Method for preparing polycarboxylic acid water reducing agent

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of preparing high-concentration polycarboxylate water-reducing agent, and can solve the problem of inability to prepare high-concentration polycarboxylic acid water-reducing agent and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] First add MPEG600 (methoxypolyethylene glycol 600, which is liquid at room temperature): 600g and 98g of maleic anhydride to the four-necked flask, and raise the temperature to 118°C-122°C, and perform esterification reaction under nitrogen protection for 4-6 hours. To synthesize polyethylene glycol monomethyl ether monomaleic anhydride ester, add 1.125g of thioglycolic acid when the temperature drops below 50°C, and start adding styrene and initiator azobisisobutyronitrile dropwise when the temperature rises to 58°C-62°C The mixture consists of 52g styrene and 3.75g initiator azobisisobutyronitrile, and the mixture accounts for 5-10% of the total mass of the finished product. The mixture of styrene and azobisisobutyronitrile was dropped in 3.0 hours. After the drop was completed, the reaction was kept for 2 hours. When the temperature dropped below 30°C, 153g of 32% liquid caustic soda was added, and finally 77g of water was added to obtain a solid content of 80 % poly...

Embodiment 2

[0017] First add MPEG600: 600g and 147g maleic anhydride to a four-neck flask and raise the temperature to 118°C-122°C. For example, when heated to 122°C, esterify for 4-6 hours under the protection of nitrogen to synthesize polyethylene glycol monomethyl ether monomaline To acid anhydride ester, 1.7g of mercaptoacetic acid when the temperature is lowered to below 50°C, and when the temperature is raised to 60°C ± 2°C, the mixture of styrene and initiator azobisisobutylheptane is added dropwise, and the mixture is composed of 104g styrene and 5.1g Initiator azobisisoheptanonitrile composition. The styrene mixture was dropped in 3.5 hours. After the drop was completed, the heat preservation reaction was carried out for 2 hours. When the temperature dropped below 30°C, 184g of 32% liquid caustic soda was added, and finally 80g of water was added to obtain a polycarboxylate superplasticizer with a solid content of 80%. .

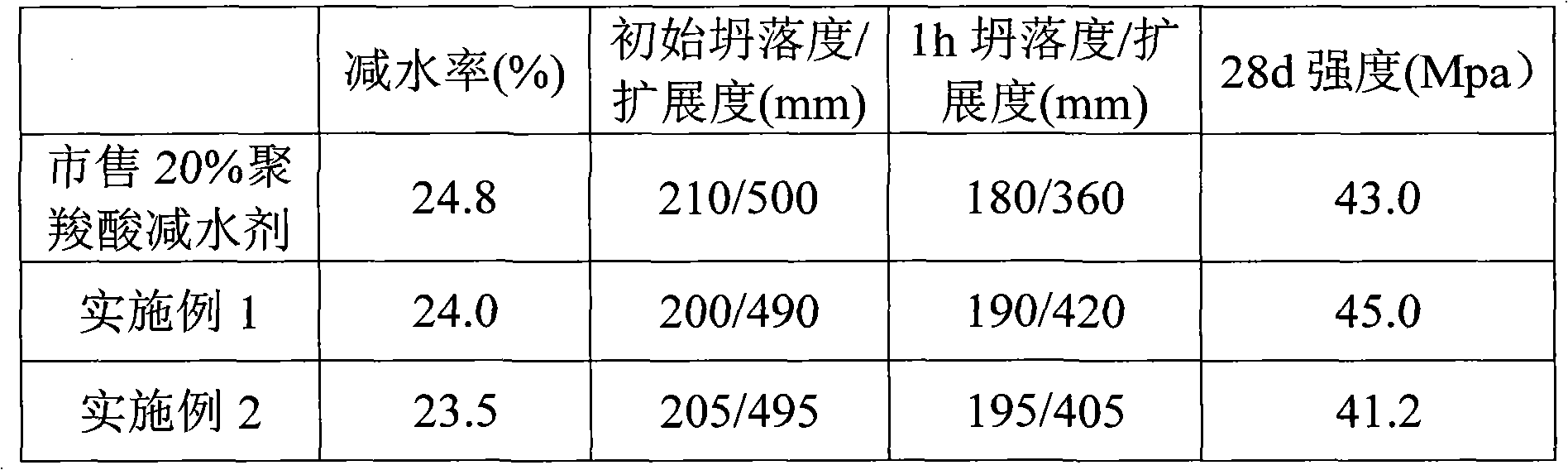

[0018] The polycarboxylate water reducer (commercially a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com