Aqueous polyaniline and preparation method thereof

A water-based polyaniline and aniline technology, applied in the field of polymer materials, can solve problems such as being unable to meet the needs of environmental friendliness, small specific surface area of products, and need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The embodiment of the invention discloses a preparation method of water-based polyaniline, comprising:

[0041] Add aniline into the doping acid solution, and configure an aniline salt solution with a concentration of 1mol / L to 3mol / L, and the doping acid is a phosphate ester containing an ethoxy group or a sulfonate ester containing an ethoxy group ;

[0042] Dissolving the oxidizing agent in water and preparing an oxidizing agent solution with a concentration of 1mol / L to 3mol / L, the oxidizing agent is ferric nitrate, ferric chloride, ferric sulfate or copper chloride;

[0043] At 0°C to 5°C, the aniline salt solution and the oxidant solution were added dropwise and mixed at a constant speed according to the molar ratio of the aniline to the oxidant being 1: (1.2 to 15), and the mixed solution was mixed at -30°C to 10°C Stand still at ℃ to obtain water-based polyaniline.

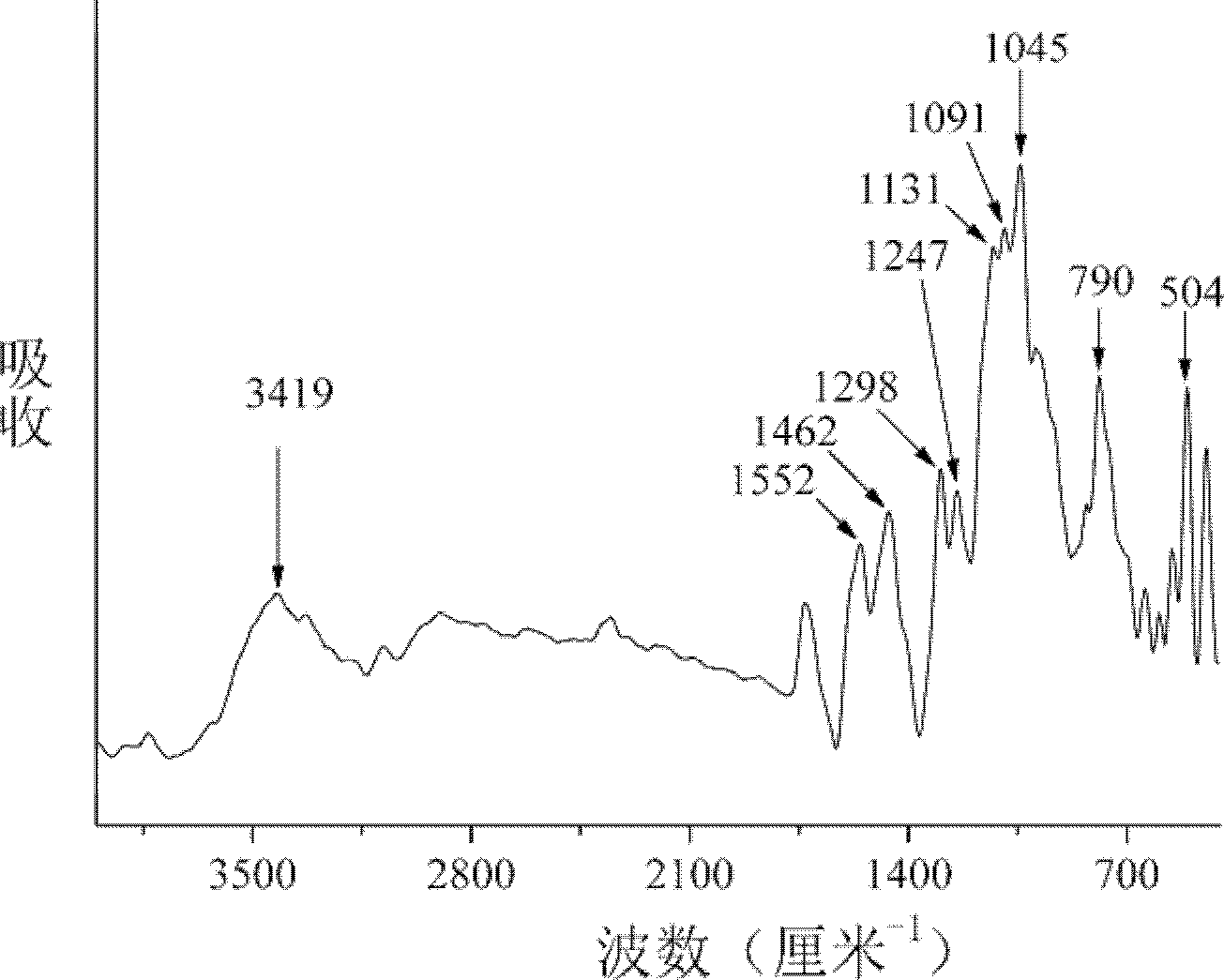

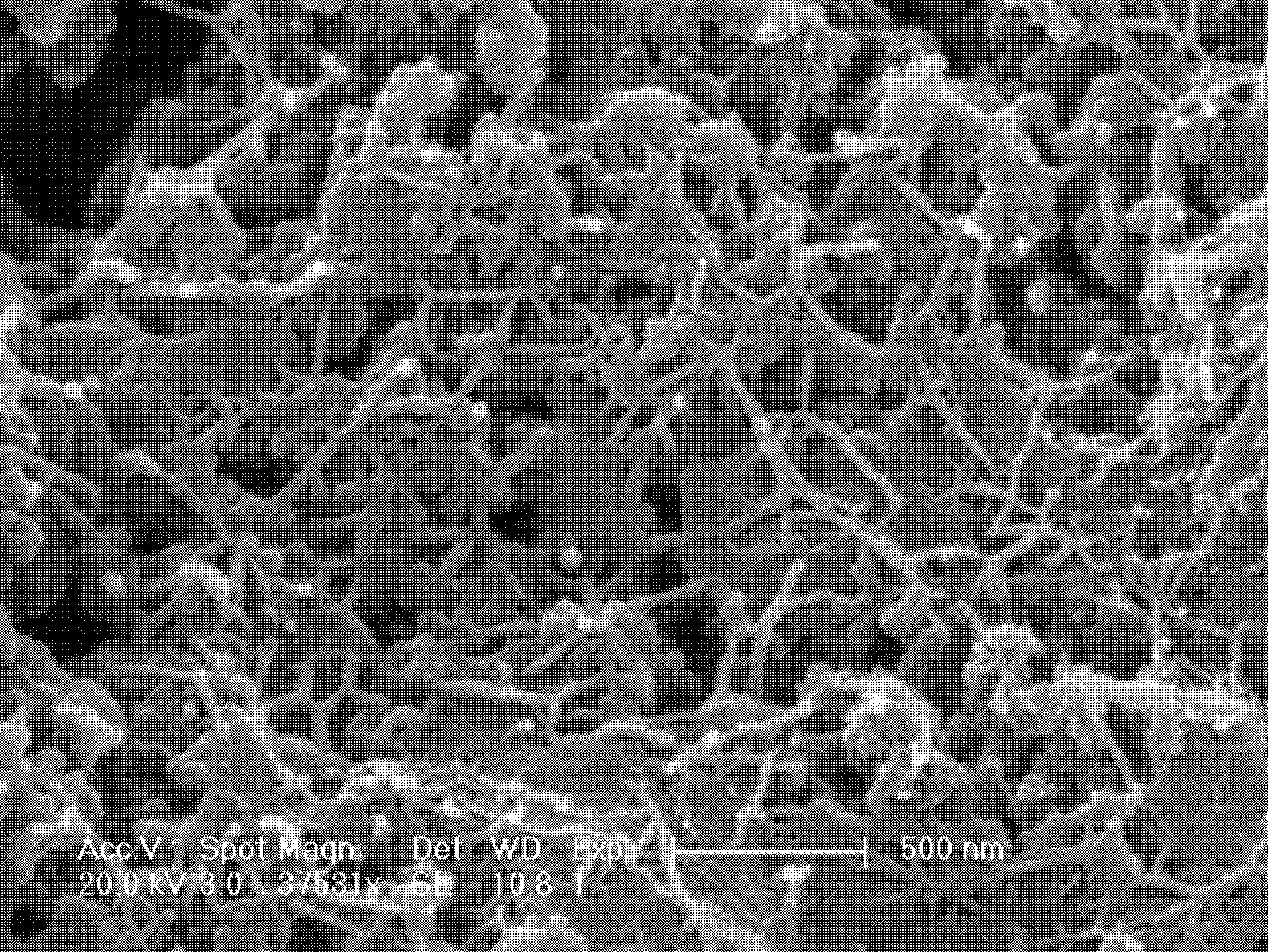

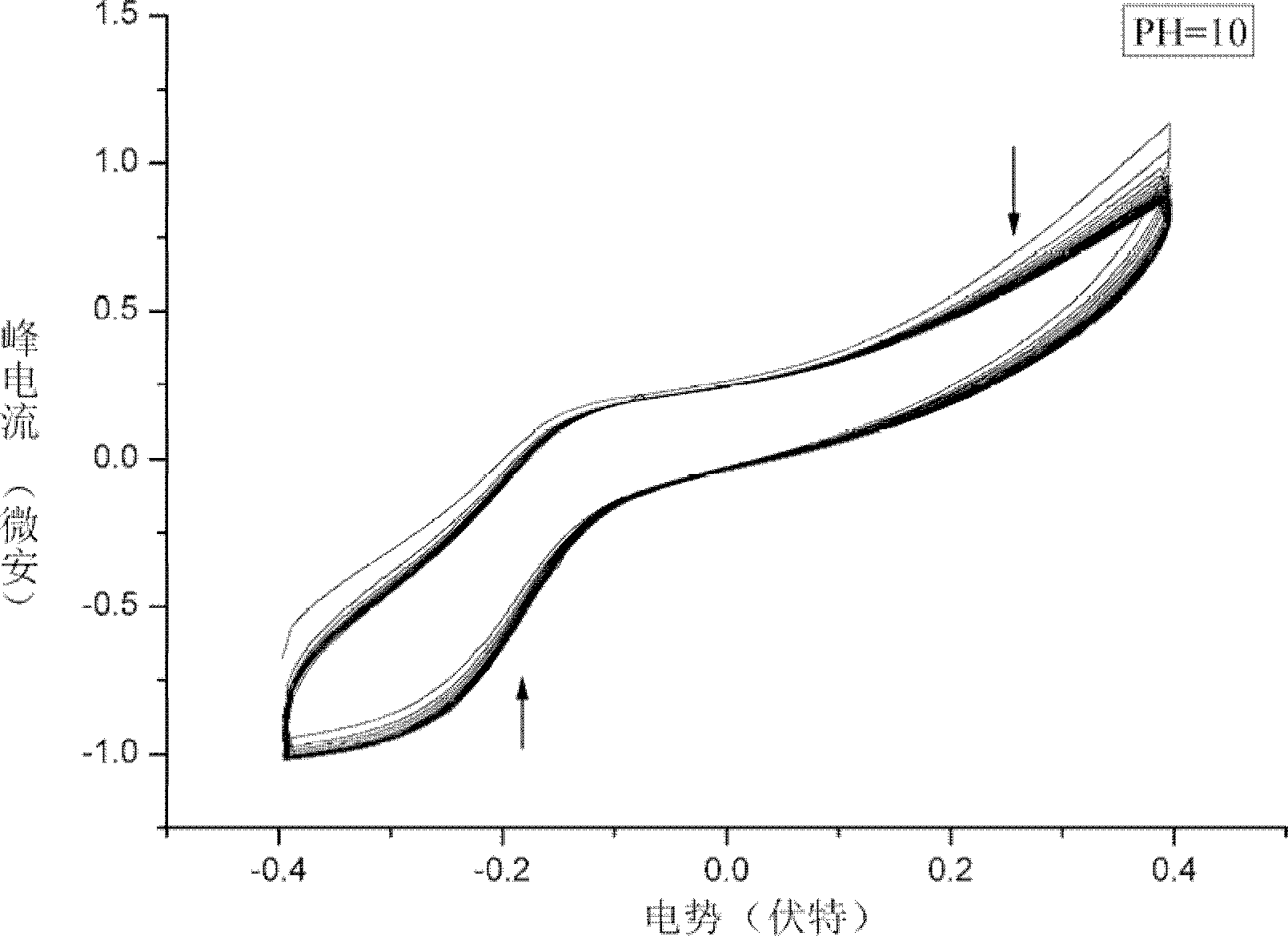

[0044] In order to improve the hydrophilicity of polyaniline and prepare water-based polyanili...

Embodiment 1

[0077] Step 1, under stirring condition, dissolve aniline monomer in 1mol / L doping acid solution, make the aniline salt aqueous solution that molar concentration is 1mol / L, doping acid has structural formula (I), m in formula (I) = 1;

[0078] Formula (I)

[0079] Step 2, under stirring conditions, ferric nitrate is dissolved in deionized water to form a 1mol / L ferric nitrate aqueous solution;

[0080] Step 3, by the molar ratio of substance is aniline: ferric nitrate=1: 3, at 0~5 ℃, the doping acid solution that step 1 obtains and the ferric nitrate solution that step 2 obtains with the speed of 35~50mL / min Add it dropwise into the reactor, after the dropwise addition is completed, stop stirring, keep the temperature at 0-5°C, and let it stand still for 24 hours;

[0081] Step 4, after filtering the reaction product obtained in step 3, wash with deionized water and methanol respectively until the filtrate is colorless;

[0082] Step 5, vacuum drying the product obtained ...

Embodiment 2

[0088] Step 1. Under stirring conditions, dissolve the aniline monomer in 1mol / L doping acid to make an aniline salt solution with a molar concentration of 1mol / L. The doping acid has the structural formula (III), and m=7 in the formula (III) ;

[0089] Formula (III)

[0090] Step 2, under stirring conditions, ferric nitrate is dissolved in deionized water to form a 1mol / L ferric nitrate aqueous solution;

[0091] Step 3, by the molar ratio of substance is aniline: ferric nitrate=1: 3, at 0~5 ℃, the doping acid solution that step 1 obtains and the ferric nitrate solution that step 2 obtains with the speed of 35~50mL / min Add it dropwise into the reactor, after the dropwise addition is completed, stop stirring, keep the temperature at 0-5°C, and let it stand still for 24 hours;

[0092] Step 4, after filtering the reaction product obtained in step 3, wash with deionized water and methanol respectively until the filtrate is colorless;

[0093] Step 5, vacuum drying the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com