Uncooled infrared detector

An infrared detector and non-cooling technology, applied in the field of infrared thermal imaging, can solve the problems of increasing process flow and process steps, and achieve the effect of large optical fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

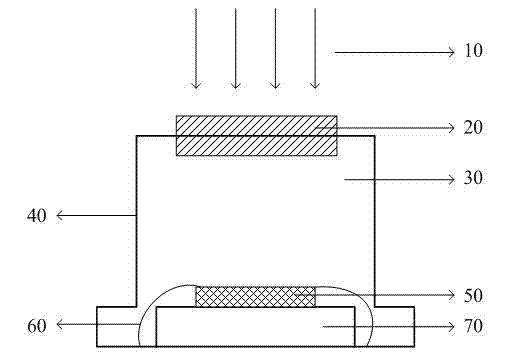

Embodiment 1

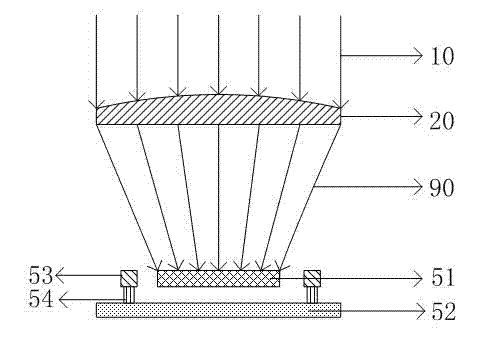

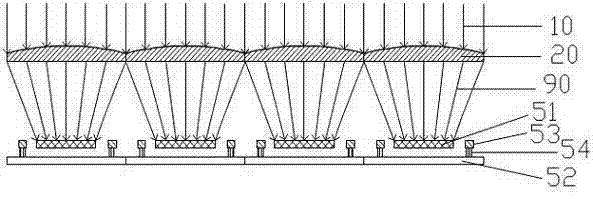

[0027] see Figure 2~Figure 3 , the infrared window 20 of the present invention is a microlens array structure with light converging effect, preferably a microlens array structure with light converging effect composed of microconvex lens units, which is directly processed by infrared window material germanium sheet, that is, directly The surface of the germanium sheet is processed into a regularly arranged microlens array structure; the processing steps are: patterning the germanium sheet by ordinary photolithography, and then corroding the germanium sheet with a mixed solution of hydrogen peroxide and sodium hydroxide. Due to the lateral corrosion, the cross-section of the figure presents an inclined slope, forming a microlens shape. After the etching is completed, the glue is removed and cleaned to form an infrared window 20 with a simple microlens structure on the surface.

[0028] The size of the microlens on the infrared window is consistent with the size of the detection...

Embodiment 2

[0033] like Figure 4 As shown, the infrared window 20 is a microlens array structure, and the units of the microlens array are composed of a substrate 21 and a microconvex lens unit film or a Fresnel lens unit film 22 of the surface microlens array structure. The substrate material is a germanium sheet, and then a ZnS film is prepared on the surface. The ZnS thin film is made into the shape of a microlens array through the methods of glue coating, photolithography, development and corrosion, and the lens array can converge the incident infrared light. In this way, an infrared window 20 with a microlens array structure is formed. The rest of the structure and manufacturing steps are the same as in Embodiment 1.

[0034] The infrared window 20 of the present invention is made of infrared-transmitting materials such as Ge, silicon, ZnSe, ZnS, GaAs, GaP, diamond, sapphire, MgF4, spinel single crystal or polycrystal, or is made of an infrared-transmitting polymer material. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com