Manufacturing method of field blocking type semiconductor device

A production method and field blocking technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high cost, not higher than 500 degrees Celsius, and low ion efficiency of the field blocking layer, reaching the depth range Large and good activation rate, impurity concentration and concentration distribution adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

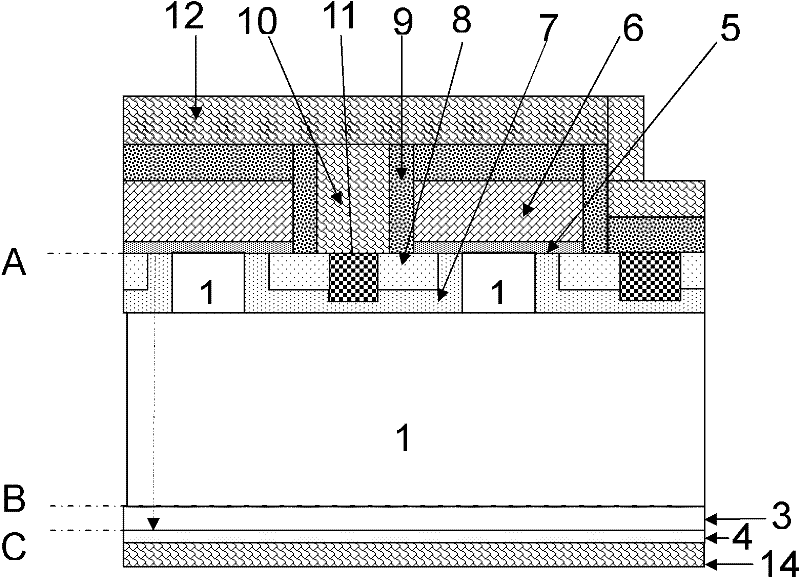

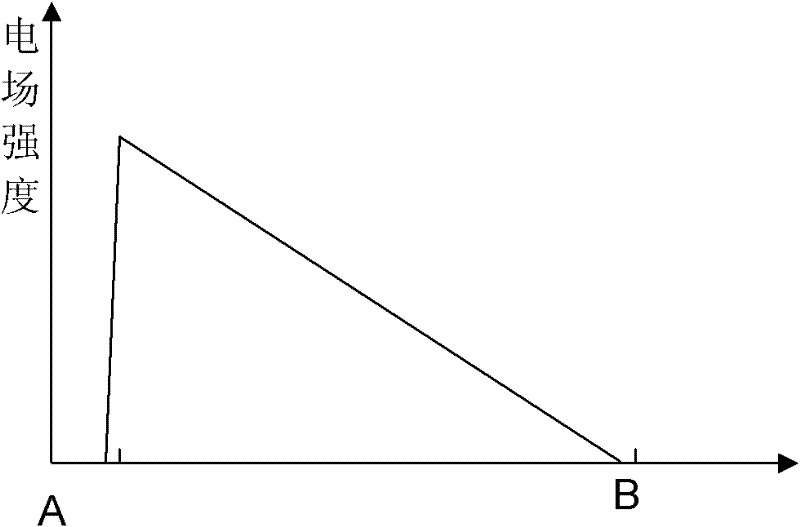

[0036] Such as Figure 6 Shown is a flow chart of a method for fabricating a field-stop type semiconductor device according to an embodiment of the present invention. The field-stop type semiconductor device in Embodiment 1 of the present invention is illustrated by taking a field-stop type IGBT device with a reverse breakdown voltage of 3300V and an N-type drift region as an example. The field-stop type IGBT with an N-type drift region The first conductivity type of the device is N-type; the method for manufacturing a field-blocking semiconductor device according to the embodiment of the present invention includes the following steps:

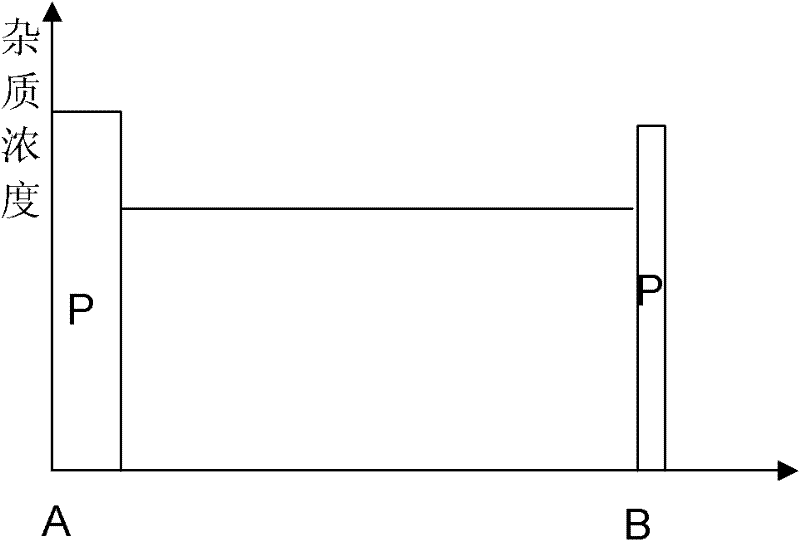

[0037] Step 1, such as Figure 7 As shown, first provide an impurity concentration C1 = 2.4E13CM -3 1. An N-type silicon chip 1 with a resistivity of 180 ohm.cm, the thickness of the silicon chip 1 is more than 700 microns; an oxide film of 5000 angstroms to 20000 angstroms is grown on the front side of the silicon chip 1, that is, on the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com