Nylon nucleating agent and its preparation method and use

A nucleating agent and nucleating technology, which is applied in the field of nylon nucleating agent and its preparation, can solve the problems of decreased impact resistance of materials, ineffective nucleating effect, and increased bending strength of nylon, so as to reduce shrinkage, Effects of shortening the injection molding cycle and increasing the heat resistance temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

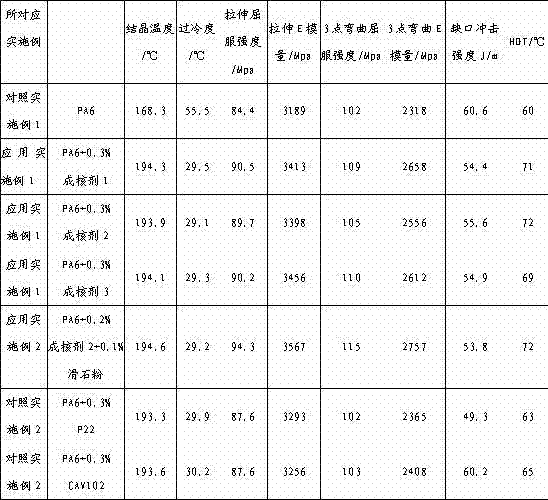

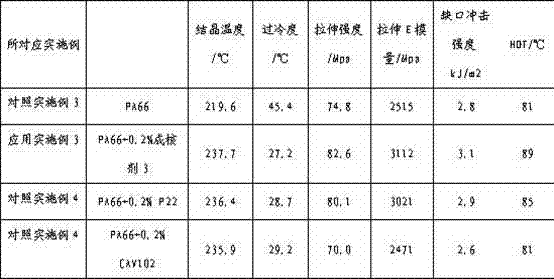

Examples

Embodiment 1

[0029] Add 25.0g MDI (99.9%, NPU from Japan) into a 250ml three-necked flask, add 150ml chloroform solvent, heat to 50°C, add 10.9g cyclohexylamine (analytical grade, Sinopharm Group) and 11.0g cyclohexanol (analytical grade , Sinopharm Group), adding catalyst 0.1ml triethylamine, stirring and reacting at 1000rpm for 2 hours. Cool to room temperature, filter, then wash the insoluble product 3 times with chloroform to remove unreacted amine and alcohol, dry it under vacuum at 60°C for 4 hours, and pulverize to obtain a white to light yellow powder, which is nylon nucleating agent 1.

Embodiment 2

[0031] Add 25.0g MDI (99.9%, Japanese NPU) into a 250ml three-neck flask, add 150ml chloroform, heat to 70°C, add 10.9g cyclohexylamine (analytical grade, Sinopharm Group) and 7.9g 1,4-cyclohexanediol (reagent grade, Shanghai Bangcheng Chemical Co., Ltd.), add 0.1ml triethylamine, stir and react at 1000rpm for 2 hours; cool to room temperature, filter, then wash the insoluble product with chloroform three times to remove unreacted amine and alcohol, Vacuum-dried at 60°C for 4 hours and pulverized to obtain a white to light yellow powder, which is nylon nucleating agent 2.

Embodiment 3

[0033] Add 17.4g TDI (99.5%, Mitsui, Japan) into a 250ml three-necked flask, add 150ml chloroform, heat to 50°C, add 10.9g cyclohexylamine (analytical grade, Sinopharm) and 11.0g cyclohexanol (analytical grade, Sinopharm Group), adding 0.1ml of triethylamine, stirring and reacting at 1000rpm for 2 hours. Cool to room temperature, filter, then wash the insoluble product three times with chloroform to remove unreacted amine and alcohol, dry it in vacuum at 60°C for 4 hours, and pulverize to obtain a white to light yellow powder, which is nylon nucleating agent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com