Apparatus and method used for synthesizing zinc germanium diphosphide polycrystalline

A synthesis device and synthesis method technology, applied in the direction of zinc compounds, germanium compounds, chemical instruments and methods, etc., can solve problems such as difficult to meet one-time synthesis, explosion, etc., and achieve easy operation, simple batching and feeding process, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

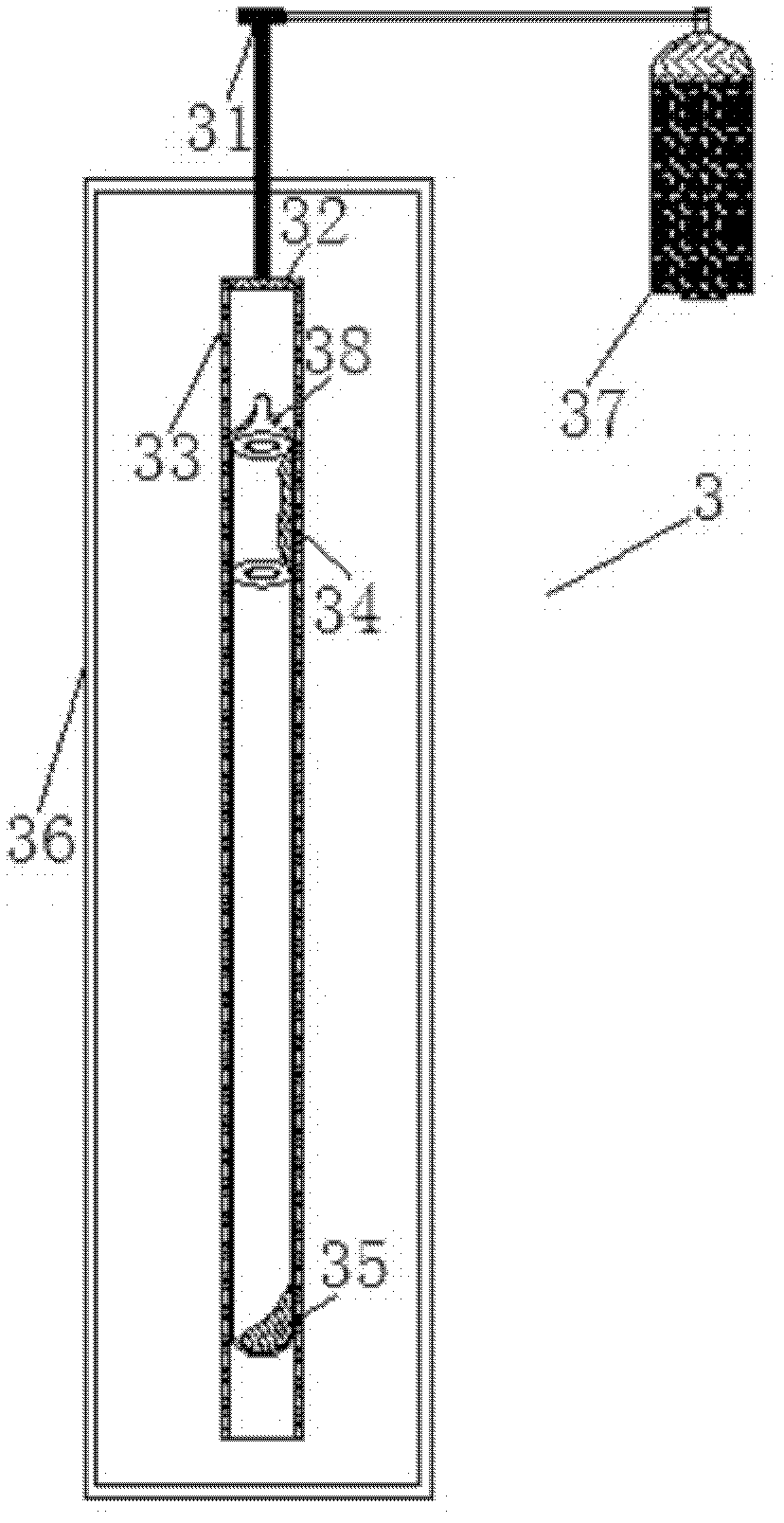

[0041] Such as figure 1 As shown, a synthesis device for phosphorus-germanium-zinc polycrystals includes a crucible 1 , a heating furnace 3 , and a motor 37 . The heating furnace 3 is provided with a furnace shell 36, which is provided with an explosion-proof steel pipe 33, and the crucible 1 is arranged in the explosion-proof steel pipe 33, and the explosion-proof steel pipe 33 is connected with a motor 37 through a linkage rod 31. The heating furnace 3 is a horizontal furnace with eight temperature zones. An explosion-proof steel pipe 33 is arranged in the horizontal furnace with eight temperature zones. The nozzle of the explosion-proof steel pipe 33 is provided with a steel sheet bayonet 32, and the steel sheet bayonet 32 is connected to the motor 37 through a linkage rod 31. . Among them, 34 is a mixture of zinc and germanium; 35 is phosphorus.

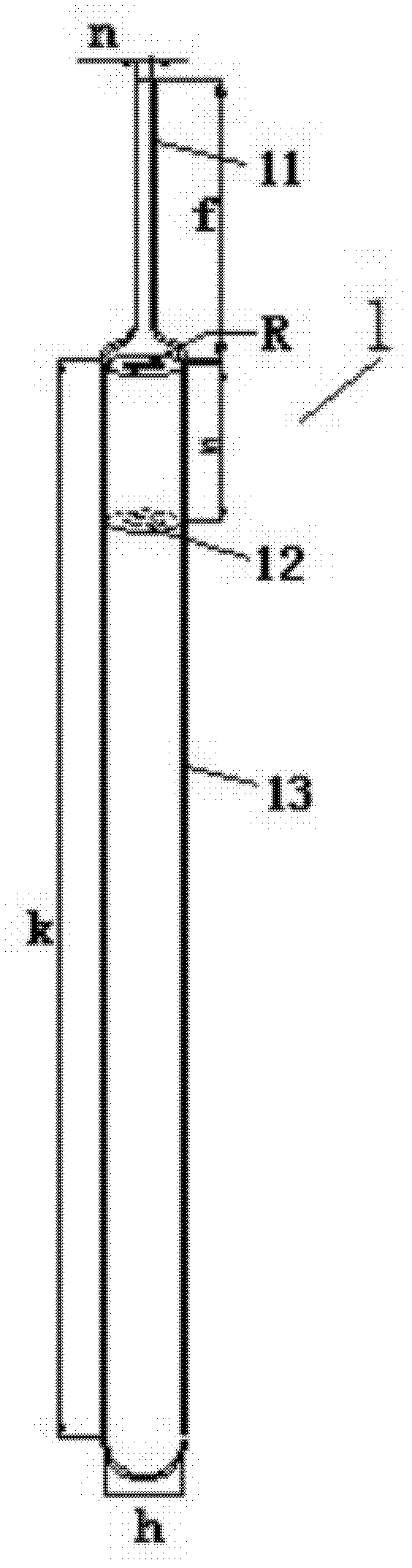

[0042] Such as image 3 As shown, the crucible 1 includes a sealing tube 11 , a cylinder 12 and a transport tube 13 connect...

Embodiment 2

[0066] This embodiment is except following feature, and other features are all identical with embodiment 1: as Figure 7 Shown is the X-ray powder diffraction pattern of the present embodiment; In this embodiment, for the growth of the phosphorus-germanium-zinc polycrystal with a total weight of 150g, the specific operation is as follows:

[0067] (1) Loading and packaging

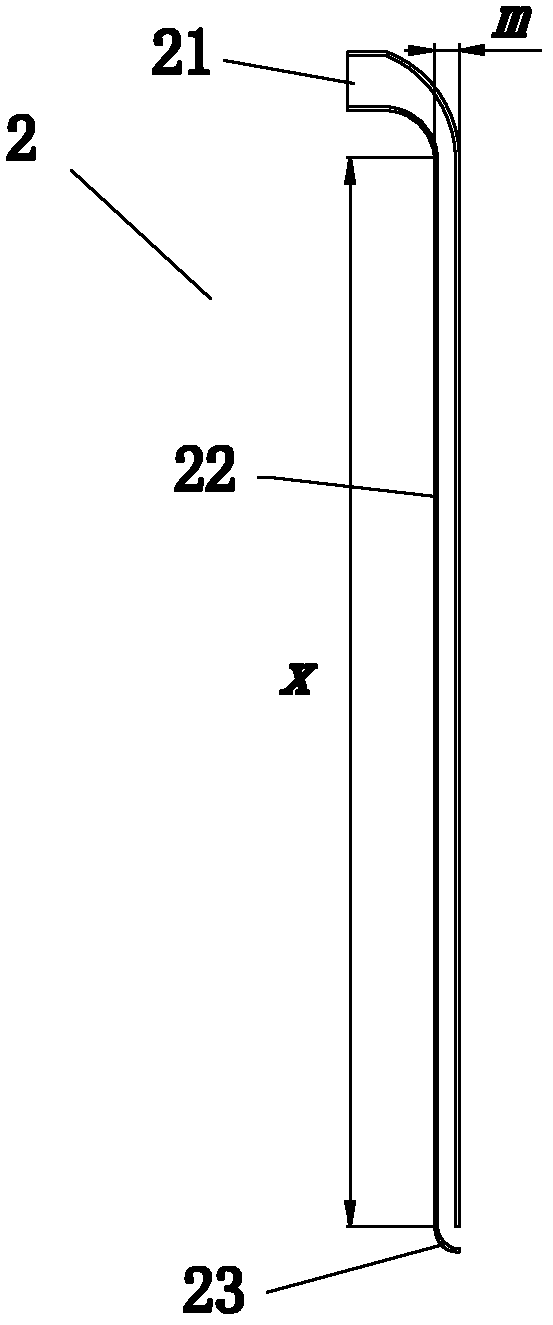

[0068] According to the stoichiometric ratio of phosphorus: germanium: zinc = 1:1:2, weigh the raw materials; fully mix the zinc and germanium; first put the phosphorus into the bottom of the crucible 1 through the auxiliary charging pipe 2, and then put the zinc and germanium into the bottom of the crucible 1 The mixture is loaded into the cylinder 12 in the crucible 1 through the auxiliary charging pipe 2, and the above process is all completed in the glove box; finally, the crucible 1 is taken out from the glove box, and the crucible is evacuated to 10 -4 Pa sealed;

[0069] (2) Crucible rotation assi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com