A Liuweidihuang nano-microcapsule and its preparation process

A technology of Liuwei Rehmannia glutinosa and preparation process, which is applied in the directions of microcapsules, nanocapsules, antidote, etc., can solve the problems of large dosage, inconvenience, and inappropriate preparation of polysaccharides, and achieves short technological process, simple operation, and increased dissolution rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

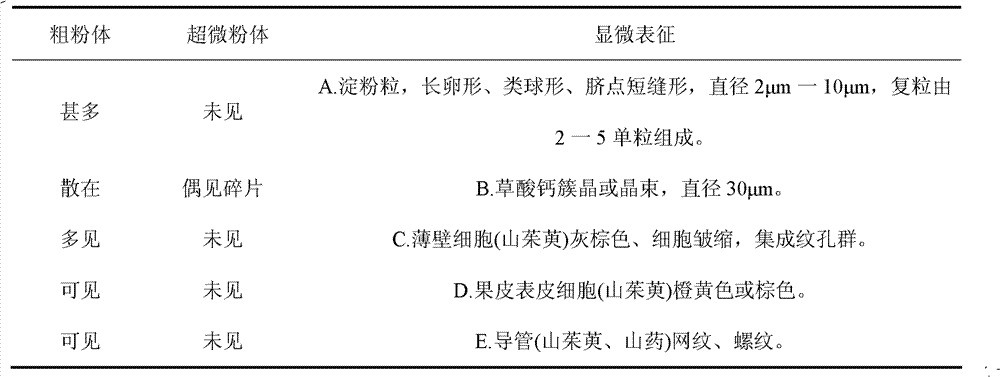

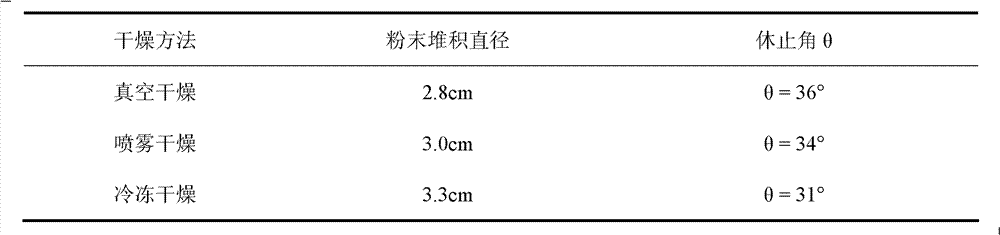

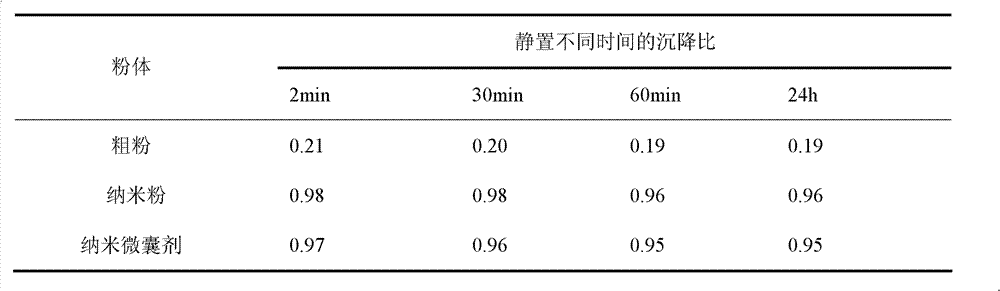

[0046] Add 1408 grams of Rehmannia glutinosa, 528 grams of Poria cocos, and 538 grams of Alisma, add 10 L of water and put it into the hot reflux extraction and concentration equipment, T=90°C-95°C, reflux extraction for 3-4 hours, filter the extract, and set aside. 704 grams of Cornus officinalis, 528 grams of Cortex Moutan, and 704 grams of Chinese yam are conventionally crushed, and after passing through an 80-mesh sieve, they are put into a superfine pulverizer for superfine or nanoscale pulverization. The spindle speed is 300r / min-350r / min. Sieve above 1250 mesh, set aside. The above extract and nano-scale fine powder are uniformly mixed at a ratio of 0.5:1 to a paste and set aside. Pre-cool the Liuweidihuang nano suspension at -20°C for 30 minutes, put it into a freeze vacuum dryer, set the cold trap temperature at -50°C to 40°C, and vacuum at 90-120Pa, and dry for 6h-12h. The dried sample is pulverized, ground and sieved to obtain Liuwei Dihuang nano-microcapsules. wo...

Embodiment 2

[0048] Add 1408 grams of Rehmannia glutinosa, 528 grams of Poria cocos, and 538 grams of Alisma, add 10 L of water and put it into the hot reflux extraction and concentration equipment, T=96°C-98°C, reflux extraction for 2 hours, filter the extract, and set aside. 704 grams of dogwood, 528 grams of peony cortex, and 704 grams of yam are conventionally crushed, passed through an 80-mesh sieve, and put into a superfine pulverizer for nano-scale crushing. The spindle speed is 350r / min-400r / min. Sieve, set aside. The above extract and nano-scale fine powder are uniformly mixed at a ratio of 1:0.5 to a suspension or paste, and set aside. Pre-cool the above-mentioned Liuwei Dihuang nano-suspension at -20°C for 24 hours, put it into a freeze-vacuum dryer, set the temperature of the cold trap at -50°C--40°C, and dry it for 20h-24h at a vacuum degree of 7.90-30.20Pa. After crushing, grinding and sieving, Liuwei Dihuang nano-microcapsules are obtained. Works best.

Embodiment 3

[0050] Add 1408 grams of Rehmannia glutinosa, 528 grams of Poria cocos, and 538 grams of Alisma, add 10 L of water and put it into the hot reflux extraction and concentration equipment, T=98°C-100°C, reflux extraction for 1 hour, filter the extract, and set aside. 704 grams of dogwood, 528 grams of peony bark, and 704 grams of Chinese yam are conventionally crushed, passed through an 80-mesh sieve, and put into a superfine pulverizer for nano-scale crushing. The spindle speed is 400r / min-450r / min. Sieve, set aside. The above extract and nano-scale fine powder are uniformly mixed at a ratio of 20:1 to form a suspension and set aside. Pre-cool the above-mentioned Liuwei Dihuang nano suspension at -20°C for 4 hours, put it into a freeze-vacuum dryer, set the temperature of the cold trap at -50°C-40°C, and vacuum degree of 60-80Pa, dry it for 6h-24h, and dry the dried sample After crushing, grinding and sieving, Liuwei Dihuang nano-microcapsules are obtained. works well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com