Anti-bacterial peptide hydrolysate of earthworm and feed comprising the same

A peptide hydrolyzate and earthworm technology, applied in the field of earthworm antibacterial peptide hydrolyzate, can solve the problems of reducing antibacterial peptide antibacterial activity, digestive enzyme activity, complicated production process, and affecting the use effect, so as to achieve improved disease resistance, simple production process, Effect of Feed-to-Meat Ratio Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

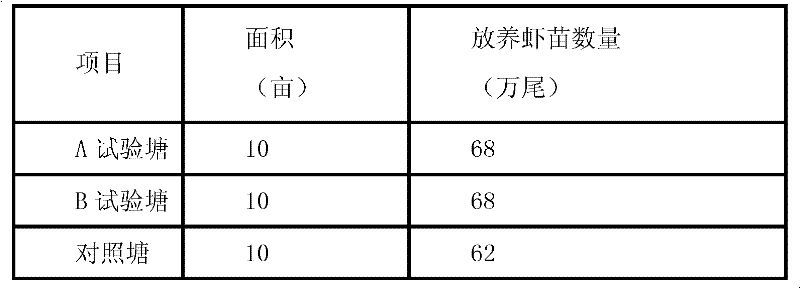

Image

Examples

Embodiment 1

[0023] Prepare the earthworm antimicrobial peptide hydrolyzate according to the following specific steps:

[0024] 1. Collect fresh earthworms, put the earthworms mixed with vermicompost in the sun, because earthworms are afraid of light, they will drill into the bottom layer, scrape off the surface layer of vermicompost, and then continue to drill down, and then scrape the surface layer of vermicompost until the earthworms form a ball , only a small amount of vermicompost remains;

[0025] 2. Soak the fresh earthworms obtained in step 1 in water, stir, wash 3 to 5 times until clean, and filter out the water;

[0026] 3. The earthworms, brown sugar, water, and sorbic acid that have been filtered dry are hydrolyzed for 20 hours in a water bath at a constant temperature of 40° C. according to a weight ratio of 1:0.2:1:0.007;

[0027] 4. Filter the impurities to obtain the earthworm antimicrobial peptide hydrolyzate.

Embodiment 2

[0029] Prepare the earthworm antimicrobial peptide hydrolyzate according to the following specific steps:

[0030] 1. Collect fresh earthworms, put the earthworms mixed with vermicompost in the sun, because earthworms are afraid of light, they will drill into the bottom layer, scrape off the surface layer of vermicompost, and then continue to drill down, and then scrape the surface layer of vermicompost until the earthworms form a ball , only a small amount of vermicompost remains;

[0031] 2. Soak the fresh earthworms obtained in step 1 in water, stir, wash 3 to 5 times until clean, and filter out the water;

[0032] 3. Expose the drained earthworms in the sun to make dried earthworms;

[0033] 4. The dried earthworms, brown sugar, water, and potassium sorbate were hydrolyzed for 16 hours in a water bath at a constant temperature of 60° C. according to a weight ratio of 1: 1.1: 10: 0.036;

[0034] 5. Filter the impurities to obtain the earthworm antimicrobial peptide hydrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com