Rubber lining material of corrosion-resistant rubber lining butterfly valve and production method thereof

A corrosion-resistant and rubber-lined technology, which is applied in the rubber-lined rubber material of corrosion-resistant rubber-lined butterfly valves and its preparation field, can solve the problems of expensive raw materials, high cost, relatively high requirements for sealing and corrosion resistance, and achieve low material cost , good airtight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

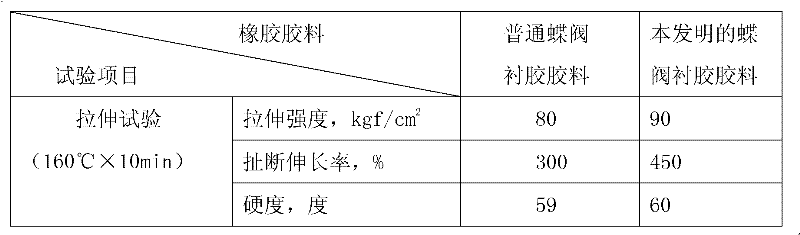

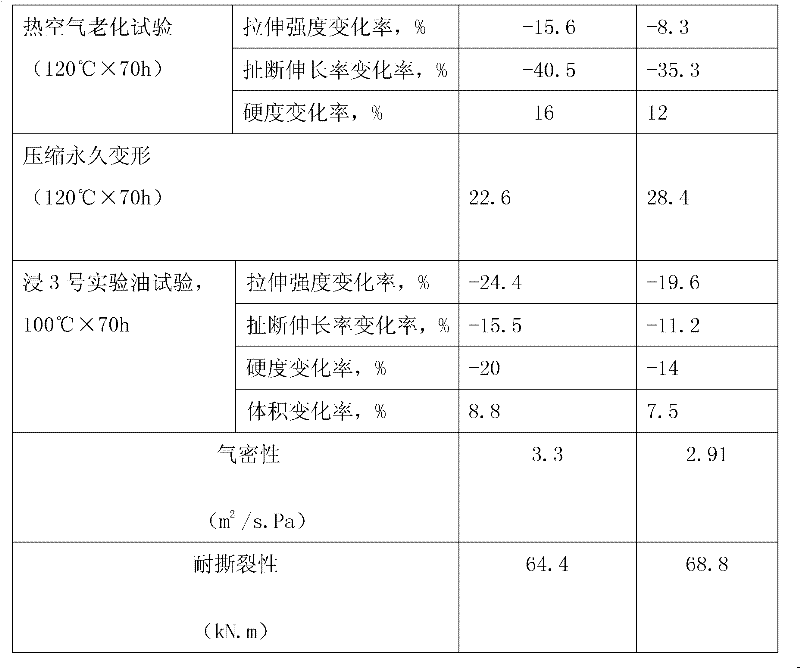

Examples

Embodiment 1

[0031] 1. Raw material preparation:

[0032] Preparation of raw materials for rubber compound:

[0033] Weigh nitrile rubber 3305 90 sulfur 0.4, magnesium oxide 5, stearic acid 2, antioxidant 2,5-ditertbutyl hydroquinone-DTBHQ1, antioxidant RD 1.5, antioxidant 4010NA 1.5, paraffin wax 2, Fast extrusion carbon black N660 24, high wear-resistant carbon black N330 63, dioctyl ester 20, calcium carbonate 30, accelerator M 2, accelerator TMTD1, accelerator TETD1,

[0034] Preparation of raw materials for B rubber compound:

[0035] Weigh homopolyether rubber 85, copolyether rubber 15, zinc stearate 1, anti-aging agent RD 2, gelatin T-78 0.5, rhine wax 1.5, quick press carbon black 50, diatomite 12 , dioctyl ester 6, lead tetroxide 5, vulcanizing agent TCY 0.8, accelerator Na-22 1.5.

[0036] 2. The preparation method of the rubber-lined rubber material of the corrosion-resistant rubber-lined butterfly valve includes the following steps:

[0037] The first step: Prepare A rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com