Halogen-free flame-retardant phenolic epoxy glass cloth laminate and preparation method thereof

A phenolic epoxy glass and alkali-free glass cloth technology, applied in glass/slag layered products, chemical instruments and methods, layered products, etc., can solve problems such as loss of thermal stability of the system, and achieve excellent flame retardant effect, Realize the effect of industrialized production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Mix the glycidoxytrimethoxysilane coupling agent with water at a weight ratio of 1:9, stir and dissolve at room temperature, and use a vertical gluing machine to impregnate the alkali-free glass cloth with the coupling agent solution, The non-alkali glass cloth was impregnated at 40°C, and dried at 80°C to obtain the non-alkali glass cloth treated with the coupling agent.

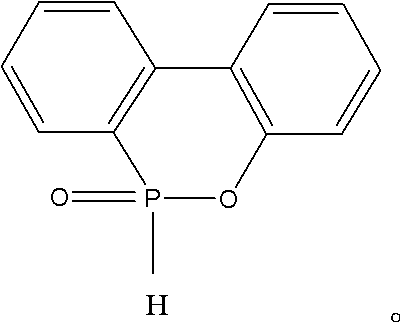

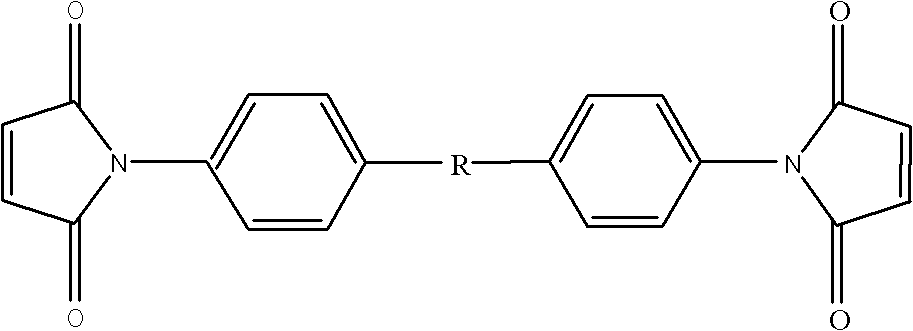

[0039] (2) Add 864 grams (4 moles) of DOPO and 1432 grams (4 moles) of 4,4'-diphenylmethane bismaleimide (BMI) into the reactor, heat up, stir, and melt at 90°C for reaction After cooling for 0.5 hour, 2251 g of solid product of halogen-free phosphorus-containing nitrogen-containing flame retardant was obtained, denoted as DB, and the yield was 98%.

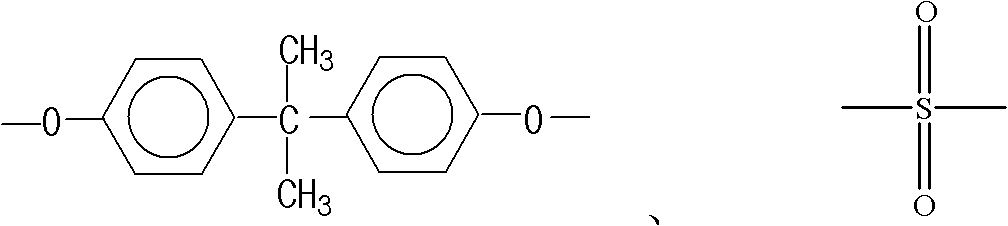

[0040] (3) At room temperature, 360 grams of thermoplastic novolac epoxy resin, 160 grams of thermosetting phenol formaldehyde resin, 400 grams of halogen-free phosphorus-containing nitrogen-containing flame retardant DB, 80 grams of 4,4'-bis(4-amin...

Embodiment 2

[0042] (1) Mix the γ-aminopropyltrimethoxysilane coupling agent with water at a weight ratio of 1:10, stir and dissolve at room temperature, and use a vertical gluing machine to impregnate the alkali-free glass cloth with the coupling agent solution, The non-alkali glass cloth is impregnated at 50°C, and dried at 90°C to obtain the non-alkali glass cloth treated with the coupling agent.

[0043] (2) Add 864 grams (4 moles) of DOPO and 1432 grams (4 moles) of 4,4'-diphenylmethane bismaleimide (BMI) into the reactor, heat up, stir, and melt at 120°C After cooling for 1.0 hour, 2251 g of a halogen-free, phosphorus- and nitrogen-containing flame retardant was obtained as a solid product, denoted as DB, with a yield of 97%.

[0044](3) At room temperature, mix 240 grams of glycidylamine polyfunctional epoxy resin, 240 grams of bisphenol A epoxy resin, 160 grams of thermosetting phenol formaldehyde resin, 320 grams of thermoplastic o-cresol formaldehyde resin, 900 grams of halogen-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com