Adsorbent for removing antibiotics from water body, and preparation method and application of adsorbent

A technology of antibiotics and adsorbents, applied in the field of adsorbents for the preparation and removal of antibiotics in water bodies, can solve the problems of poor removal of waste water, small treatment range, and low treatment degree, and achieve the expansion of treatment range and treatment capacity. Convenience and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

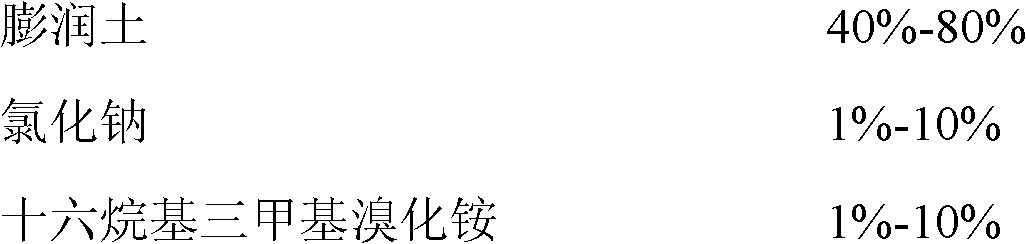

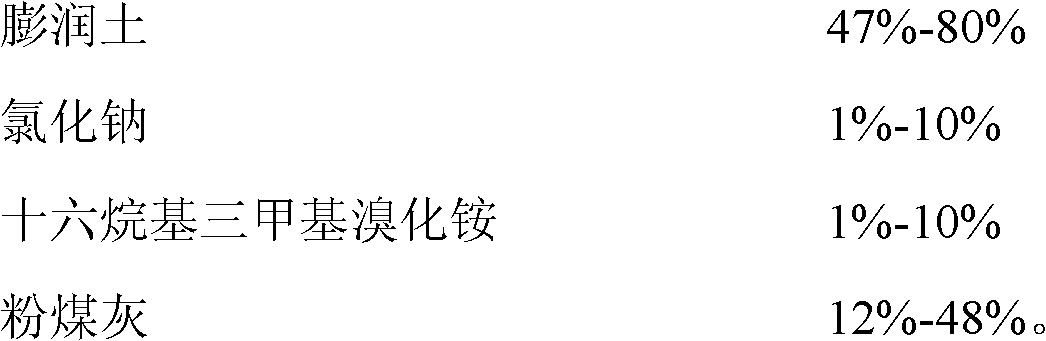

Method used

Image

Examples

Embodiment 1

[0039] The bentonite ore is crushed and passed through a 200-mesh sieve; 5.6g of sodium chloride is added to the 70g bentonite that has been crushed and sieved, stirred for 2 hours and then dried to a constant weight; the dried bentonite is crushed and then passed through a 200-mesh sieve, and added 6.4g cetyltrimethylammonium bromide was stirred for 4 hours; 18g fly ash was added and stirring continued for 3 hours to obtain a mixture; the obtained mixture was filtered and washed to neutral (pH=6.5-7.5 ), dry to obtain a mixture to prepare an adsorbent; put the obtained adsorbent into a water containing four antibiotics of tetracycline, oxytetracycline, sulfadiazine and chloramphenicol at 10-20g / L, stir for 20-30min, and precipitate . Under these conditions, the adsorption efficiency of tetracycline with an initial concentration of 100 ppm is 94.5%, oxytetracycline is 92.1%, sulfadiazine is 94.0%, and chloramphenicol is 94.4%.

Embodiment 2

[0041] Crush the bentonite ore and pass it through a 200-mesh sieve; add 6g of sodium chloride to the 50g bentonite that has been crushed and sieved, stir for 2 hours and then dry to a constant weight; crush the dried bentonite through a 200-mesh sieve and add 6g Cetyltrimethylammonium bromide was stirred for 4 hours; 38g of fly ash was added, and stirring was continued for 3 hours to obtain a mixture; the obtained mixture was filtered and washed to neutrality (pH=6.5-7.5), After drying, the mixture is obtained, and the adsorbent is prepared; the adsorbent is poured into a water containing four antibiotics of tetracycline, oxytetracycline, sulfadiazine and chloramphenicol at 10-20g / L, and stirred for 20-30min to precipitate. Under these conditions, the adsorption efficiency of tetracycline with an initial concentration of 100 ppm is 97%, oxytetracycline is 98%, sulfadiazine is 93.2%, and chloramphenicol is 92.4%.

Embodiment 3

[0043] The bentonite ore is crushed and passed through a 200-mesh sieve; 3g of sodium chloride is added to the crushed and sieved 47g bentonite, stirred for 2 hours and then dried to a constant weight; the dried bentonite is crushed and then passed through a 200-mesh sieve, and 4g is added Cetyltrimethylammonium bromide was stirred for 4 hours; 46 g of fly ash was added, and stirring was continued for 3 hours to obtain a mixture; the obtained mixture was filtered and washed until neutral (pH=6.5-7.5), After drying, the mixture is obtained, and the adsorbent is prepared; the adsorbent is put into the water containing tetracycline, oxytetracycline, sulfadiazine, and chloramphenicol at 10-20g / L, and stirred for 20-30min to precipitate. Under this condition, the adsorption efficiency of tetracycline with an initial concentration of 100 ppm is 91.0%, oxytetracycline is 93.1%, sulfadiazine is 95.2%, and chloramphenicol is 89.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com