Method for manufacturing chip type organic solid electrolyte electrolytic capacitor

A technology of electrolytic capacitors and organic solids, applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of poor voltage withstand capacity of capacitors, deteriorated dielectric film withstand voltage performance, and unable to increase the rated working voltage of capacitors, etc., to achieve good control , Improve the effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

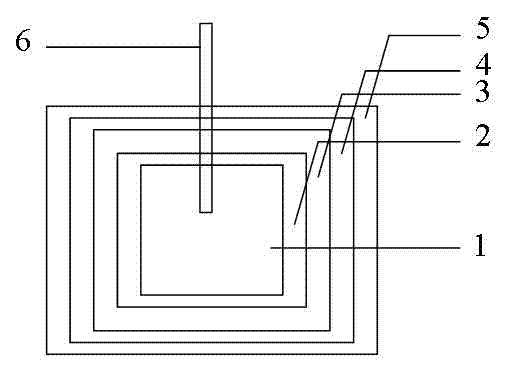

[0043] Press the tantalum powder into a tantalum block according to a certain pressing density, and sinter the obtained tantalum block in a vacuum sintering furnace to obtain a tantalum block core with a certain strength. At this time, the state of the tantalum block core is a sponge-like sintered porous state; then The sintered tantalum block is formed into Ta in acidic aqueous solution 2 o 5 Dielectric oxide film, the oxide film is used as the dielectric layer of the organic chip electrolytic capacitor; the tantalum block core formed with the dielectric oxide film is alternately dipped in the polycation solution and the polyanion solution for several times to obtain a certain thickness of conductive polymer The composite polyelectrolyte is used as the cathode of the chip electrolytic capacitor; finally, the capacitor core coated with the cathode is impregnated with graphite and silver paste respectively to obtain a chip organic solid electrolyte tantalum electrolytic capacit...

Embodiment 2

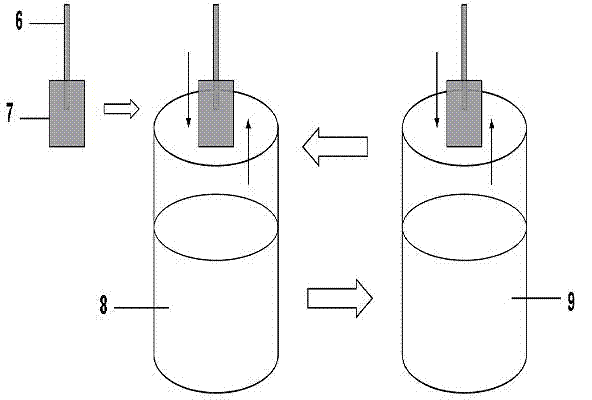

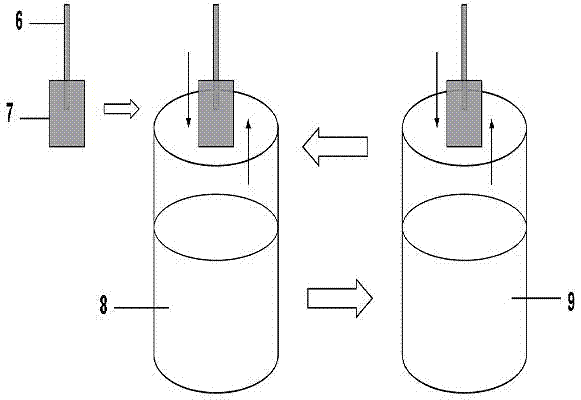

[0056] Such as figure 1 As shown, the manufacturing process of the capacitor is similar to Embodiment 1, and the formation voltage of ③ in the embodiment is changed to 38V.

[0057] The basic parameters of the obtained chip type organic solid electrolyte tantalum electrolytic capacitor are: rated voltage: 10V; capacity: 337μF; equivalent series resistance: 40mΩ; leakage current (measured at 12V): 26μA.

Embodiment 3

[0059] Such as figure 1 As shown, the manufacturing process of the capacitor is similar to Embodiment 1, the number of ⑤ cycles in the embodiment is 7 times, and the number of ⑥ cycles in the embodiment is 6 times.

[0060] The basic parameters of the obtained chip organic solid electrolyte tantalum electrolytic capacitor are: rated voltage: 10V; capacity: 468μF; equivalent series resistance: 55mΩ; leakage current (measured at 12V): 12μA. Due to the adjustment of the thickness of the cathode film, the equivalent series resistance of the capacitor becomes larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com