Environmentally-friendly lithographic printing plate base and preparation process thereof

A lithographic printing and environmental protection technology, applied in the field of lithographic printing plate base and its preparation process, can solve problems such as poor fastness, affecting use, and inability to print

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

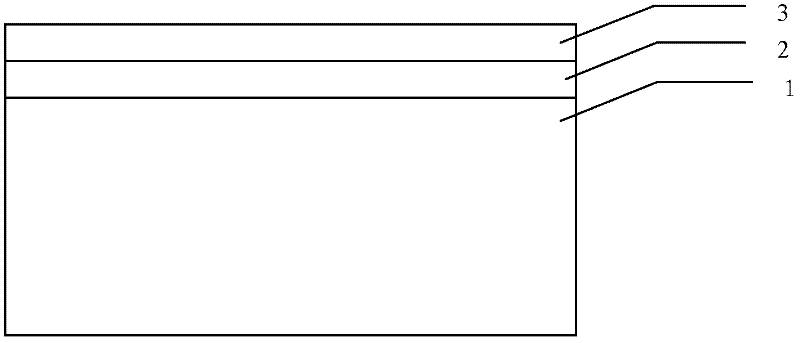

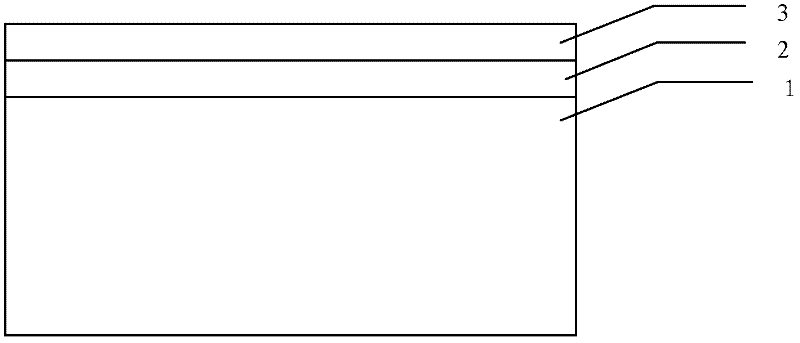

Image

Examples

Embodiment 1

[0054] In this embodiment 1, the plate base material is made of metal aluminum plate with a thickness of 0.05-0.5 mm. The process of preparing for printing is to first clean the metal aluminum plate to remove dirt and oil. Coating adhesive layer on aluminum plate then, the formula that adhesive layer coating is epoxy resin aqueous solution (50%) 35 parts, phenolic resin aqueous solution (30%) 15 parts, water 50 parts, the above components are stirred and dispersed, Make a uniform coating solution, apply it on the aluminum plate by dip coating, and then bake it in an oven at 200°C for 5 minutes to solidify the coating solution into a bonding layer with a thickness of 2-15 μm, and then apply the pro- water layer. The coating liquid formula of the hydrophilic layer is 100 parts of polyvinyl alcohol (10% aqueous solution), 40 parts of nano or micron zinc oxide, 5 parts of hexamethylol melamine resin (50% aqueous solution), sorbitan ester polyoxygen Vinyl ether (4% aqueous soluti...

Embodiment 2

[0058] In this embodiment, the plate base material is also made of metal aluminum plate with a thickness of 0.05-5 mm. The process of preparing the printing plate base is also to first clean the aluminum plate to remove dirt and oil, and then apply an adhesive layer on the aluminum plate. The formula of the bonding layer is 40 parts of water-soluble saturated polyester resin (60%), 10 parts of hexahydroxymelamine resin (50%) and 50 parts of water. Stir and disperse the above components to form a uniform coating solution, then coat the aluminum plate by dip coating, and then bake it in an oven at 200°C for 7 minutes to cure the coating into a bonding layer. Coating thickness is 4-15um. Then coat the hydrophilic layer, and the formula of the hydrophilic layer coating solution is 50 parts of polyvinyl alcohol (10%). 10 parts of acrylic styrene emulsion (40%). 30 parts of nanometer or micron titanium dioxide. Sodium hexametaphosphate (10%) 5 parts. Diisooctyl sodium succinate (4...

Embodiment 3

[0060] The plate base material is a polyester film base with a thickness of 80 μm to 100 μm, and then a bonding layer is coated on the film base. The formula of the bonding layer coating solution is 200 parts of vinylidene chloride emulsion (40%), gelatin (3% ) 400 parts, 100 parts of sodium hydroxide aqueous solution (2%), and 600 parts of resorcinol aqueous solution (15%) were mixed and then stirred and dispersed to form an adhesive layer coating liquid. The coating liquid coating method is dip coating, the coating thickness is 3---10μm, the drying temperature is 90---110°C, and the heating is 5---10 minutes. After drying, a bonding layer is formed, and then the bonding layer is formed. coated with a hydrophilic layer.

[0061] The formula and coating method of the hydrophilic layer coating solution, the drying temperature and time are the same as in Example 1, and the use of the plate base in printing is also the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com