Silicon refining method and refining device

A refining method and refining device technology, which are applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., and can solve problems such as inability to reach in a short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0165] (Outline of silicon refining equipment)

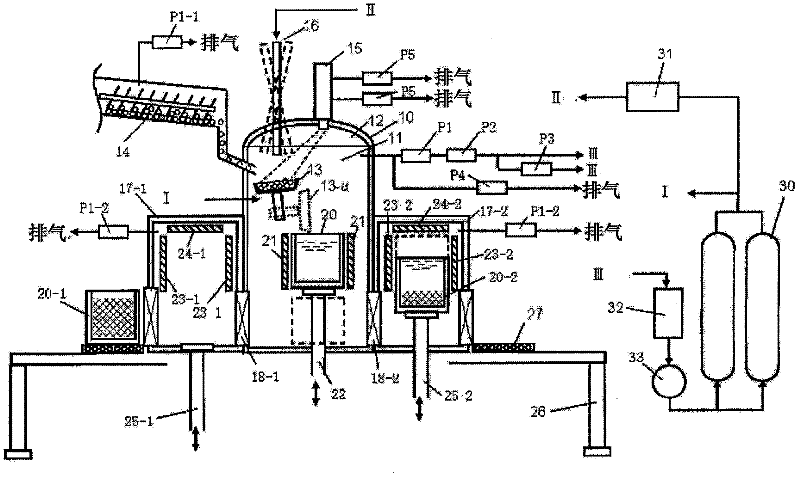

[0166] figure 1 An example of the silicon refining apparatus of the present invention is shown.

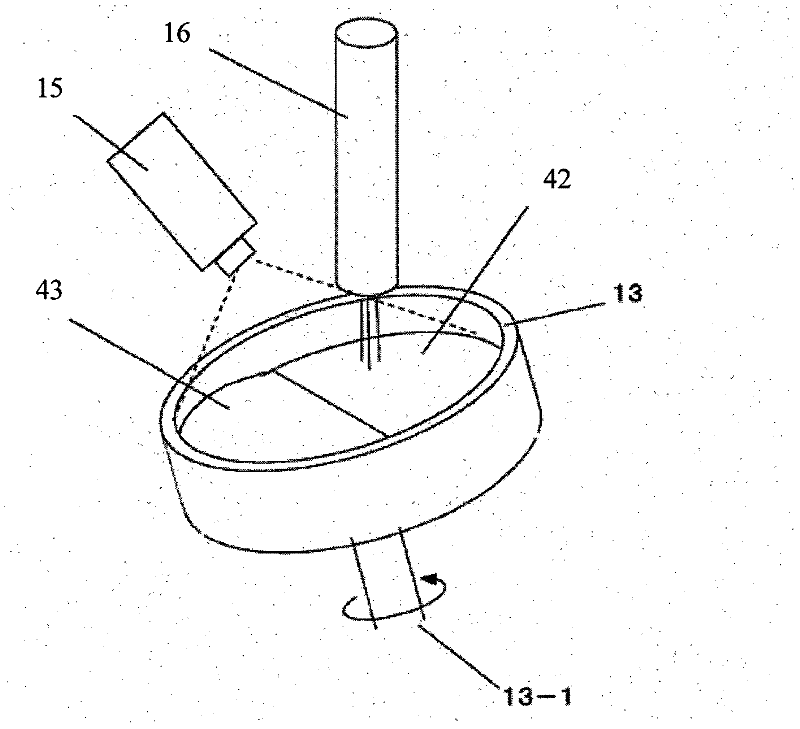

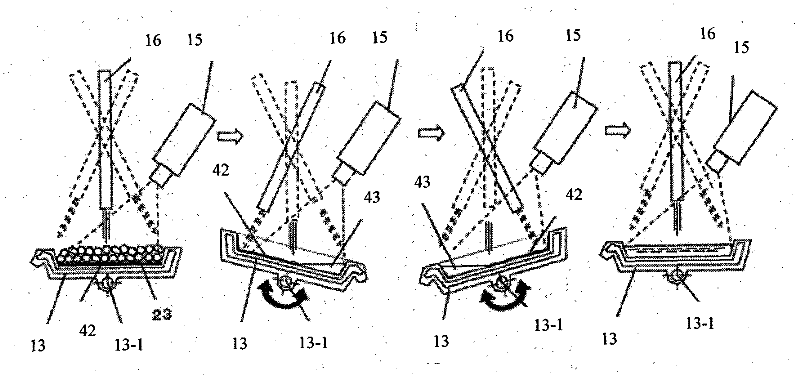

[0167] 10 is a vacuum chamber. A refining container (crucible) 13 is provided in the vacuum chamber 10. A plasma heating device 16 and an electron beam emitting device 15 are provided relative to 13. In order to supply raw silicon without destroying the atmosphere in the vacuum chamber, A vacuum screw feeder 14 is provided.

[0168] The molten silicon after the deboronation and dephosphorization treatment is discharged into the melt holding container 20 by tilting the crucible (13-a), and the melt holding container passes through the gate valve and is conveyed to the one-way solidification process by suitable conveying means. Furnace 17 (-1, 2).

[0169] The one-way solidification furnace 17 is vacuum exhausted by the exhaust pump P1-2, and has a heater 23 (-1, 2) for heat preservation and a heater 24 (-1, 2) for heating the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com