Reverse osmosis composite membrane and preparation method thereof

A reverse osmosis composite membrane and mesoporous technology, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of limited stability of inorganic nanoparticles and achieve the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

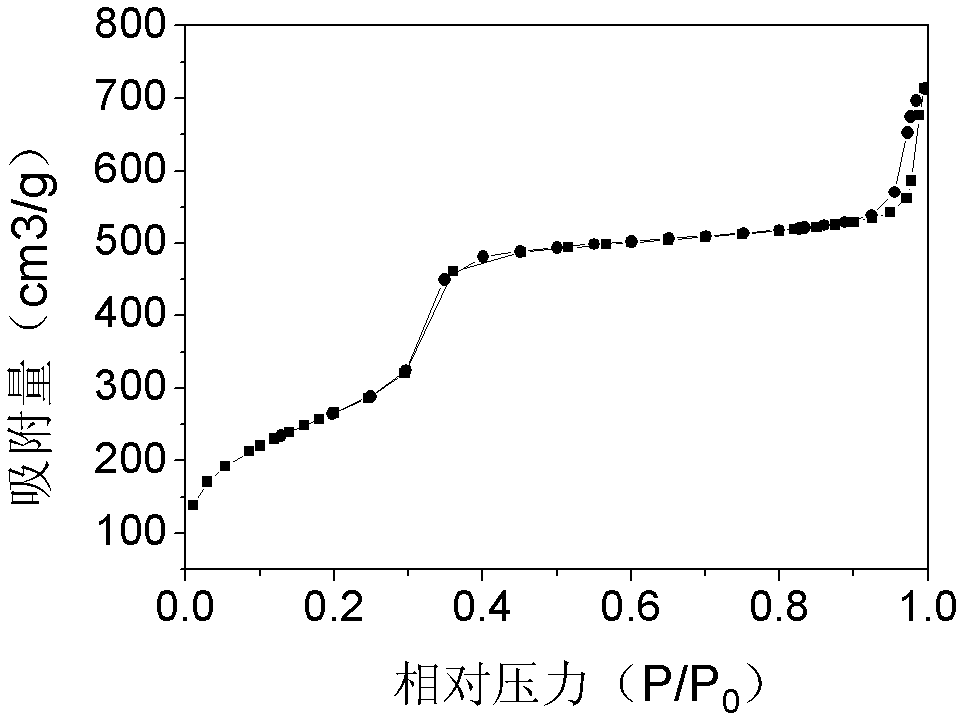

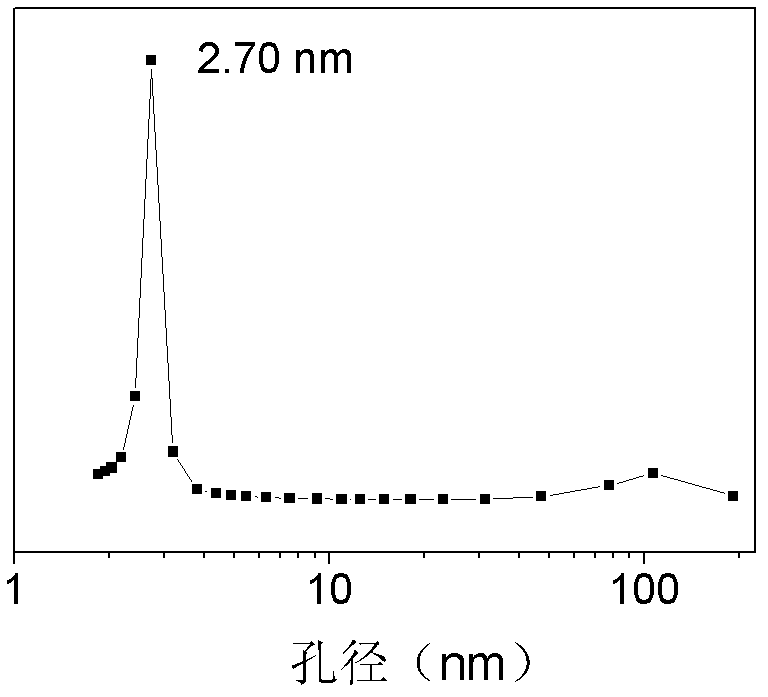

[0028] Example 1 Monodisperse spherical amino-functionalized mesoporous SiO 2 Preparation of nanoparticles

[0029] Amino-functionalized mesoporous SiO with 10% 3-aminopropyltriethoxysilane content in the initial reaction solution 2 Preparation of molecular sieve: Dissolve 0.2000g cetyltrimethylammonium bromide (CTAB) in 86.4ml deionized water, add 9.6ml ethanol and 0.7ml concentration of sodium hydroxide that is 2mol / L, and vigorously Stir until the solution is clear and transparent, then quickly add a mixture of 1.15ml tetraethyl orthosilicate and 0.1268g 3-aminopropyltriethoxysilane under stirring, and continue vigorously stirring for 2 hours. The reaction mixture was successively filtered, washed with ethanol three times, and dried under vacuum at 60° C. for 12 hours. The template agent was removed by solvent extraction. In a 100mL Erlenmeyer flask, add the dried material containing the template agent, 30mL absolute ethanol and 5ml concentrated hydrochloric acid (HCl36-3...

Embodiment 2

[0030] Example 2 Monodisperse spherical amino-functionalized mesoporous SiO 2 Preparation of nanoparticles

[0031] Amino-functionalized mesoporous SiO with 20% 3-aminopropyltriethoxysilane content in the initial reaction solution 2 Preparation of molecular sieves: Dissolve 0.2000g cetyltrimethylammonium bromide (CTAB) in 86.4ml deionized water, add 9.6ml ethanol and 0.7ml 2mol / L sodium hydroxide, stir vigorously at 80°C until solution Clear and transparent, the mixture of 1.02ml tetraethyl orthosilicate and 0.2536g 3-aminopropyltriethoxysilane was added rapidly under stirring, and the vigorous stirring was continued for 2 hours. The reaction mixture was successively filtered, washed with ethanol three times, and dried under vacuum at 60° C. for 12 hours. The template agent was removed by solvent extraction. In a 100mL Erlenmeyer flask, add the dried material containing the template agent, 30mL absolute ethanol and 5ml concentrated hydrochloric acid (HCl36-38%), stir at 50°C...

Embodiment 3

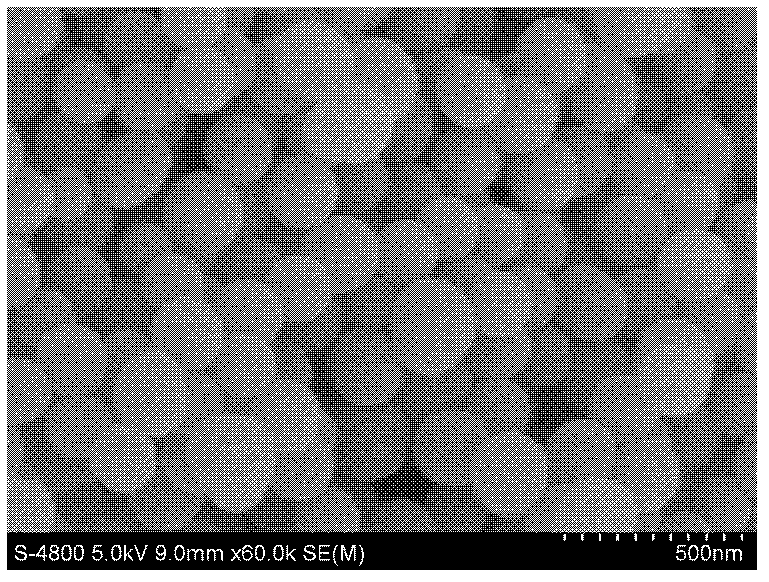

[0033] The preparation of embodiment 3 reverse osmosis composite membranes

[0034] Amino-functionalized mesoporous SiO with a mass fraction of 0.05% (w / v) 2 Molecular sieves were dispersed into the oil phase by ultrasound (sonication for 1h at room temperature). Immerse the wet polysulfone base membrane into the m-phenylenediamine solution (water phase) with a mass volume ratio concentration g / ml of 2%, and roll it with a rubber rod to make the water phase fully interact with the supporting membrane, and drain the water phase After (draining time is about 150s), with dispersed amino-functionalized mesoporous SiO 2 The n-hexane solution of trimesoyl chloride (TMC) of the molecular sieve is contacted for interfacial polymerization reaction, dried in the air for 2 minutes, and then heat-treated at 110-120° C. for 3 minutes to prepare a molecular sieve / polyamide reverse osmosis composite membrane. like Figure 5 As shown, the scanning electron micrographs show that the amino-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com