Biological complex enzyme for sludge recycling and use method thereof

A bio-enzyme and resource-based technology, applied in the fields of botanical equipment and methods, biological sludge treatment, and application, can solve the problems of poor degradability, multiple labor, and high site and facility requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

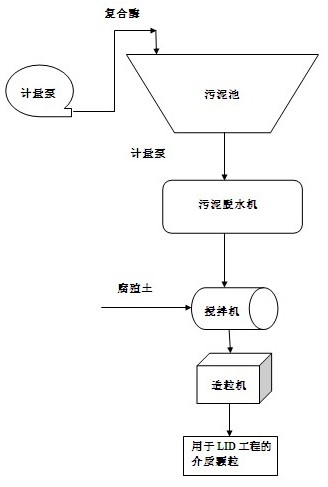

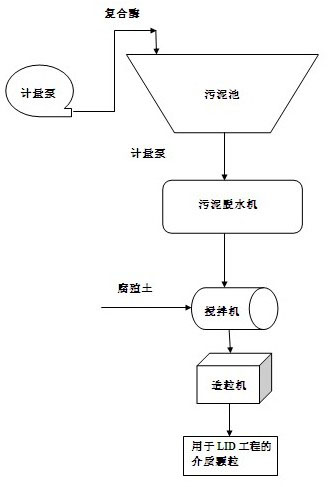

Image

Examples

Embodiment 1

[0062] Get 10 kg of sludge with a solid content of 2.5% from the thickening tank and put it into a 5-gallon plastic bucket. Then take 10 ml of compound enzyme and dilute it with pure water at a ratio of 1:100, and then add it into the plastic bucket filled with sludge. After mixing the sludge and compound enzyme, stir with a stirrer at 250 rpm for 10 minutes, then add 50 ml of 30% hydrogen peroxide (peroxide), and continue to stir for 4 hours.

[0063] To simulate dehydration, add 1 gram of chitosan bioflocculant in a plastic bucket and stir evenly until flowers bloom. After the sludge settles, first pour out the supernatant in the bucket, and then pour the flocculated and precipitated sludge on the filter paper to continue dehydration for 30 minutes.

[0064] The sludge dehydrated through the above process is weighed, and the humus soil is mixed with the dewatered sludge according to the proportion of 40% of the weight of the dewatered sludge. After uniform stirring, it is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com