0078] Step (1) gasification of methanol, step (3) preparation of hydrocarbon components, step (4) cooling of hydrocarbonated products, and step (5) product separation are the same as in Example 1.

[0079] In the preparation of step (2) dimethyl ether, the vaporized methanol obtained in step (1) is heated to 260°C through the inlet and outlet heat exchangers of the dimethyl ether reactor, and then it enters the dimethyl ether reaction The top of the catalyst bed in the vessel passes through the three chilled catalyst beds from top to bottom to carry out the dehydration condensation reaction. The catalyst used in the reaction is the CNM-3 catalyst developed by the Southwest Chemical Industry Research Institute and has been commercially produced. The pressure is 0.75MPa, the hot spot temperature is 370℃, and the space velocity is 1.75h -1 , to obtain a reaction product mainly composed of dimethyl ether, which flows out from the bottom of the catalyst bed.

[0080] The above st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com