Preparation method of organosiloxane modified WPU/PVA (waterborne polyurethane/polyvinyl alcohol) film

A technology of organosiloxane modification, applied in the field of preparation of organosiloxane modified WPU/PVA film, to achieve the effect of maintaining sports activity, good effect, high anti-sticking and cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

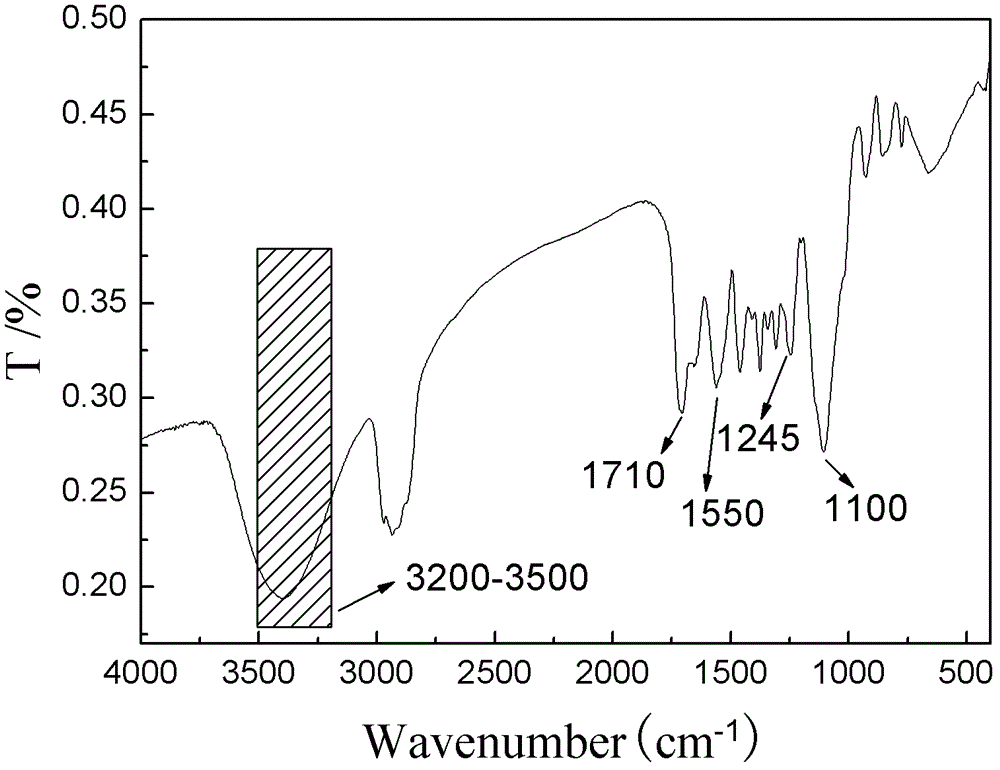

Method used

Image

Examples

Embodiment 1

[0061] 7.4 grams of isophorone diisocyanate (IPDI), 11.7 grams of polypropylene glycol PPG-220, 0.6 grams of 1,4-butanediol (1,4-BD), 0.17 grams of trimethylolpropane (TMP), butyl Add 10 grams of ketone and 0.05 grams of dibutyltin dilaurate (DBTDL) into a 250 mL three-necked flask, stir at a speed of 100 rpm, react at 80 ° C for 1.5 hours, and then add 1.1 grams of dimethylol propionic acid (DMPA), React at 80°C for 5 hours at a stirring speed of 100 rev / min, cool down to 40°C, add 0.37 g of γ-aminopropyltriethoxysilane, react at a stirring speed of 100 rev / min for 20 minutes, then dropwise add 0.95 gram of triethylamine, and reacted at 30-40°C for 30 minutes at a stirring speed of 100 rev / min. Stir the deionized water at a speed of 500 rpm, and continue to stir for 15 minutes after the dropwise addition is completed, then add dropwise an aqueous solution of ethylenediamine, which is prepared by using 0.25 grams of ethylenediamine and 10 grams of water, and add dropwise Duri...

Embodiment 2

[0074] The preparation method of this example is the same as that of Example 1, except that 20 g of polyvinyl alcohol (PVA) aqueous solution with a mass percentage concentration of 5% and 10 g of organosiloxane modified WPU emulsion are mixed to form a film, and the obtained organosiloxane modified The water swelling rate, solvent swelling rate, tensile strength and elongation at break of the permanent WPU / PVA film are tested by the same method at 40°C, and thermal analysis test is carried out.

[0075] The test results are as follows:

[0076]The water swelling rate of the membrane is 62.7%, the solvent swelling rate is 50.3%, the tensile strength is 33.5MPa, and the elongation at break is 55.3%. Comparing these values with the corresponding values of M0, it can be seen that the membrane obtained in this embodiment has higher resistance to solvent swelling, higher strength and flexibility.

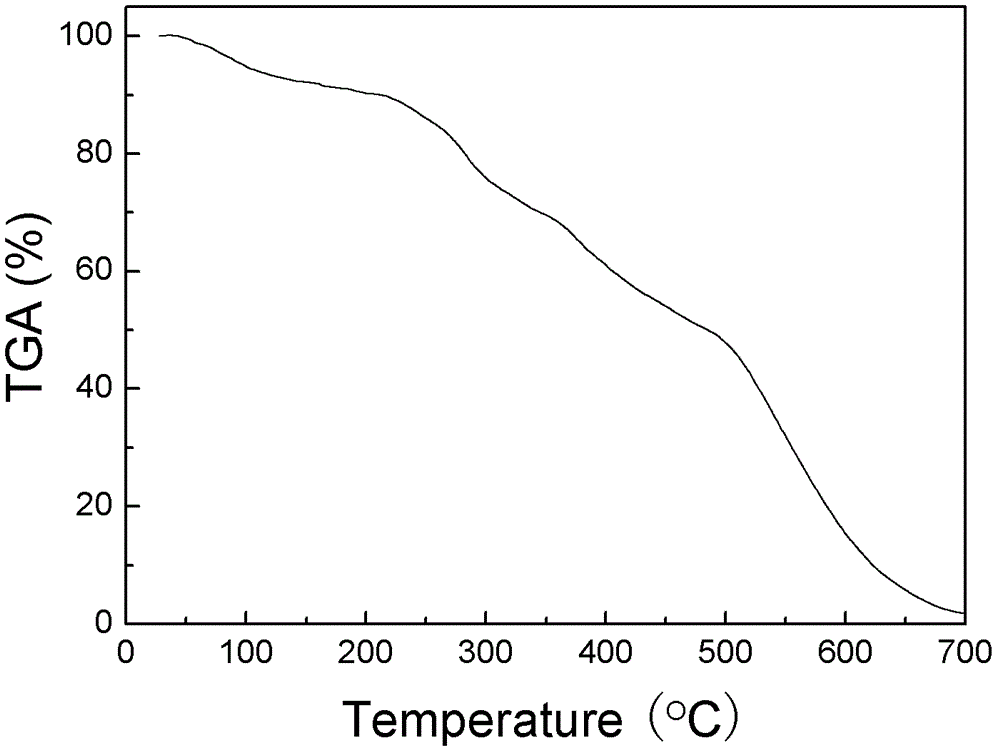

[0077] Thermal analysis spectrum such as image 3 shown.

[0078] Depend on ...

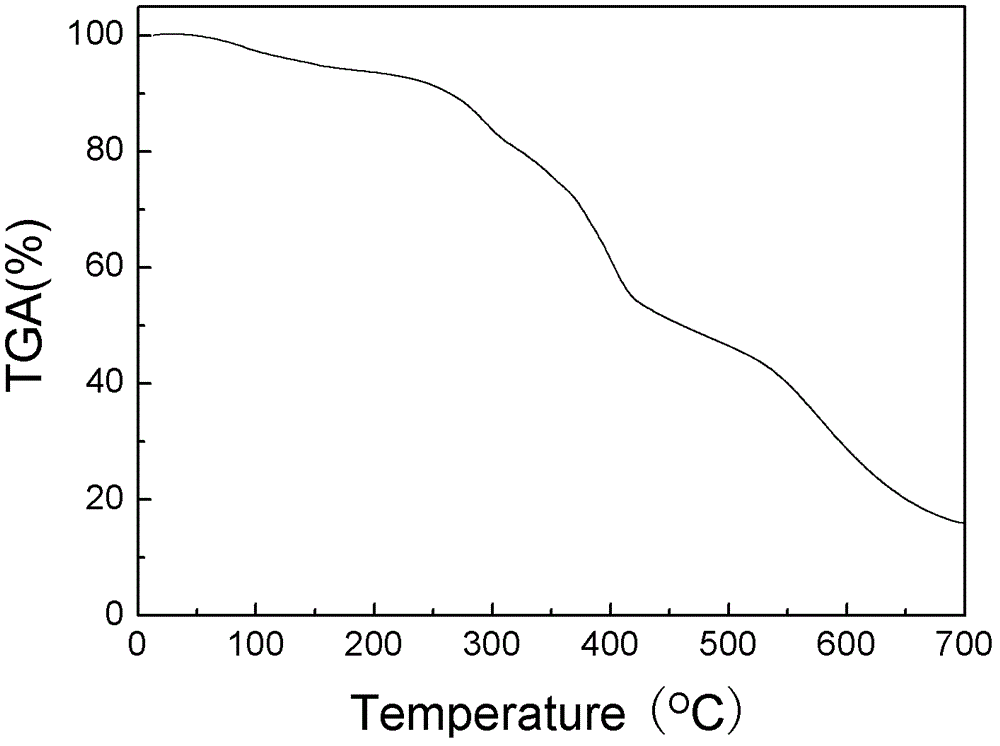

Embodiment 3

[0081] The preparation method of this example is the same as that of Example 1, except that 20 g of polyvinyl alcohol (PVA) aqueous solution with a mass percentage concentration of 5% and 5 g of organosiloxane modified WPU emulsion are mixed to form a film, and the obtained organosiloxane modified The water swelling rate, solvent swelling rate, tensile strength and elongation at break of the permanent WPU / PVA film are tested by the same method at 40°C, and thermal analysis test is carried out.

[0082] The test results are as follows:

[0083] The water swelling rate of the film is 106.4%; the solvent swelling rate is 71.7%; the tensile strength is 38.4MPa; the elongation at break is 30.9%. The Td value was 230.4°C. Comparing these values with the corresponding values of M0, it can be seen that the membrane obtained in this embodiment has higher resistance to solvent swelling, higher strength and flexibility.

[0084] The membrane is subjected to pervaporation test, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com