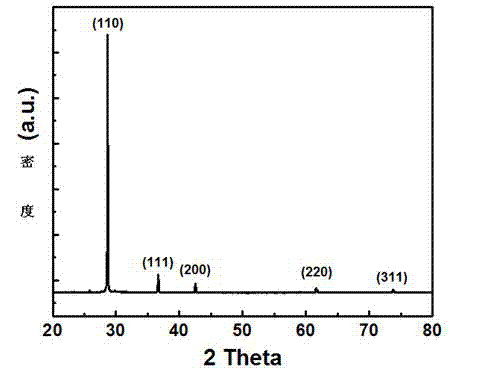

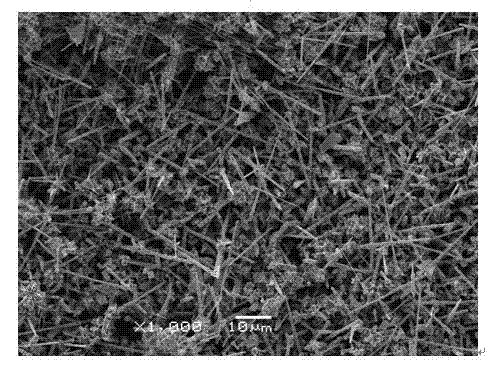

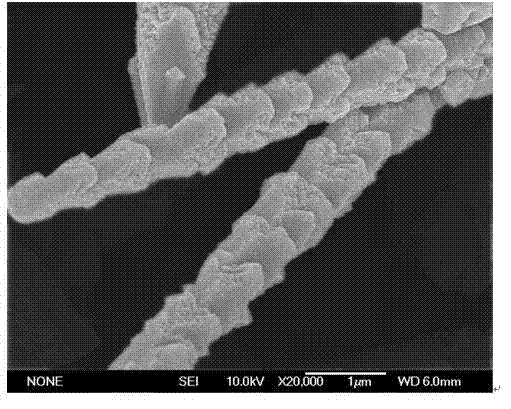

Semiconductor material with Cu2O nano bamboo shoot structure and preparation method thereof

A semiconductor and nanotechnology, applied in the field of Cu2O nanometer bamboo shoot-structured semiconductor materials and their preparation, can solve the problems of difficulty in preparing one-dimensional nanostructures, low success rate, few raw materials, etc., and achieves good adhesion, low cost, and raw materials. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention Cu 2 The preparation method of the semiconductor material of O nano shoot structure is to deposit Cu on the silicon chip 2 The preparation method of O nano shoot structure semiconductor material, comprises the steps:

[0029] a, absolute ethanol and deionized water are mixed in a certain volume ratio as a reaction solvent for use; a certain amount of Cu(CH 3 COO) 2 ·H 2 O and a small amount of pyrrole are added in the above solvent and stirred evenly to obtain the reaction solution;

[0030] b. Take a small piece of cleaned silicon wafer and put it into the bottom of the inner tank of the reaction kettle, and slowly add the above prepared reaction solution;

[0031] c. Put the sealed reaction kettle in a heating furnace heated to 180°C in advance to react for a period of time. The reaction temperature range of the preparation method of the present invention is 160-190°C.

[0032] d, after the reaction is over, take out the silicon chip covere...

Embodiment 1

[0036] 1. Clean the silicon wafer, and then cut it into small pieces of about 5mm×5mm;

[0037] 2. Set the temperature of the heating furnace to 180°C;

[0038] 3. Mix anhydrous ethanol and deionized water according to the volume ratio of 1:3 and stir evenly as a solvent for later use;

[0039] 4. Add Cu(CH 3 COO) 2 ·H 2 O powder was added to 100mL of the above-mentioned mixed solvent of absolute ethanol and deionized water to prepare Cu(CH 3 COO) 2 ·H 2 O content is the mixed solution of 25mM; Cu(CH 3 COO) 2 ·H 2 The O content allows an error of up and down 2.5mM, which has no effect on the reaction result;

[0040] 5. After stirring for about 5 minutes, add pyrrole dropwise to the above solution while stirring, Cu(CH 3 COO) 2 ·H 2 The molar ratio of O powder to pyrrole is 2:7, and the prepared reaction solution is light blue;

[0041] 6. Clean the Teflon reactor with a capacity of 100mL, place the cleaned silicon wafer horizontally on the bottom of the inner tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com