In-situ crosslinked alginate hydrogels and preparation method thereof

A sodium alginate, in-situ cross-linking technology, applied in aerosol delivery, liquid delivery, ointment delivery, etc., to achieve the effects of good biocompatibility, easy preparation, mild and simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

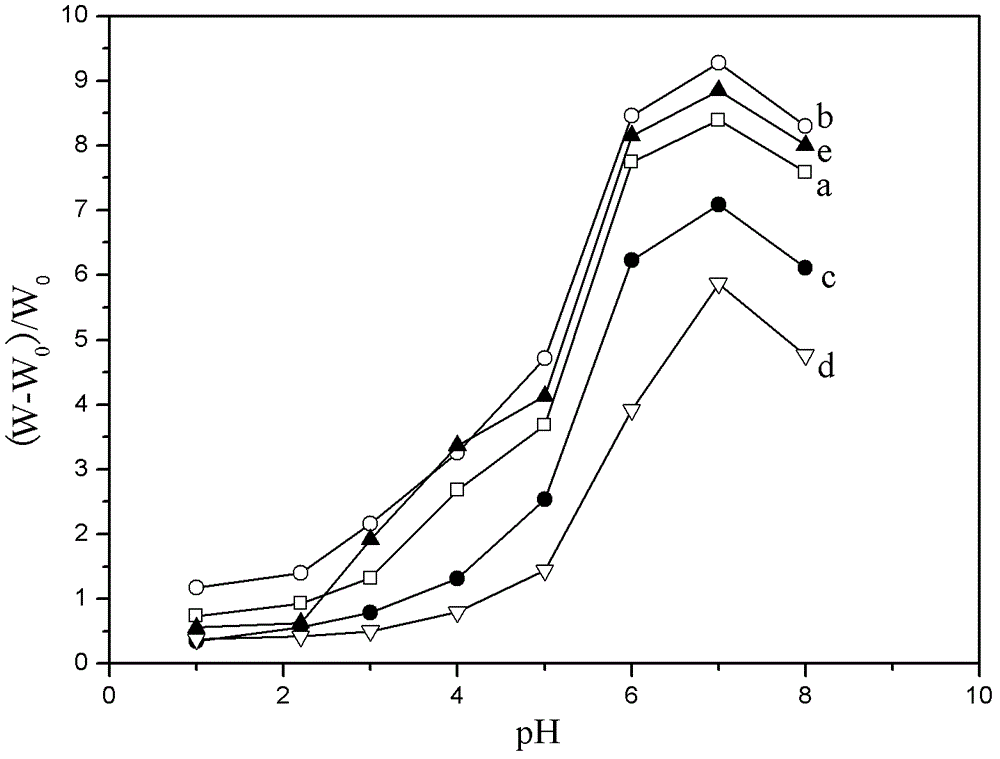

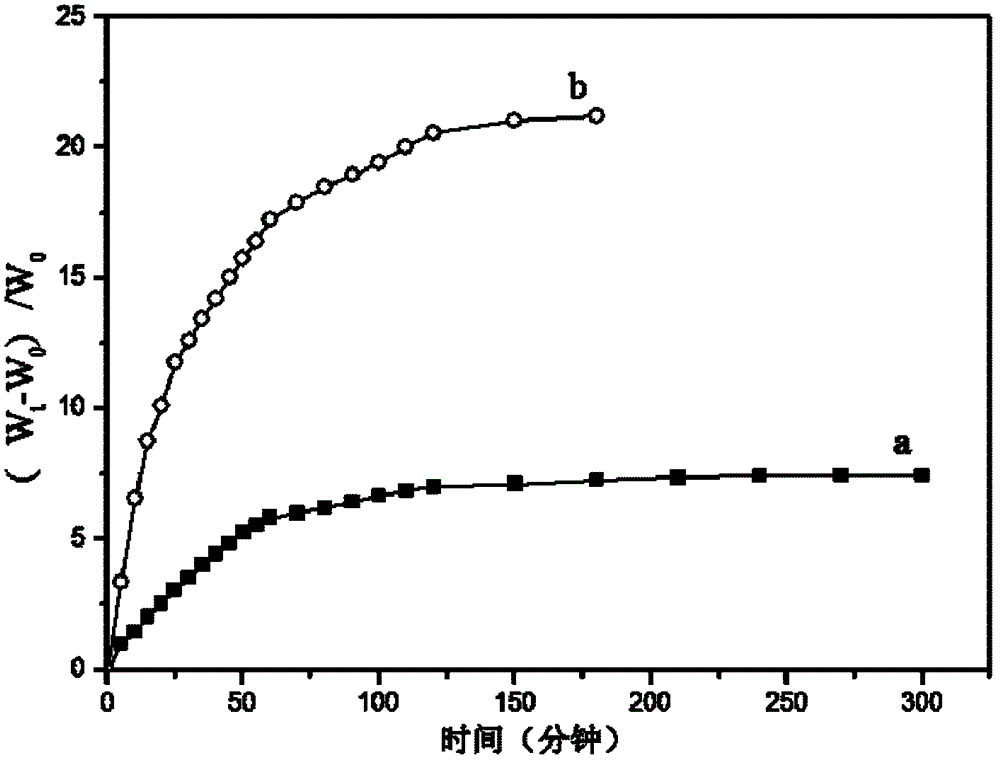

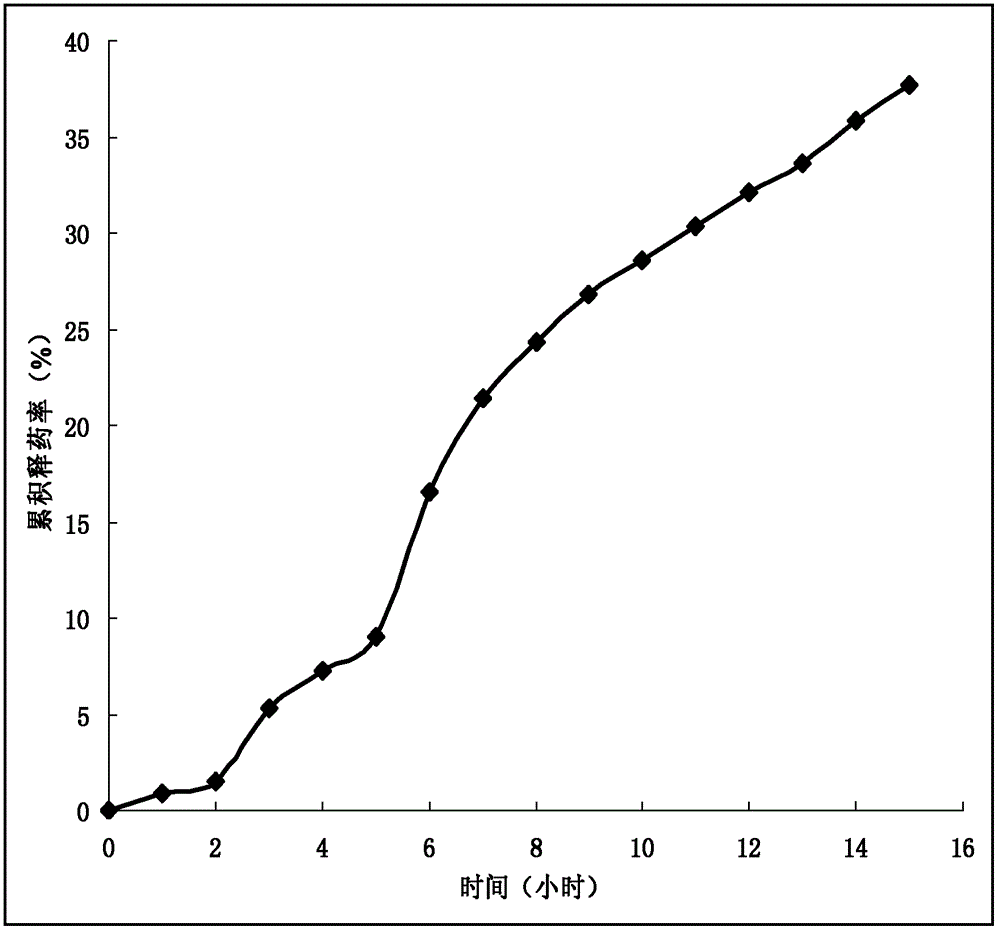

[0030] The preparation method of the in-situ cross-linked sodium alginate hydrogel provided by the present invention specifically adopts the following method to prepare the in-situ cross-linked sodium alginate hydrogel, and the steps include:

[0031] (1) Preparation of thiolated sodium alginate:

[0032] According to the proportion, add the organic solution of carbodiimide hydrochloride and N-hydroxysuccinimide to the sodium alginate aqueous solution, after stirring evenly, add the organic solution of p-mercaptoaniline dropwise under the condition of low temperature, dark and nitrogen protection. Continue to stir for 1-24 hours. After the reaction, adjust the pH value of the reaction system to 6, add ethanol to precipitate and freeze-dry to obtain thiolated sodium alginate with different thiol content; the low temperature is ≤10°C.

[0033] (2) Preparation of in situ cross-linked sodium alginate hydrogel:

[0034] According to the proportion, the aqueous solution of thiolate...

Embodiment 1

[0037] Dissolve 0.15 g of sodium alginate in 5 mL of deionized water to obtain a 3% sodium alginate aqueous solution by weight, add 1 mL of carbodiimide hydrochloride and N-hydroxysuccinimide in dimethyl sulfoxide (seaweed The molar ratio of sodium acid sugar unit to carbodiimide hydrochloride is 1:1.1, and the molar ratio of carbodiimide hydrochloride to N-hydroxysuccinimide is 1:1), stir well, and avoid Add 1 mL of 9% (W / V) dimethyl sulfoxide solution of p-mercaptoaniline dropwise under light and nitrogen protection conditions, stir for 5 hours, adjust the pH value to 6 with 0.1M hydrochloric acid, add ethanol to precipitate, and then Wash twice with a small amount of ethanol, and freeze-dry to obtain mercaptolated sodium alginate with a mercapto group content of 586.1 μmol mercapto group / g polymer.

[0038]Dissolve 0.15g of thiolated sodium alginate in 5mL of deionized water to obtain a 3% (W / V) aqueous solution of thiolated sodium alginate, then pour it into the mold, and ...

Embodiment 2

[0040] Dissolve 0.10 g of sodium alginate in 5 mL of deionized water to obtain a 2% sodium alginate aqueous solution, add 1 mL of carbodiimide hydrochloride and N-hydroxysuccinimide in dimethyl sulfoxide (seaweed The molar ratio of sodium acid sugar unit to carbodiimide hydrochloride is 1:1.1, and the molar ratio of carbodiimide hydrochloride to N-hydroxysuccinimide is 1:1), stir well, and avoid Add 1 mL of 5% (W / V) dimethyl sulfoxide solution of p-mercaptoaniline dropwise under light and nitrogen protection conditions, stir and react for 5 hours, adjust the pH value to 6 with 0.1M hydrochloric acid, add ethanol to precipitate, and then Wash twice with a small amount of ethanol, and freeze-dry to obtain mercaptolated sodium alginate with a mercapto group content of 470.7 μmol mercapto group / g polymer.

[0041] Dissolve 0.10g of mercaptolated sodium alginate in 5mL of deionized water to obtain a 2% (W / V) mercaptolated sodium alginate aqueous solution, then pour it into the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com