Phosphate ester polymer intumescent flame retardant and preparation method thereof

An intumescent flame retardant and phosphoric acid ester technology, which is applied in the design and preparation of phosphoric acid ester polymers, can solve the problems of uncontrollable conditions, uneasy storage, harsh conditions, etc. High carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

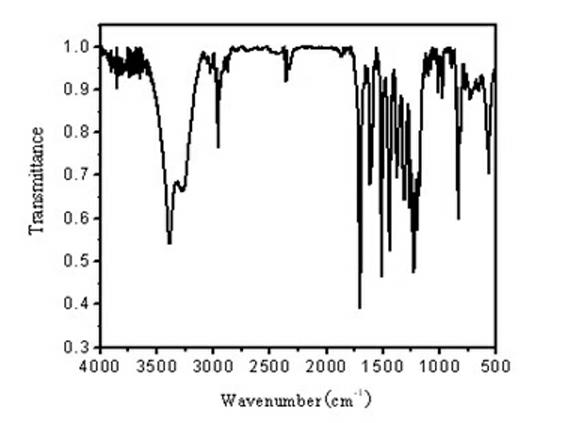

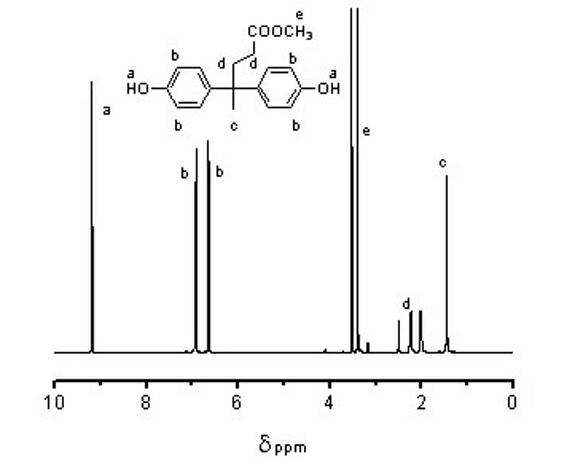

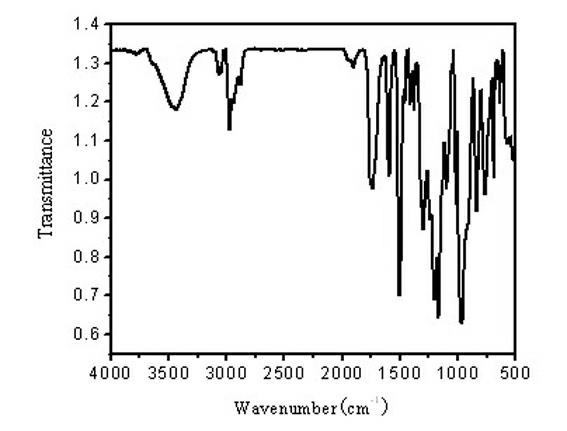

[0045] Add 20mmol of bisphenolic acid, 50ml of methanol, and 1mmol of catalyst p-toluenesulfonic acid into a 250ml flask, heat and reflux for 8h under stirring, cool to room temperature after the reaction is over, and rotary evaporate excess methanol, then add deionized water to precipitate, Rapidly stirred and filtered to obtain the crude product with the general structure formula (IV), recrystallized with methanol / water (volume ratio 50:1) to obtain a white solid with a melting point of 132-133°C and a yield of 80% (see figure 1 , 1 H NMR see figure 2 ). The compound with the general structural formula (Ⅳ), namely methyl bisphenolate (5mmol, 1.005g), 1mol / L NaOH (10mmol, 0.4g) solution, phase transfer catalyst tetrabutylammonium bromide 0.25mmol and deionized water Add 25ml into the three-necked flask, mechanically stir at 25°C to dissolve all the above mixture, then quickly add 25ml of dichloromethane solution of phenyl phosphate dichloride, stir rapidly, and after reac...

Embodiment 2

[0049] Add 20mmol of bisphenolic acid, 50ml of ethanol, 1mmol of catalyst concentrated sulfuric acid into a 250ml flask, heat and reflux for 8h under stirring, cool to room temperature after the reaction is over, and spin evaporate excess ethanol, then add hot deionized water to precipitate, and stir rapidly The crude product of ethyl bisphenolate was obtained by filtration, and recrystallized with methanol / water to obtain a white solid with a melting point of 128-129°C and a yield of 78%. Add 5mmol of ethyl bisphenolate, 10mmol of sodium hydroxide, 0.25mmol of phase transfer catalyst tetrabutylammonium chloride and 25ml of deionized water into the three-necked flask, mechanically stir at 25°C to dissolve all the EDP, and then quickly Add 25ml of dichloromethane solution containing 5mmol of phenyl phosphate dichloride, stir rapidly, and after reacting for 1h, filter the product with suction, wash with a large amount of deionized water and ethanol, and dry in vacuum at 70°C to o...

Embodiment 3

[0052] Add 20mmol of bisphenolic acid, 50ml of ethanol, and 1mmol of catalyst p-toluenesulfonic acid into a 250ml flask, heat and reflux for 8h under stirring, cool to room temperature after the reaction is over, and spin out excess ethanol, then add hot deionized water Precipitate, stir and filter rapidly to obtain the crude product of ethyl bisphenolate, recrystallize with methanol / water to obtain a white solid, melting point 128~129°C, yield 78%. Add 5mmol of ethyl bisphenolate, 10mmol of sodium hydroxide, 0.25mmol of phase transfer catalyst tetrabutylammonium bromide and 25ml of deionized water into a three-necked flask, mechanically stir at 25°C to dissolve all the EDP, and then quickly Add 25ml of dichloromethane solution containing 5mmol of phenyl phosphate dichloride, stir rapidly, and after reacting for 1h, filter the product with suction, wash with a large amount of deionized water and ethanol, and dry in vacuum at 70°C to obtain the general structural formula (II) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com