Hall element of two-dimensional electronic gas structure and manufacturing method thereof

A two-dimensional electron gas and Hall element technology, which is applied in the manufacture/processing of Hall effect devices, parts of electromagnetic equipment, and electromagnetic devices, can solve the problem of failure to work normally, low sensitivity, and failure to work at high temperatures and other issues to achieve the optimal effect of area utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

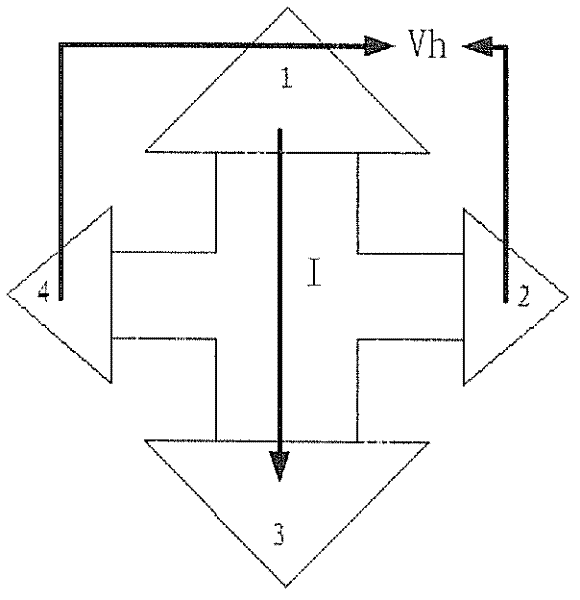

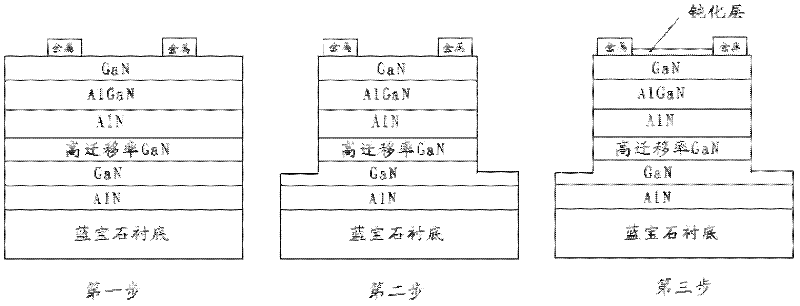

[0029] based on figure 2 As shown in the Hall element of the two-dimensional electron gas structure, the present invention also provides a preparation method of the Hall element of the two-dimensional electron gas structure, the method comprising: making an ohmic contact metal on the epitaxial material structure; performing mesa etching on the epitaxial material structure of the ohmic contact metal; and performing surface passivation on the epitaxial material structure performing mesa etching. The specific preparation process is as image 3 shown.

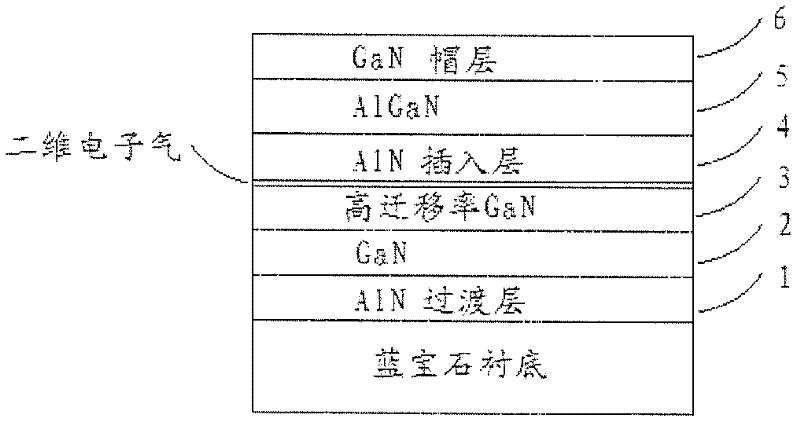

[0030] exist image 3In the step of making ohmic contact metal (i.e. the first step), the epitaxial material structure is a two-dimensional electron gas multilayer composite structure grown on a sapphire substrate, and the two-dimensional electron gas multilayer composite structure is included in The AlN transition layer, GaN layer, high-mobility GaN layer, AlN insertion layer, AlGaN layer and GaN cap layer grown sequentially o...

Embodiment

[0036] 1) Epitaxial growth of GaN / AlN / AlGaN two-dimensional electron gas Hall element materials.

[0037] Epitaxial material growth uses the method of MOCVD (Metal Organic Chemical Vapor Deposition). First, the first epitaxial layer on the sapphire substrate is an AlN transition layer with a thickness of 100nm; then grow GaN and high-mobility GaN layers with a thickness of 2μm and 100nm respectively, and grow the fourth layer as an AlN transition layer with a thickness of 0.7nm, followed by The fifth layer of growth is AlGaN with a thickness of 22nm, and the sixth layer is a GaN cap layer with a thickness of 2nm. At this point, the growth of the material is over.

[0038] 2) Preparation process of GaN / AlN / AlGaN two-dimensional electron gas Hall element.

[0039] In the first step, make the ohmic contact metal. The substrate was subjected to standard cleaning, and then dried in a 120-degree oven for 10 minutes. Using inversion photoresist AZ5214E, ohmic contact metal was fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com