Tertiary treatment device of automobile exhaust and separation method thereof

A treatment device and a three-stage treatment technology, applied in the field of air pollution control, can solve problems such as low efficiency, and achieve the effects of simple structure, reduced emissions, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

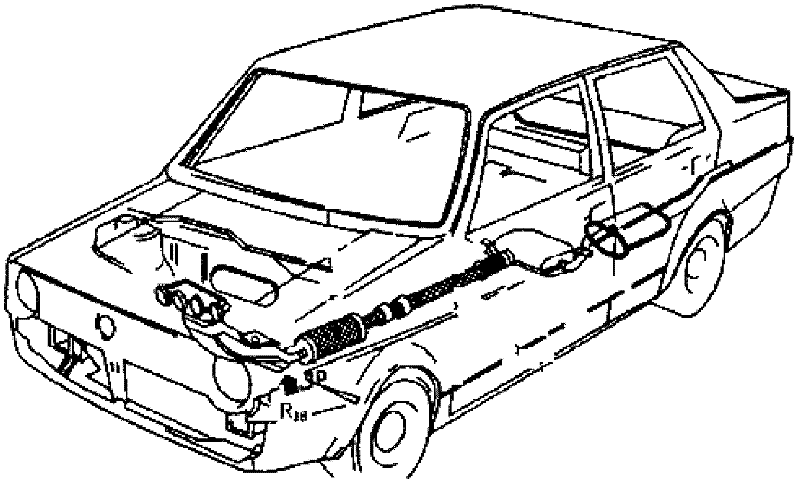

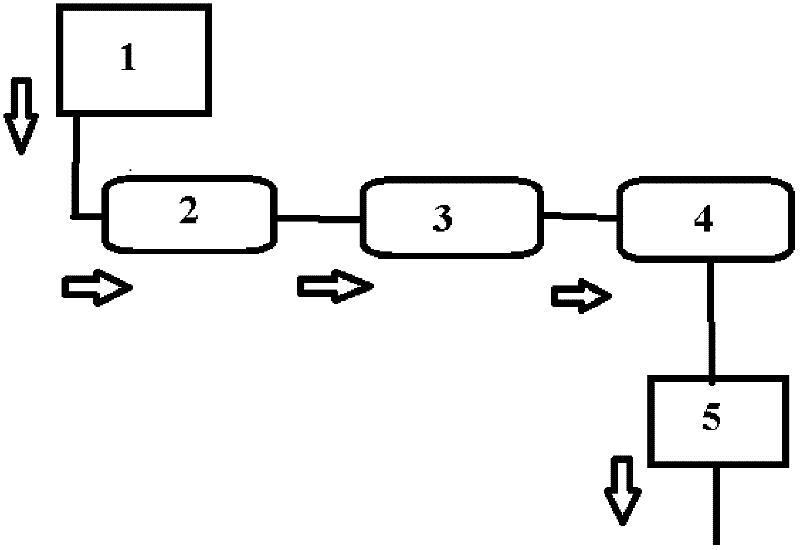

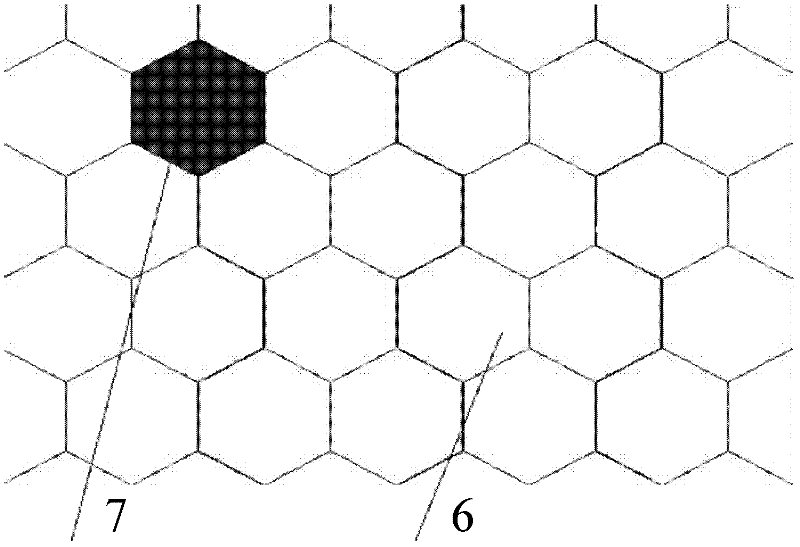

[0021] Such as figure 1 , 2 As shown, a three-stage treatment device for automobile exhaust gas is composed of a three-way catalytic converter 1, a primary primary treatment device 2, a secondary sulfur oxide nitrogen oxide treatment device 3 and a third-stage carbon dioxide treatment device 4. Wherein, the first-level primary treatment device 2 is a primary separator, and the primary separator is a honeycomb carrier structure 6 filled with activated carbon particles 7 (such as image 3 ), the honeycomb carrier and activated carbon particles form an adsorption layer for rough treatment of automobile exhaust. The secondary sulfur oxide nitrogen oxide treatment device 3 is mainly composed of photocatalytic reactors (including TiO 2Photocatalytic reaction layer 11 and ultraviolet lamp 12) consist of fan 9, pre-filter layer 10, TiO 2 Photocatalytic reaction layer 11, ultraviolet lamp 12, gas-oxygen mixing chamber 13, oxygen generator 14, anion generator 16 and other structures,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com