Surface treatment method for improving copper interconnection reliability

A surface treatment and reliability technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of improving bonding force, reducing damage, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

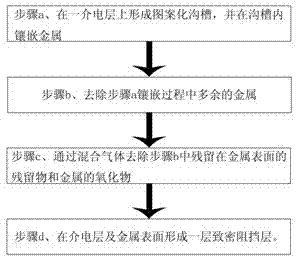

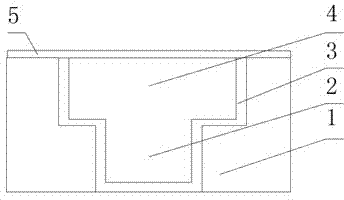

[0035] like figure 1 As shown, a surface treatment method for improving the reliability of copper interconnection of the present invention includes the following steps: figure 2 As shown, step a forms a photoresist material layer on the surface of the low-k dielectric layer 1 formed by chemical vapor deposition or spin coating; forms a predetermined pattern on the photoresist material layer by photolithography; uses the pattern The photoresist material layer is etched on the dielectric layer to form patterned trenches 2 , and the formed patterned trenches 2 may be a single-layer damascene structure or a double-layered damascene structure. A composite structure 3 composed of an adhesion layer, a diffusion barrier layer and a metal seed layer is sequentially formed on the sidewall and bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com