Preparation method of rare earth ion-doped large lead tungstate crystal

A technology of rare earth ions and lead tungstate, which is applied in the field of preparation of large single crystals of lead tungstate, can solve problems such as easy cracking, large stress of PWO crystals, and crystal size that cannot meet the requirements for use, so that it is not easy to crack and the preparation process is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

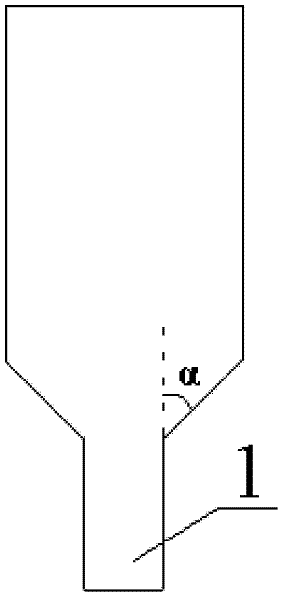

[0025] a) Made of platinum with a thickness of 0.14mm figure 1 A crucible with the structure shown and a size of Φ40×200mm, wherein: the shoulder angle at the seed crystal end α=30 degrees;

[0026] b) Using a PWO single crystal with an orientation of and a size of Φ20×50mm as a seed crystal;

[0027] c) Nd with a purity of 99.99% 2 o 3 Incorporated into PWO polycrystalline ingot, Nd 3+ The doping amount is 0.5at%;

[0028] d) will be doped with Nd 2 o 3 Put the PWO polycrystalline ingot into the platinum crucible, then put the seed crystal and close the crucible, and use the descending method for crystal growth: put the seed crystal end of the platinum crucible down into the ceramic downtube, and use alumina powder in the gap Fill, then place the downcomer on the lowering platform, raise the temperature of the furnace to 1250°C after 12 hours, and then keep it warm for 6 hours; then gradually lift the downcomer to gradually melt the raw materials in the crucible until ...

Embodiment 2

[0031] a) Made of platinum with a thickness of 0.14mm figure 1 A crucible with the structure shown and a size of Φ50×300mm, wherein: the shoulder angle at the seed crystal end α=45 degrees;

[0032] b) Using a PWO single crystal with an orientation of and a size of Φ25×60mm as the seed crystal;

[0033] c) Nd with a purity of 99.99% 2 o 3 Incorporated into PWO polycrystalline ingot, Nd 3+ The doping amount is 1.0at%;

[0034] d) will be doped with Nd 2 o 3 Put the PWO polycrystalline ingot into the platinum crucible, then put the seed crystal and close the crucible, and use the descending method for crystal growth: put the seed crystal end of the platinum crucible down into the ceramic downtube, and use alumina powder in the gap Fill, then place the downcomer on the descending platform, raise the furnace temperature to 1280°C after 15 hours, and then keep it warm for 4 hours; then gradually raise the downcomer to gradually melt the raw materials in the crucible until th...

Embodiment 3

[0036] a) Made of platinum with a thickness of 0.14mm figure 1 A crucible with the structure shown and a size of 40×40×200 mm, wherein: the shoulder angle at the seed crystal end α=30 degrees;

[0037] b) Using a PWO single crystal with an orientation of and a size of 15×15×50 mm as a seed crystal;

[0038] c) Er with a purity of 99.99% 2 o 3 Incorporated into PWO polycrystalline ingot, Er 3+ The doping amount is 0.5at%;

[0039] d) will be doped with Er 2 o 3Put the PWO polycrystalline ingot into the platinum crucible, then put the seed crystal and close the crucible, and use the descending method for crystal growth: put the seed crystal end of the platinum crucible down into the ceramic downtube, and use alumina powder in the gap Fill, then place the downcomer on the lowering platform, raise the temperature of the furnace to 1250°C after 12 hours, and then keep it warm for 6 hours; then gradually lift the downcomer to gradually melt the raw materials in the crucible u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com