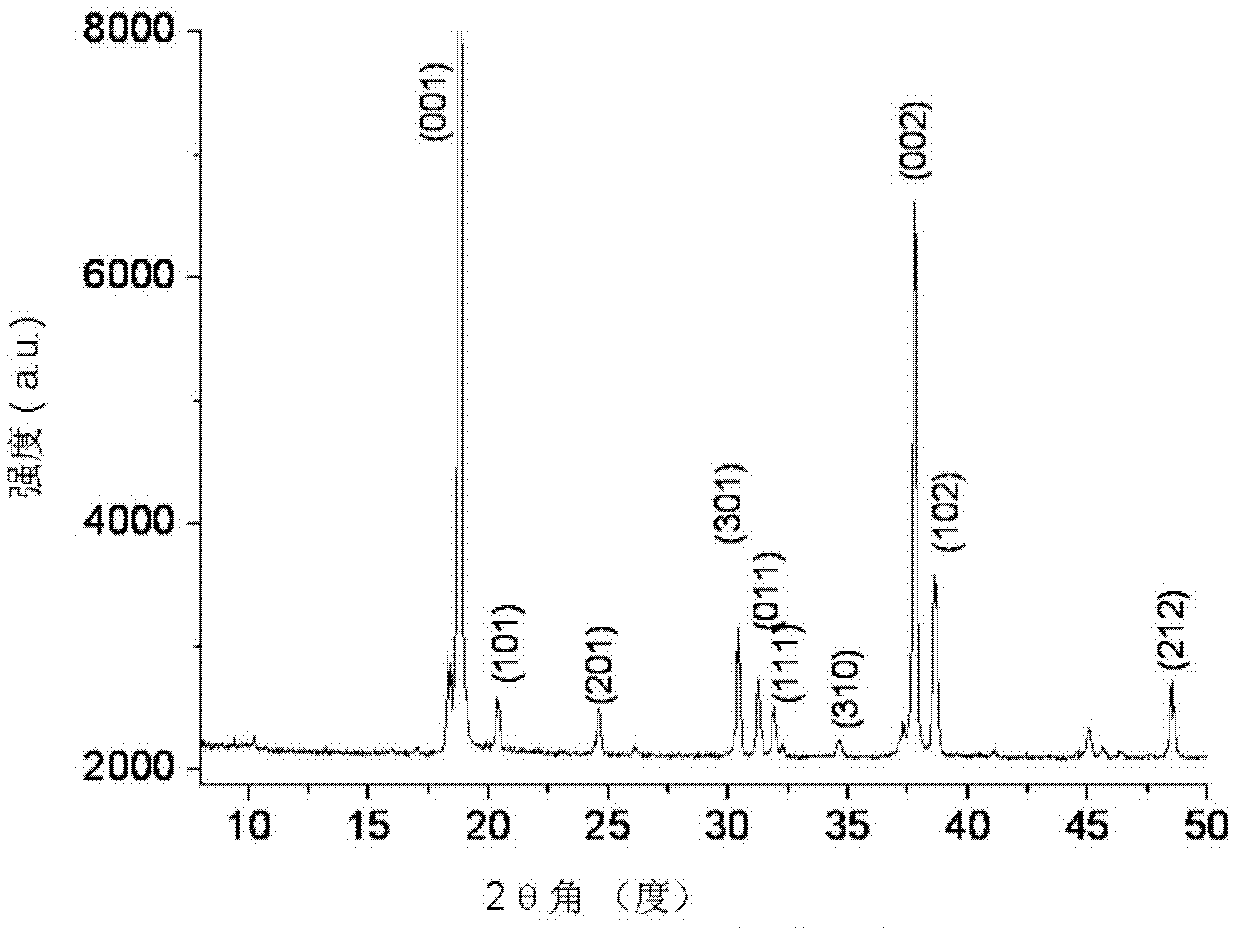

Preparation method of NaV2O5 crystal material with right angle morphology

A technology of crystal materials and right angles, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problem of small crystal particles, and achieve the effect of simple preparation process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

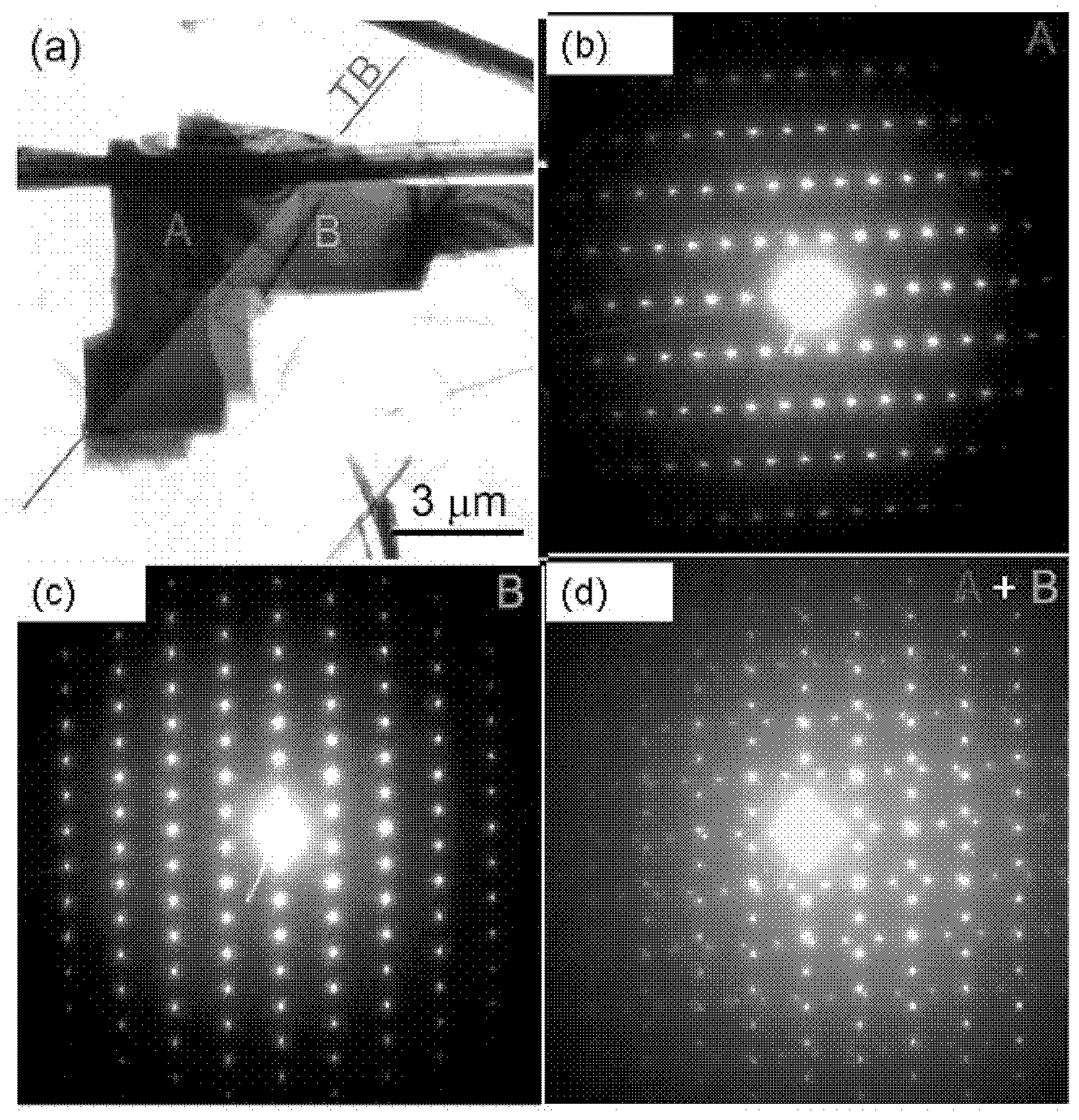

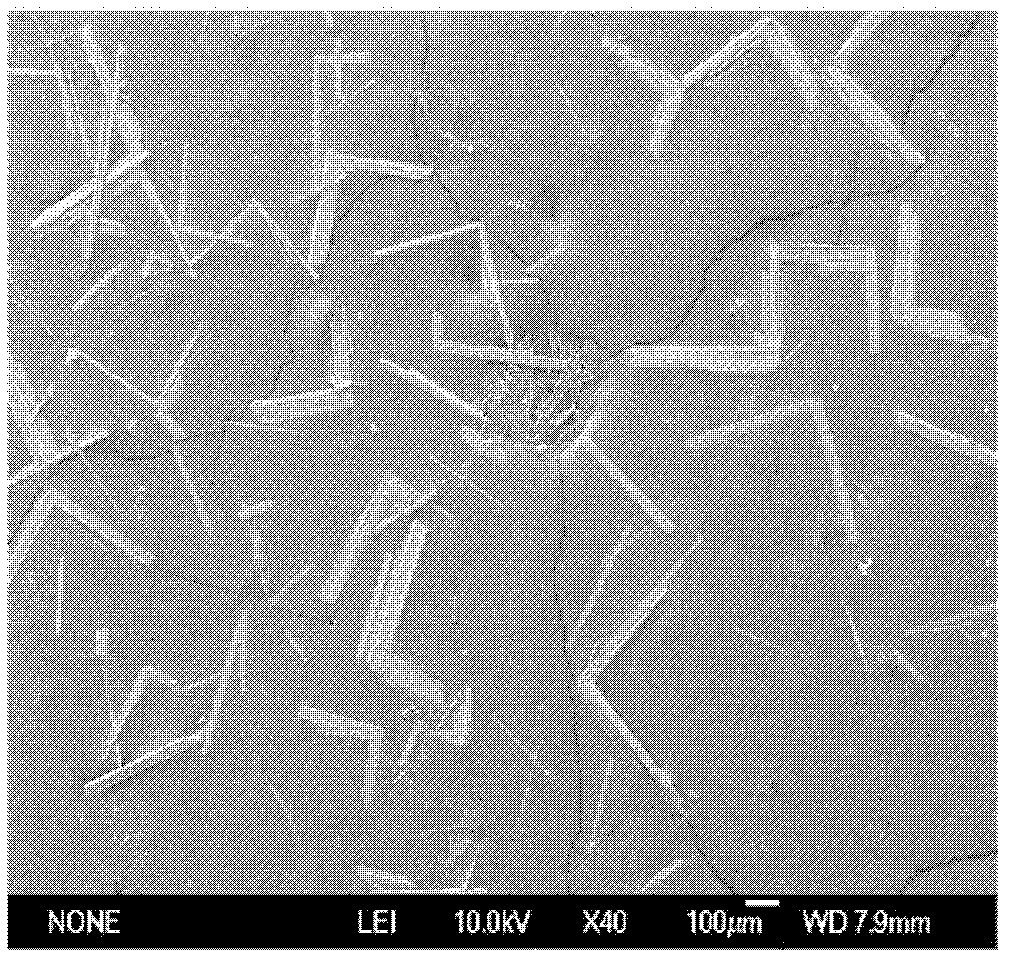

Embodiment 1

[0030] Embodiment 1: Dissolve 0.210g (0.001mol) of organic matter trimesic acid in 5g (0.28mol) of water, add 1.75ml NaOH solution (concentration is 2mol / l) after stirring at normal temperature for 5 minutes, continue to stir at normal temperature for about 15 Minutes, then add a solvent composed of 2.5g water (0.14mol) and 2.5g (0.055mol) absolute ethanol to obtain a colorless and transparent solution, and finally add 0.2339g (0.002mol) NH 4 VO 3 , the solution at this time was milky yellow and turbid, and after stirring for 40 minutes, the measured mixture pH was 7.5-8.0, (the mol ratio of the mixture is NH 4 VO 3 : Trimellitic acid: NaOH=2: 1: 3.5; The quality of every mole of trimesic acid corresponding solvent is 5 kilograms, water in the solvent: the mass ratio of ethanol=1. Transfer the mixture into a stainless steel reaction kettle lined with polytetrafluoroethylene, put it in a constant temperature drying oven at 180°C for aging for two days, take out the mixture af...

Embodiment 2

[0031] Example 2: Dissolve 0.210g (0.001mol) organic matter trimesic acid in 5g (0.28mol) water, add 1.75ml NaOH solution (2mol / l) after stirring at normal temperature for 5 minutes, and continue stirring for about 15 minutes at normal temperature, Then add a solvent consisting of 2.5g (0.14mol) of water and 2.5g (0.055mol) of absolute ethanol to obtain a colorless and transparent solution, and finally add 0.117g (0.001mol) of NH 4 VO 3 , the solution at this time was milky yellow and turbid, and after stirring for 60 minutes, the pH measured was 7.5-8.0, (the mol ratio of the mixture was NH 4 VO 3 : Trimellitic acid: NaOH=1: 1: 3.5; The quality of every mole of trimesic acid corresponding solvent is 10 kilograms, water in the solvent: the mass ratio of ethanol=1. Transfer the mixture into a stainless steel reaction kettle lined with polytetrafluoroethylene, put it in a constant temperature drying oven at 180 ° C for one month, then take out the sample and filter it, dry it ...

Embodiment 3

[0032] Example 3: Dissolve 0.210g (0.001mol) organic matter trimesic acid in 2.5g (0.14mol) water, add 1.75ml NaOH solution (2mol / l) after stirring at normal temperature for 5 minutes, and continue stirring for about 15 minutes at normal temperature , and then add a solvent consisting of 2.5g (0.055mol) of absolute ethanol solution to obtain a colorless and transparent solution, and finally add 0.4679g (0.004mol) of NH to the mixed solution 4 VO 3 , a yellow turbid liquid was obtained, and the measured pH was 7.0-7.2 after stirring for 40 minutes, and the molar ratio of the mixture was NH 4 VO 3 : Trimellitic acid: NaOH=4: 1: 3.5; The quality of every mole of trimesic acid corresponding solvent is 2.5 kilogram . Transfer the mixture into a stainless steel reaction kettle lined with polytetrafluoroethylene, put it in a constant temperature drying oven at 180 ° C for 7 days, then take out the sample and filter it, dry it in a constant temperature drying oven at 40 ° C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com