Temporary fixing sheet

A temporary fixation, specific temperature technology, applied in the direction of electrical solid devices, thermally activated films/sheets, film/sheet adhesives, etc., can solve the problem of chip re-attachment and other problems, achieve good handling and reduce re-attachment , the effect of excellent productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

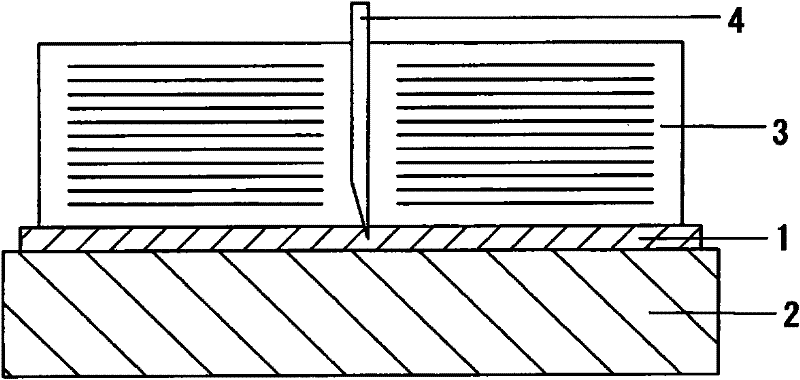

Image

Examples

Embodiment 1

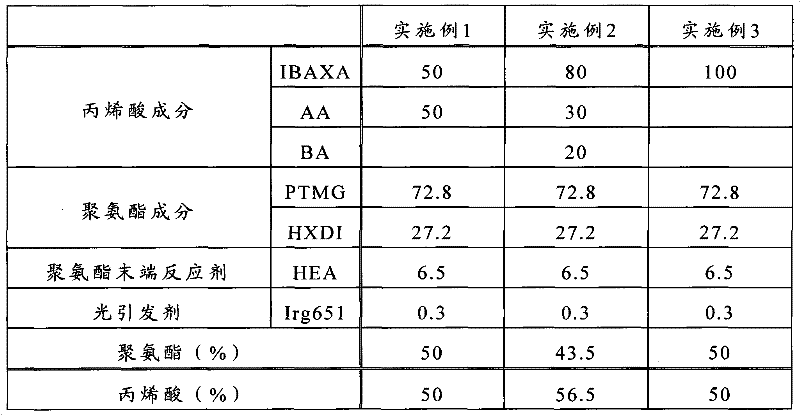

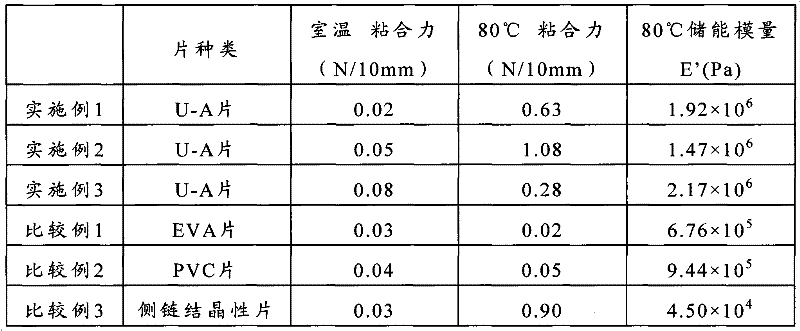

[0097] 50 parts by weight of isobornyl acrylate (IBXA) as a (meth)acrylic monomer and 72.8 parts by weight of polyol with a number average molecular weight of 650 (Tetramethylene) diol (manufactured by PTMG, Mitsubishi Chemical Corporation), dropwise added 27.2 parts by weight of hydrogenated xylylene diisocyanate (manufactured by HXDI, manufactured by Mitsui Chemicals Polyurethane Co., Ltd.) while stirring, and made it After reacting for 10 hours, a polyurethane polymer-acrylic monomer mixture was obtained. Thereafter, 6.5 parts by weight of 2-hydroxyethyl acrylate (HEA) was added dropwise and allowed to react for 3 hours, and then, 50 parts by weight of acrylic acid (AA) and 0.3 parts by weight of 2,2-dimethyl Oxy-1,2-diphenylethan-1-one (IRGACURE 651, manufactured by Ciba Japan K.K.). In addition, the usage-amount of a polyisocyanate component and a polyol component is NCO / OH (equivalent ratio)=1.25.

[0098] A mixture of polyurethane polymer and acrylic monomer was coate...

Embodiment 2

[0100] 80 parts by weight of isobornyl acrylate (IBXA) as a (meth)acrylic monomer, 20 parts by weight of butyl acrylate (BA), and 72.8 parts by weight of poly(tetramethylene) glycol (manufactured by PTMG and Mitsubishi Chemical Corporation) with a number average molecular weight of 650, 27.2 parts by weight of HXDI was added dropwise while stirring, and it was reacted for 10 hours at 65° C. to obtain polyurethane polymer compound - a mixture of acrylic monomers. Then, 6.5 parts by weight of 2-hydroxyethyl acrylate (HEA) was added dropwise and reacted for 3 hours, and then, 30 parts by weight of acrylic acid (AA) and 0.3 parts by weight of IRGACURE 651 as a photopolymerization initiator were added. In addition, the usage-amount of a polyisocyanate component and a polyol component is NCO / OH (equivalent ratio)=1.25.

[0101] A mixture of polyurethane polymer and acrylic monomer was coated onto release-treated PET with a thickness of 38 μm so that the thickness after curing was 1...

Embodiment 3

[0103] 100 parts by weight of isobornyl acrylate (IBXA) as a (meth)acrylic monomer, 72.8 parts by weight of poly( Tetramethylene) diol (PTMG, manufactured by Mitsubishi Chemical Corporation) was added dropwise with stirring, and 27.2 parts by weight of HXDI was reacted at 65° C. for 10 hours to obtain a polyurethane polymer-acrylic monomer mixture. Then, 6.5 parts by weight of 2-hydroxyethyl acrylate (HEA) was added dropwise and reacted for 3 hours, and then, 0.3 parts by weight of IRGACURE 651 was added as a photopolymerization initiator. In addition, the usage-amount of a polyisocyanate component and a polyol component is NCO / OH (equivalent ratio)=1.25.

[0104] A mixture of polyurethane polymer and acrylic monomer was coated onto release-treated PET with a thickness of 38 μm so that the thickness after curing was 100 μm. Overlap the peeled PET film on it, and then use a black light lamp to irradiate ultraviolet rays (illuminance 5mW / cm2) to the coated PET film surface. 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com