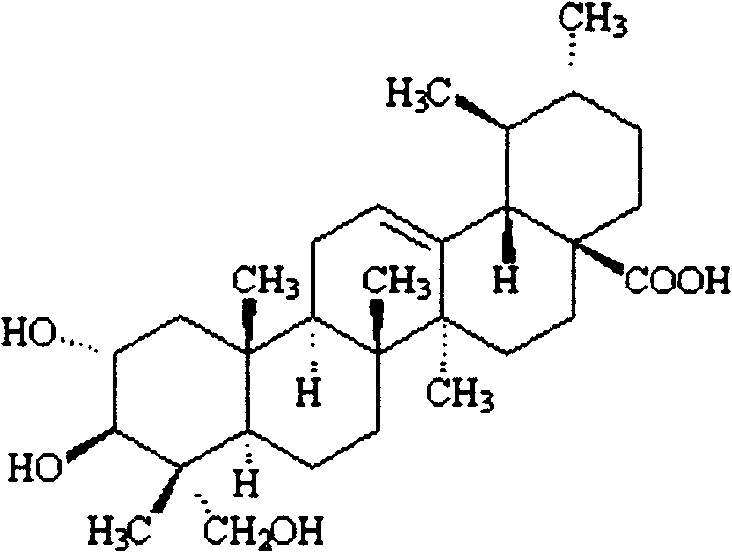

Method for purifying asiatic acid in asiatic pennywort herb

A technology of asiatic acid and centella asiatica, which is applied in the field of enzymatic extraction and macroporous resin purification of asiatic acid, can solve the problems of low extraction rate, low content, long extraction time, etc., achieve mild conditions and reduce pollution , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take Centella asiatica and crush it to 60 mesh, weigh 1kg, add appropriate amount of hydrochloric acid aqueous solution (pH5) to moisten, add 10g of cellulase, mix well, and naturally enzymatically hydrolyze for 3 days, then use 7L of 90% ethanol solution to reflux extract the raw material for enzymolysis for 1 hour , extracted 3 times, the extract was filtered to recover ethanol under reduced pressure, added 2L petroleum ether to shake, transferred to a separatory funnel, removed the petroleum ether layer, released and centrifuged to obtain 53g of crude extract, dissolved in absolute ethanol, filtered, and added 50g of NKA to the filtrate -2 macroporous resin resins, recycle ethanol. Take 50g of NKA-2 macroporous resin to pack into a column, add the dry sample to the upper part of the resin column, take 1.5L of 40% ethanol solution to elute the impurities, and then take 2L of 90% ethanol solution to elute the active ingredients, recover under reduced pressure to 40% eth...

Embodiment 2

[0024] Take centella asiatica and crush it to 10 meshes, weigh 1kg, add appropriate amount of sulfuric acid aqueous solution (pH6) to moisten, add 4g of β-glucomerase and mix well, natural enzymolysis for 5 days, enzymolysis raw materials are extracted with 10L of 70% methanol solution under reflux 2 hours, extracted twice, the extract was filtered to recover ethanol under reduced pressure, added 3L petroleum ether to shake, transferred to a separatory funnel, removed the petroleum ether layer, released and centrifuged to obtain 65g of crude extract, dissolved in absolute ethanol, filtered, and the filtrate Add 70g of NKA-9 macroporous resin to recover ethanol. Take 50g of NKA-9 macroporous resin and put it into a column, add the dry sample to the upper part of the resin column, take 4L of 20% ethanol solution to elute the impurities, then take 3L of 70% ethanol solution to elute the active ingredients, recover under reduced pressure to 30% ethanol, place for crystallization, a...

Embodiment 3

[0026] Take centella asiatica and crush it to 40 mesh, weigh 1kg, add appropriate amount of citric acid aqueous solution (pH4) to moisten, add 8g of amylase and mix well, and naturally enzymatically hydrolyze for 4 days. , the extract is filtered to recover ethanol under reduced pressure, add 1L of petroleum ether to shake, transfer to a separatory funnel, remove the petroleum ether layer, release and centrifuge to obtain 45g of crude extract, dissolve with absolute ethanol, filter, add 50g X-5 large to the filtrate Hole resin resin, recovery ethanol. Take 50g of X-5 macroporous resin to pack into a column, put the dry sample into the upper part of the resin column, take 3L of 30% ethanol solution to elute impurities, and then take 2.5L of 80% ethanol solution to elute active ingredients, recover under reduced pressure to 40% ethanol, place for crystallization, Filtrate to obtain 12 g of crystals, dissolve the crystals under reflux with anhydrous methanol, let the crystals sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com