Method for improving writing speed of floating body effect storage unit, and floating body effect storage unit

A memory cell and floating body effect technology, which is applied in the manufacture of transistors, electrical components, semiconductors/solid-state devices, etc., can solve problems such as leakage and needs to be improved, and achieve the goals of reducing leakage speed, increasing writing speed, and increasing substrate current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

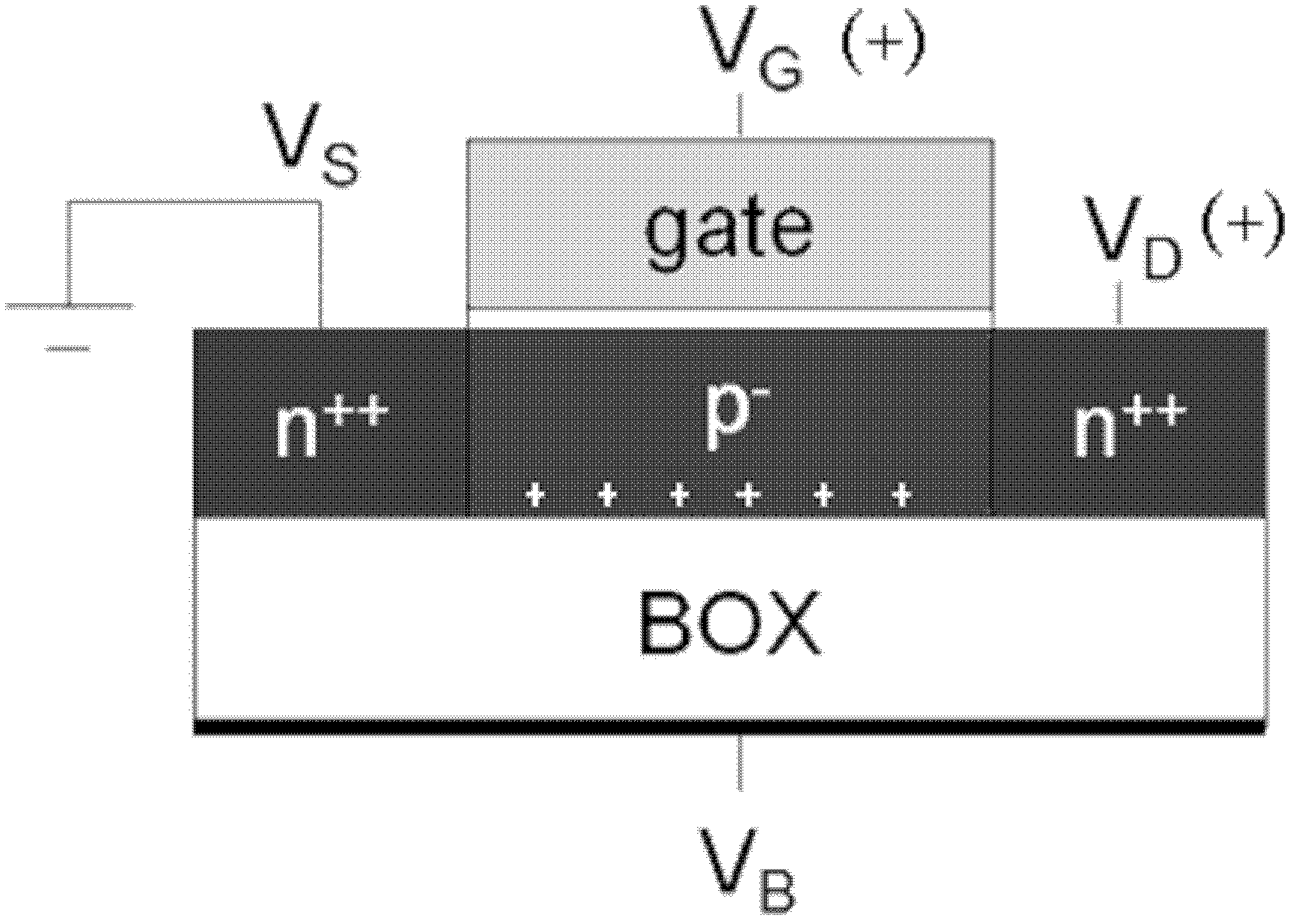

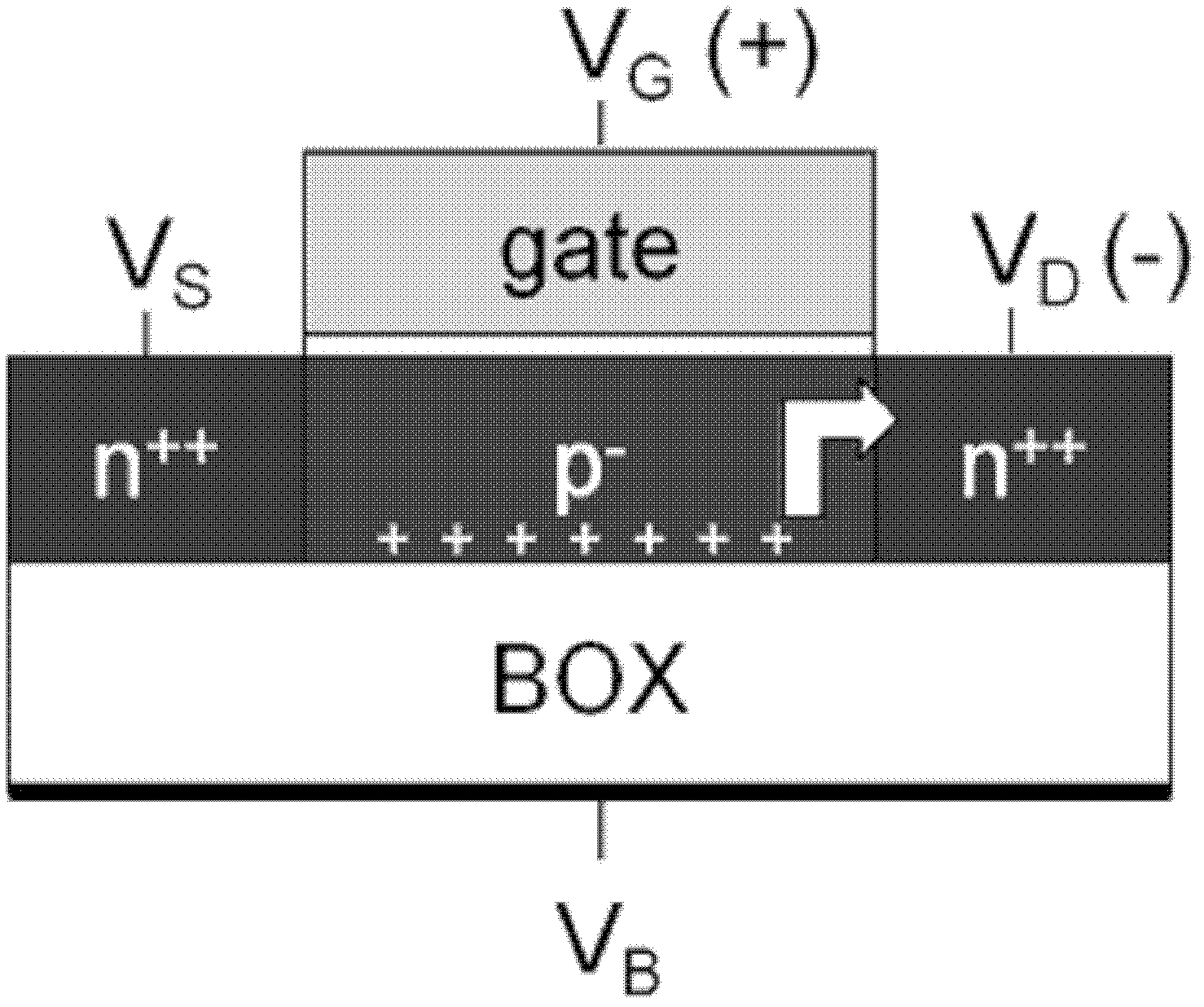

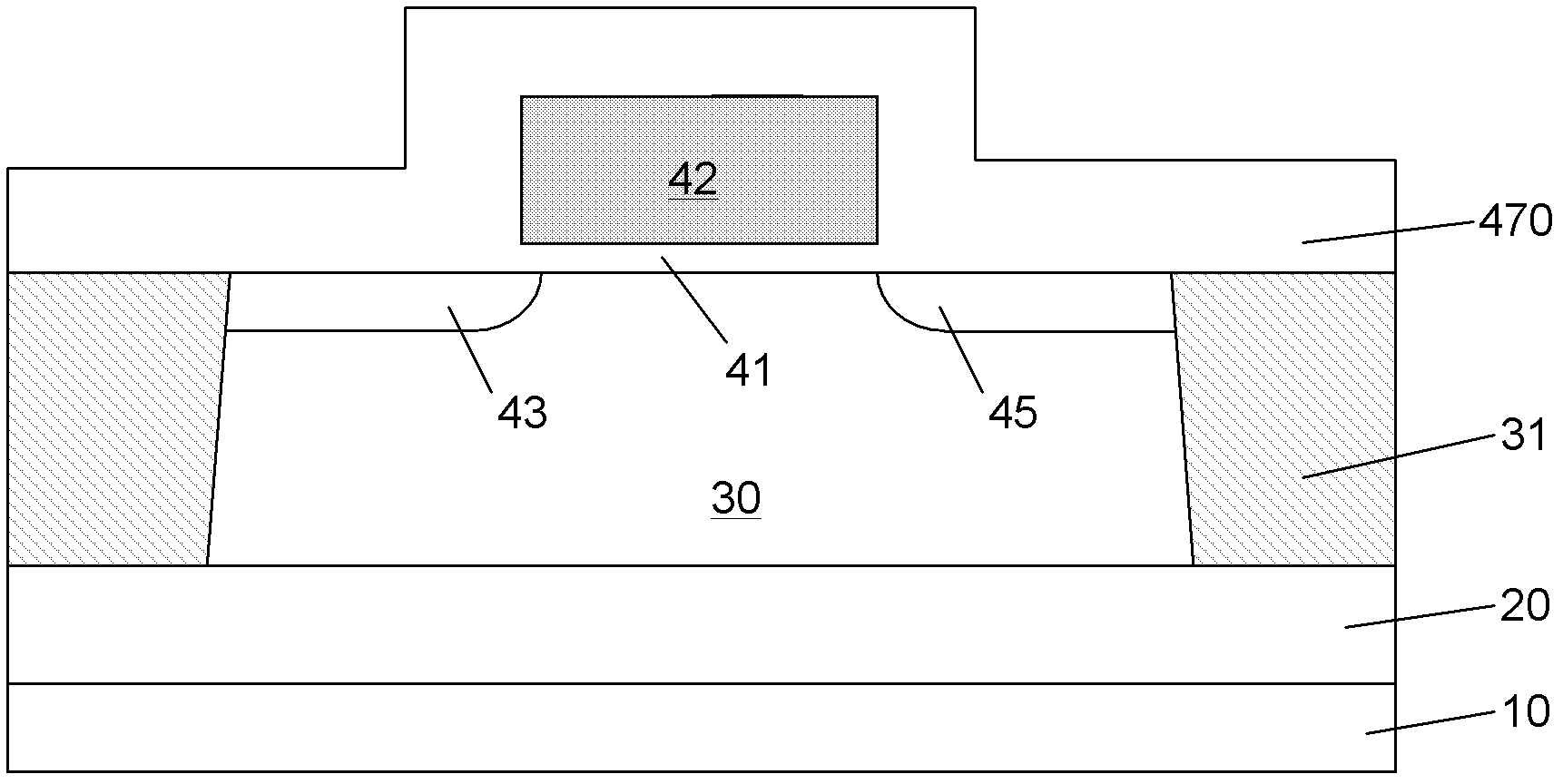

[0019] In the usual process, the sidewall formation (deposition and etching) process of the floating body effect memory cell is as follows: Figure 2A-2C shown.

[0020] First, the sidewall material is deposited, and the cross-section of the device after deposition is as follows Figure 2A shown. The floating body effect memory unit in the figure comprises bottom silicon 10, and described bottom silicon 10 is silicon-on-insulator for example; Formed on bottom silicon 10 Buried oxide layer 20; Formed on the substrate 30 of buried oxide layer 20, described The substrate 30 can be a silicon substrate, of course, in some occasions, a germanium substrate, a silicon germanium substrate or other semiconductor materials can also be applied; the shallow trench isolation groove 31 (shallow trench isolation, That is, STI), used to isolate each floating body effect memory cell; a gate oxide layer 41 and a gate 42 formed sequentially on the substrate 30, and a channel in the substrate 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com