Copper Damascus process MIM (metal-insulator-metal) capacitor manufacturing process and structure

A technology of metal capacitors and manufacturing processes, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as reducing the area of MIM capacitors, and achieve the effect of increasing capacitor density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

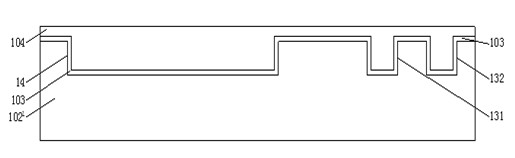

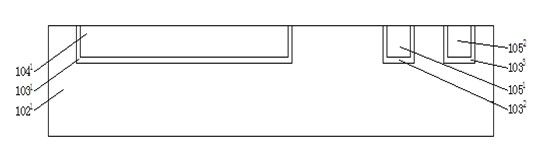

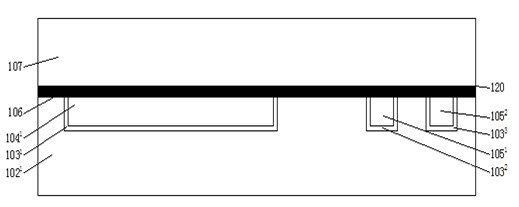

[0045] Such as Figure 1a As shown in -n, the present invention provides a copper damascene process metal-insulator-metal capacitor manufacturing process, wherein the double-layer metal-insulator-metal capacitor structure and its copper damascene manufacturing process can be fully compatible with CMOS logic circuits and inductance, and increase the capacitance density of the metal-insulator-metal capacitor, the process method includes the following steps:

[0046] Using Damascus technology, the material is silicon dioxide (SiO 2 ), silicon carbide hydroxide (SiOCH) or fluorine-doped silicon glass (Fluorinated Silicate Glass, referred to as FSG) on the base dielectric layer 102, the first layer located on the base dielectric layer is formed by photolithography. The first photoresist in the shape of the electrode groove and the substrate interconne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com