Preparation method of lithium ion battery cathode material of lithium manganese silicate

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory electrochemical cycle performance and large energy loss of materials, and achieve shortened synthesis cycle, uniform mixing, and small particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

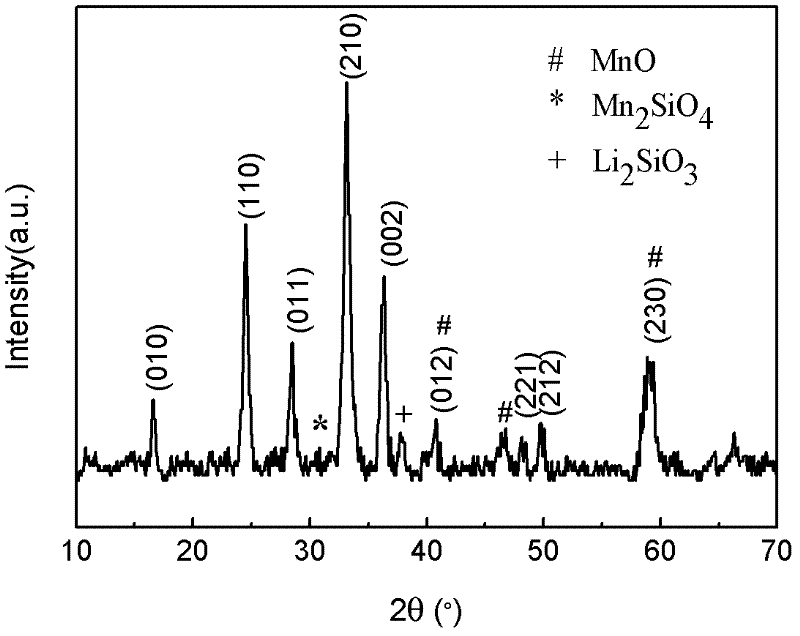

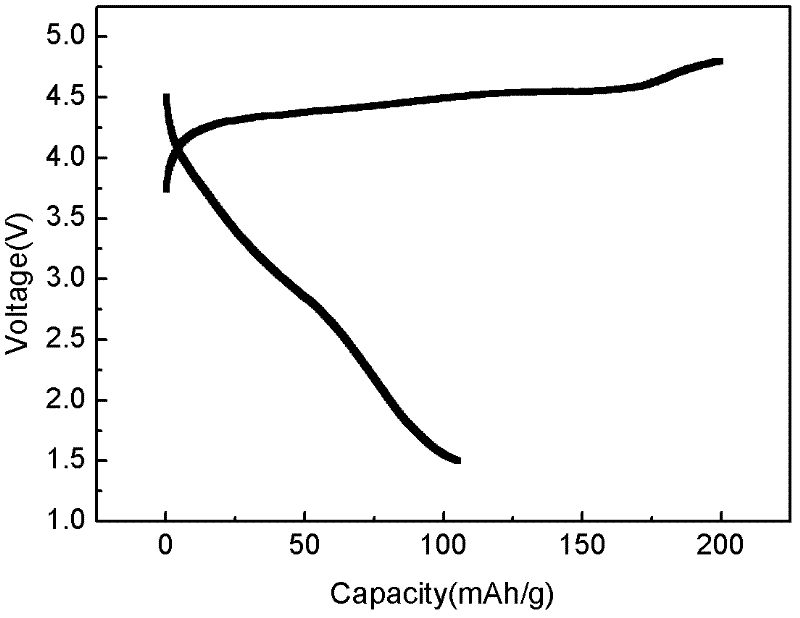

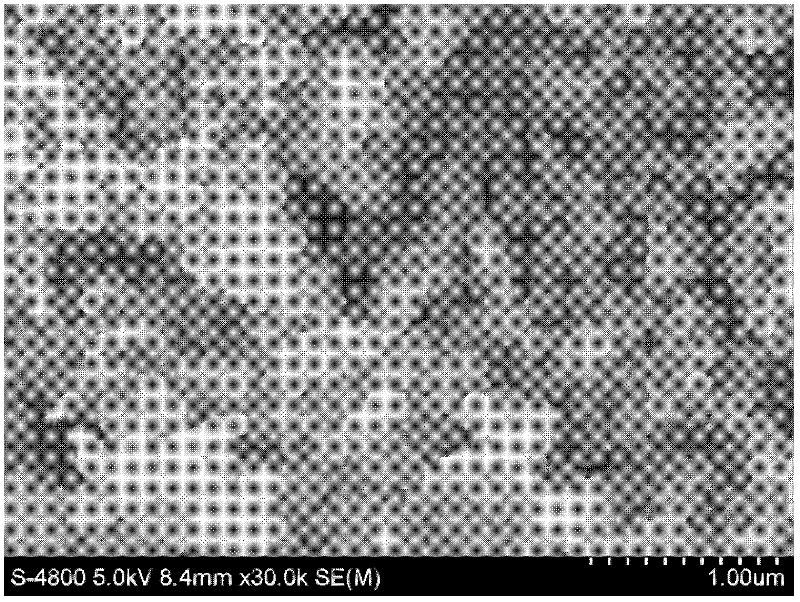

[0025] 0.02mol of SiO 2 The aerogel was dissolved in 100ml deionized water, and was ultrasonicated for 50 minutes at a power of 180W before use. At the same time, weigh 0.04mol of CH 3 COOLi·2H 2 O (99%) and 0.02mol of Mn (CH 3 COO) 2 4H 2 O (99%) was dissolved in 100 ml of distilled water. At room temperature, SiO after sonication 2 The solution was slowly added dropwise to the above solution, and ultrasonicated at 80W for 25min. Afterwards, under the condition of constant stirring, 100ml solution prepared by 0.02mol citric acid and 0.04mol ethylene glycol was slowly added into the above 200ml mixed solution. After mixing evenly, the pH was adjusted to 5 with ammonia water, and the resulting solution was placed in a water bath at 80° C., and stirred continuously until a colloid was formed. Dry the obtained gel in a vacuum drying oven at 120°C for 12 minutes to obtain a dry gel. After being fully ground, place it at 350°C and fill it with N 2 Sintering in a tube furna...

Embodiment 2

[0027] 0.01mol of SiO 2 The aerogel was dissolved in 100ml deionized water, and was ultrasonicated for 60 minutes at a power of 190W before use. At the same time, weigh 0.02mol of CH 3 COOLi·2H 2 O (99%) and 0.01mol of Mn (CH 3 COO) 2 4H 2 O (99%) was dissolved in 100 ml of distilled water. At room temperature, SiO after sonication 2 The solution was slowly added dropwise to the above solution, and ultrasonicated at 90W for 25min. Afterwards, under the condition of constant stirring, 100ml solution prepared by 0.01mol citric acid and 0.02mol ethylene glycol was slowly added into the above 200ml mixed solution. After mixing evenly, the pH was adjusted to 6 with ammonia water, and the obtained solution was placed in a water bath at 80° C., and stirred continuously until a colloid was formed. The obtained gel was dried in a vacuum oven at 120°C for 12 hours to obtain a dry gel, which was fully ground and then placed at 350°C and filled with N 2 Sintering in a tube furnac...

Embodiment 3

[0029] 0.015mol of SiO 2 The aerogel was dissolved in 100ml of deionized water, and was ultrasonicated for 70min under the power of 200W for use. At the same time, weigh 0.03mol of CH 3 COOLi·2H 2 O (99%) and 0.015mol of Mn (CH 3 COO) 2 4H 2 O (99%) was dissolved in 100 ml of distilled water. At room temperature, SiO after sonication 2 The solution was slowly added dropwise to the above solution, and ultrasonicated at 90W for 30min. Afterwards, under the condition of constant stirring, 100ml solution prepared by 0.015mol citric acid and 0.03mol ethylene glycol was slowly added to the above 200ml mixed solution. After mixing evenly, the pH was adjusted to 7 with ammonia water, and the resulting solution was placed in a water bath at 80° C. and kept stirring until a colloid was formed. The obtained gel was dried in a vacuum oven at 120°C for 12 hours to obtain a dry gel, which was fully ground and then placed at 350°C and filled with N 2 Sintering in a tube furnace in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com